What is the construction of a diesel generator?

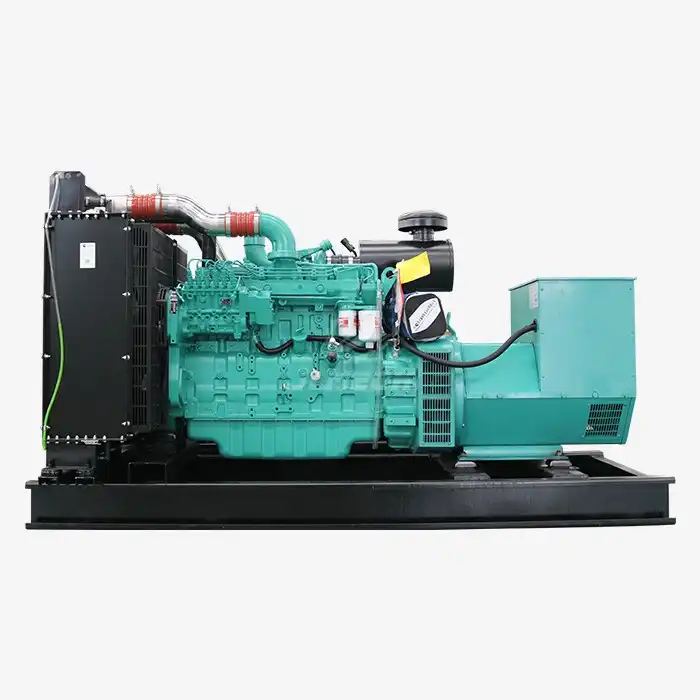

A diesel generator is more than just a machine; it is a finely integrated system that converts diesel into electrical energy through precise engineering. Understanding the diesel generator construction helps in appreciating its reliability, performance, and suitability for various applications—from backup power to prime energy source in remote locations.

At its core, every diesel generator consists of several key components that work in harmony. These include the engine, alternator, control panel, cooling system, fuel system, exhaust system, base frame, and fuel tank. Each element must be expertly designed and manufactured to ensure durability, efficiency, and safety.

Main Components

Every diesel generator set is built around several essential parts:

Engine: The source of mechanical energy.

Alternator: Converts mechanical energy into electrical energy.

Control Panel: Monitors and controls generator operation.

Cooling & Exhaust Systems: Manage heat and emissions.

Fuel System: Stores and supplies diesel to the engine.

Base Frame & Tank: Provide structural support and fuel storage.

The robustness of diesel generator construction depends on the quality and integration of these components.

Engine

The diesel engine is the heart of the generator. Its quality determines the overall lifespan and power output of the unit.

It draws in air, compresses it, and injects diesel fuel, which ignites under high pressure.

Key parts include the cylinders, pistons, fuel injectors, and crankshaft.

High-quality engines ensure better fuel efficiency, lower maintenance, and longer operational life.

Reliable diesel generator construction relies heavily on using proven and durable engine brands or self-manufactured engines with superior craftsmanship.

Alternator

The alternator—also called the generator head—converts mechanical energy from the engine into electrical power.

It consists of a rotor (rotating part) and a stator (stationary part).

As the rotor spins within the stator, it induces an electrical current through electromagnetic induction.

The quality of the copper windings, bearings, and insulation materials directly impacts efficiency and voltage stability.

A well-built alternator is essential for stable and clean power output, reflecting the sophistication of the overall diesel generator construction.

Control Panel

The control panel acts as the brain of the generator, providing user interface and operational control.

It monitors parameters such as voltage, frequency, current, and engine pressure.

Modern panels come with automatic start/stop, self-diagnosis, and remote monitoring capabilities.

Protection features include alarms and shutdowns for low oil pressure, high temperature, or overload conditions.

Intelligent control systems are a critical aspect of advanced diesel generator construction, ensuring ease of use and operational safety.

Cooling, Fuel, and Exhaust Systems

These supporting systems are vital for sustained and safe operation.

Cooling System: Prevents overheating using a radiator and coolant cycle. Critical for continuous operation.

Fuel System: Includes the fuel tank, supply pump, filters, and piping. Ensures clean and steady fuel flow to the engine.

Exhaust System: Channels away and often treats harmful gases. Includes silencers and may incorporate catalytic converters to reduce emissions.

Proper design of these systems is indispensable for efficient and environmentally conscious diesel generator construction.

Base and Tank

The base frame is the foundation that holds all components together.

Made from strong steel, it provides vibration resistance and structural integrity.

Often includes anti-vibration mounts for quieter operation.

The fuel tank may be integrated into the base or provided as a separate external unit.

A rugged base and well-designed tank contribute significantly to the durability and reliability of the generator set.

Conclusion

Understanding the inner workings of a diesel generator helps in making an informed decision tailored to your power needs. Quality of diesel generator construction directly influences performance, safety, operational cost, and service life.

At JLMECH, we combine robust engineering with stringent quality control to deliver generators that stand the test of time. Our expertise in power solutions ensures that every unit we produce meets international standards and is customizable to your specific requirements.

Whether you need a standby generator for emergency power or a prime power solution for your business, we are here to assist.

Reach out to our team for a consultation or a detailed quote. Let us help you secure a power solution that is built to last.

Email us at: skala@whjlmech.com

References

1. Johnson, M. (2022). Emergency Power Systems: A Comprehensive Guide to High-Speed Diesel Generators. Power Engineering Quarterly, 45(3), 78-92.

2. Roberts, S. (2021). Diesel Generator Set Design and Application. Industrial Energy Press.

3. Watson, A., & Davies, T. (2020). Cooling and Exhaust Systems in Diesel Generators: Design and Efficiency. Journal of Power Engineering, 14(2), 45-60.

VIEW MORE50KW 60Hz 220V diesel generator

VIEW MORE50KW 60Hz 220V diesel generator VIEW MORE100kVA Open Diesel Generator

VIEW MORE100kVA Open Diesel Generator VIEW MORETDi-Turbodirect injector diesel engine generator

VIEW MORETDi-Turbodirect injector diesel engine generator VIEW MOREElectric water-cooled generator

VIEW MOREElectric water-cooled generator VIEW MORESilent water-cooled generator

VIEW MORESilent water-cooled generator VIEW MORE20-3000kw generator

VIEW MORE20-3000kw generator VIEW MORE150kva perkins diesel generator

VIEW MORE150kva perkins diesel generator VIEW MOREsilent diesel generator 437kva

VIEW MOREsilent diesel generator 437kva