Designing an Automatic Fire Suppression System for Your Generator Room

Your generator room houses a critical, high-value asset that ensures business continuity. However, it also contains a combination of fire risks: high-voltage electricity, hot surfaces, and flammable diesel fuel. A fire in this space can lead to catastrophic asset loss and extended downtime. An automatic fire suppression system acts as a silent, 24/7 guardian designed to detect a fire at its earliest spark and extinguish it before it escalates. This is not merely about installing fire extinguishers on the wall; it is about engineering a dedicated, self-acting safety system tailored to the unique hazards of a Generator Room. This guide will walk you through the key considerations and design steps to protect your power investment effectively.

Why a Dedicated Automatic System is Essential

A Generator Room presents a specific fire challenge. Fires can start from electrical faults, overheated components, or fuel leaks, and they can develop rapidly when the room is unattended. Unlike other areas, simply using water can be dangerous due to electrical equipment. An automatic system provides the fastest possible response, operating within seconds to detect and suppress a fire. This is crucial for limiting damage to the generator, switchgear, and controls, potentially saving hundreds of thousands of dollars in equipment and preventing weeks of operational disruption. It is a cornerstone of a responsible risk management strategy for your backup power infrastructure.

Core Components of the System

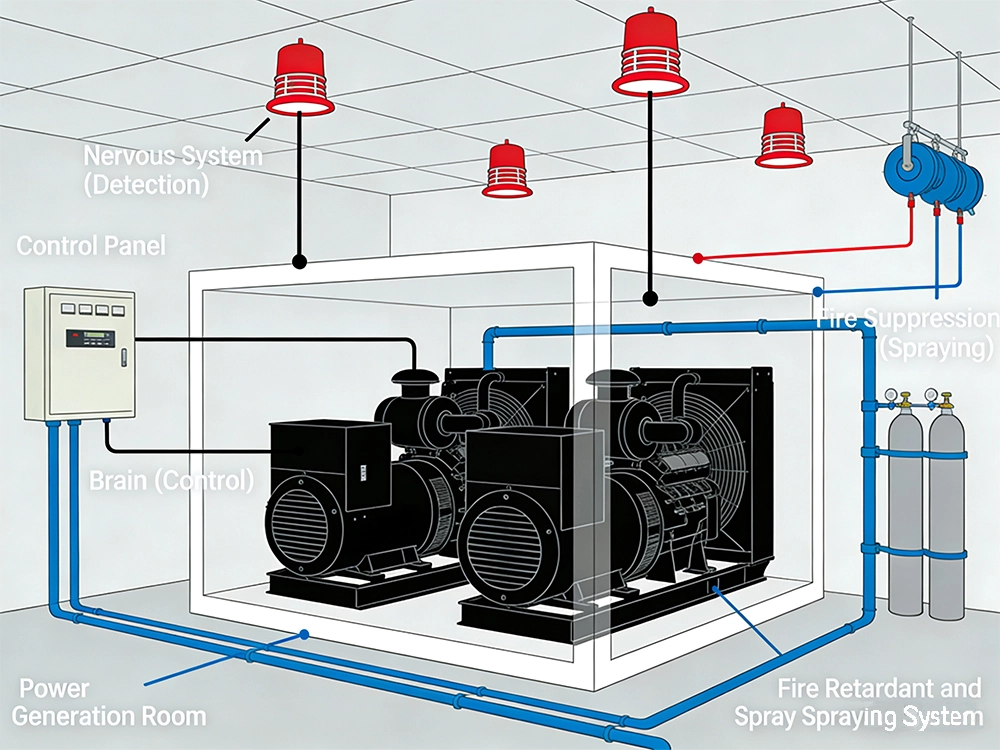

Every automatic fire suppression system consists of three main parts that work together seamlessly:

Detection System: This is the "nervous system." It includes smoke, heat, or flame detectors placed strategically around the Generator Room. These sensors continuously monitor the environment for the first signs of a fire.

Control Panel: This is the "brain." It receives signals from the detectors, processes them, and triggers the alarm and suppression sequence. Modern panels provide detailed status reports and fault warnings.

Suppression Agent & Delivery System: This is the "firefighter." It consists of pressurized cylinders containing the extinguishing agent and a network of pipes with nozzles aimed to flood the protected space quickly and uniformly when released.

Choosing the Right Suppression Agent

The choice of agent is the most critical design decision, as it must be effective yet safe for the people and equipment in the Generator Room. The common options include:

Clean Agent Gases (e.g., FM-200, Novec 1230):

How it works: These are electrically non-conductive gases that extinguish fire primarily by removing heat. They leave no residue.

Best for: Rooms with high-value electronic controls and switchgear. They are safe for personnel and allow for the quickest re-entry and equipment restart after a discharge.

Consideration: They require the room to be relatively sealed to maintain the correct concentration.

Carbon Dioxide (CO2):

How it works: CO2 extinguishes fire by displacing oxygen. It is also a clean agent.

Best for: Industrial machinery and deep-seated electrical fires.

Critical Consideration: CO2 poses a severe asphyxiation risk to humans. Its use typically requires a pre-discharge alarm and a safety delay to ensure personnel can evacuate before the gas is released. Strict safety signage and procedures are mandatory.

Wet Chemical or Water Mist Systems:

How it works: These systems suppress fire through cooling. Modern water mist systems use ultra-fine droplets that are less conductive and cause less water damage.

Best for: Areas with significant Class B (flammable liquid) risks, such as near fuel tanks or pumps. They are highly effective but may cause some secondary damage to sensitive electronics.

Key Design and Installation Steps

Designing an effective system requires a methodical approach, best executed with a certified fire protection engineer.

Conduct a Professional Hazard Analysis: A specialist will assess your specific Generator Room—its size, ventilation, equipment layout, and primary fire risks (electrical, fuel, or a combination). This analysis determines the required agent type and quantity.

Ensure Proper Zoning and Coverage: The system must be designed to protect the entire volume of the room. Nozzles must be placed to ensure the extinguishing agent reaches all corners, including under the generator skid and inside enclosures, as per manufacturer and NFPA guidelines.

Integrate Safety Interfaces: The system must be intelligently connected to other building systems. Key interfaces include:

Ventilation Shutdown: Automatically closing dampers to seal the room and prevent agent loss.

Fuel Shut-Off: Closing solenoid valves on fuel lines to cut off the fire's fuel source.

Generator Shutdown: Sending a signal to safely shut down the generator (if running).

Alarm Integration: Connecting to the building's main fire alarm system to alert security or a monitoring station.

Plan for Safe Installation and Maintenance: Installation should be performed by a licensed contractor to ensure all codes are met. After installation, the system requires regular inspection, testing, and maintenance (typically every 6-12 months) as per NFPA standards to guarantee it remains operational. Agent cylinders have a limited service life and must be hydrostatically tested and replaced periodically.

Conclusion

An automatic fire suppression system is a non-negotiable component of a well-designed, safe generator room. It is a sophisticated insurance policy that protects not just your physical equipment but also your operational resilience. The upfront investment in a properly designed system pales in comparison to the potential cost of a total loss and extended business interruption.

References

National Fire Protection Association (NFPA). (2022). NFPA 37: Standard for the Installation and Use of Stationary Combustion Engines and Gas Turbines. (Governs fire safety for engine-driven equipment).

National Fire Protection Association (NFPA). (2022). NFPA 750: Standard on Water Mist Fire Protection Systems.

ISO 14520. (2022). Gaseous fire-extinguishing systems — Physical properties and system design. International Organization for Standardization.

Viking Corporation. (2023). Technical Data Manual: Fire Suppression Systems for Hazardous Applications.