parts of diesel generator

Parameter:Please consult customer service

- Product Description

JLMECH:Your Trusted Parts of Diesel Generator Manufacturer & Supplier

At JLMECH, we understand that the reliability of a diesel generator hinges on the quality and precision of its individual components. As a leading global manufacturer and supplier of high-quality diesel generator parts, we provide critical basic components to ensure that power generation systems worldwide achieve optimal performance, extended service life, and operational safety.

Parts of Diesel Generator Description

A diesel generator is a complex integration of mechanical and electrical systems. Understanding its core components is crucial for efficient operation, maintenance, and procurement. Below is a breakdown of parts of diesel generator:

Engine Block and Core Assembly (Power Source)

- Engine Block/Cylinder Block: The foundational structure housing cylinders, coolant passages, and main bearings. JLMECH blocks are cast from high-grade iron/steel for maximum durability.

- Cylinder Head and Liners: Precision-machined heads seal combustion chambers, while replaceable liners ensure cylinder integrity under extreme pressure and heat.

- Pistons, Connecting Rods, and Crankshaft: Convert linear motion into rotational force. Our forged steel crankshafts, high-strength alloy pistons, and hardened connecting rods withstand immense stresses.

- Fuel Injection System: Uses precision components like injectors, fuel pumps (injection pumps), and high-pressure lines to achieve efficient combustion.

- Turbocharger and Aftercooler: Boosts air intake density to increase power output efficiency. JLMECH provides matched turbo systems and efficient aftercoolers.

- Cooling System: Water pumps, radiators, thermostats, and hoses manage critical engine temperatures.

- Lubrication System: Oil pumps, filters, and coolers ensure continuous clean oil flow to bearings and moving parts.

Generating System (AC Power Conversion)

- Stator: The stationary component with windings for inducing alternating current (AC). JLMECH stators feature high-quality copper windings and robust insulation (Class H standard).

- Rotor (Field Rotor): A rotating electromagnet powered by DC excitation current to create a magnetic field. Precision-balanced for smooth operation.

- Automatic Voltage Regulator (AVR): A key control unit maintaining stable output voltage under varying loads and conditions. JLMECH offers advanced AVRs compatible with major brands.

- Excitation System: Supplies DC current to rotor windings (available in brushless or static excitation systems).

- Bearings: High-capacity bearings reliably support the rotor shaft.

Control and Monitoring System (The Intelligent Brain)

- Control Panel: Houses gauges, switches, controllers, and communication interfaces, ranging from basic manual starters to complex digital touchscreens.

- Controller (Generator Control Unit - GCU): The central processor managing start/stop sequences, engine parameters (RPM, temperature, oil pressure), generator output (voltage, frequency, current), protection functions, and remote monitoring (optional). JLMECH provides controllers from brands like DSE, ComAp, and Deep Sea.

- Sensors and Transducers: Continuously monitor key parameters (speed, temperature, pressure, voltage, current) and transmit data to the controller.

- Circuit Breakers and Protection Relays: Safeguard the generator and connected loads against electrical faults (overload, short circuit, voltage/frequency anomalies).

Auxiliary Components and Safety Systems (Ensuring Operation and Protection)

- Starting System: Starter motor, starter solenoid, and batteries for engine cranking.

- Air Intake and Exhaust System: Air filters, intake manifolds, exhaust manifolds, mufflers/silencers, and flexible exhaust bellows to manage air flow and emissions.

- Fuel System: Fuel tanks (base or external), filters (primary/secondary), fuel lines, and water separators to ensure clean fuel delivery.

- Mounting System: Base frames (steel skids) and anti-vibration mounts for structural support and vibration isolation.

- Safety Devices: Critical shutdown sensors (low oil pressure, high coolant temperature, overspeed) and emergency stop buttons to prevent catastrophic damage.

Other Add-On Components (Enhancing Functionality)

- Battery Charger: Maintains starter battery health.

- Heaters: Block heaters (engine coolant) and crankcase heaters for easier cold starts.

- Transfer Switches (ATS/MTS): Automatically or manually switch loads between utility and generator power.

- Sound Attenuation Enclosures/Canopies: Significantly reduce operational noise.

- Remote Monitoring Kits: Enable remote status checks and control via network/internet.

Why Choose US?

- Cost-Effective Bulk Pricing: Competitive rates for orders above 1,000 units.

- Certified Quality: CE, ISO8528, and OEM approvals ensure global compliance.

- Fast Turnaround: 15-day lead time, even for custom batches.

- Sustainability Focus: Recyclable materials and energy-efficient production.

Packaging and Delivery

Each parts of diesel generator is sealed in anti-static packaging, with palletized bulk orders shipped via air/sea freight.

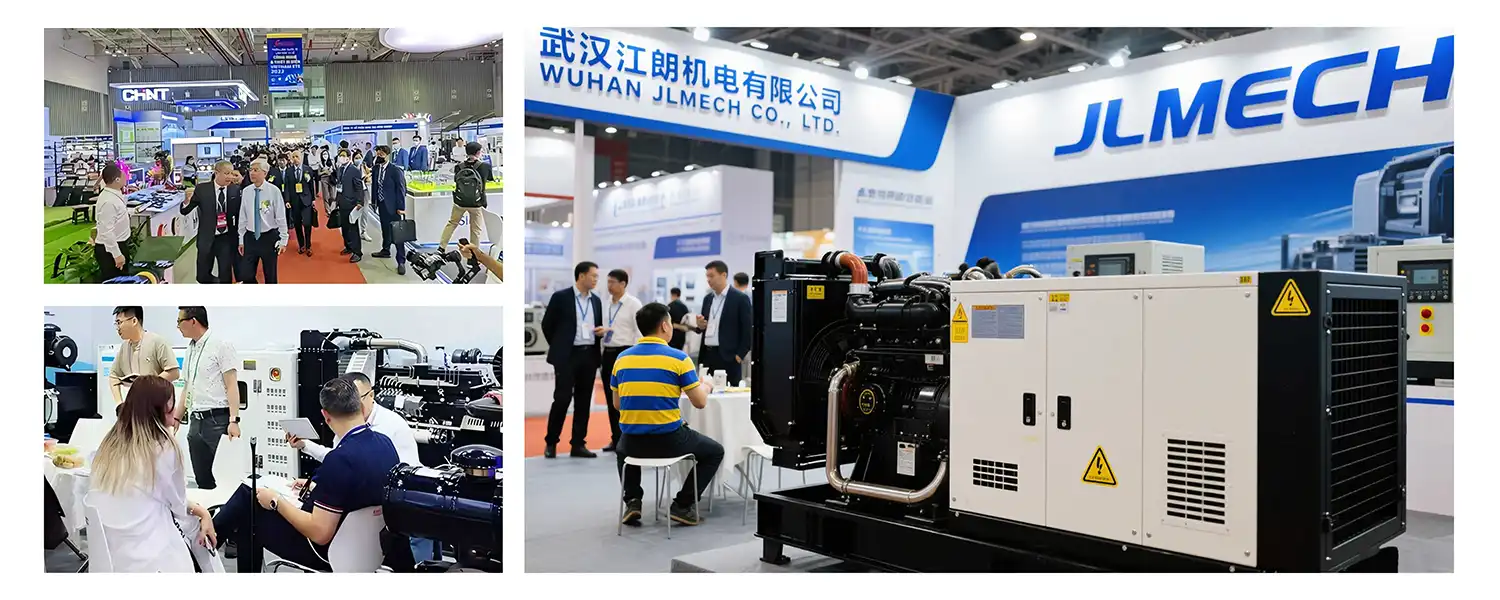

Company Profile

With 3 R&D centers, 26 global offices, and 126 technical experts, Wuhan Jlmech delivers precision-engineered filtration solutions.

Factory After-Sales Service

A 2-year warranty covers mechanical defects, supported by 24/7 technical assistance.

Certification

Our filters meet ISO9001, ISO14001, and GB/T 2820-97 standards.

Exhibitions

FAQ

Q: Do you offer samples for testing?

A: Yes! Request a free sample to evaluate performance.

Q: Can you match my OEM specifications?

A: Absolutely—share drawings, and we'll replicate dimensions and materials.

Q: What's the MOQ?

A: 500 units for standard filters; flexible terms for long-term partners.

Trusted by Global Leaders, Built for Your Needs

Whether you're a fleet manager, distributor, or industrial operator, our parts of diesel generator deliver reliability you can count on. Contact us at skala@whjlmech.com to discuss bulk orders or custom solutions.