How much does it cost to run a generator every day?

Understanding the daily operating expenses of a generator is crucial for both budgeting and operational planning. While a common question, the answer is not a single figure but rather a combination of several factors. The primary focus for most businesses is on diesel generator operating costs, which are influenced by fuel consumption, load capacity, maintenance, and overall efficiency. This article breaks down these variables to help you estimate your potential expenses accurately and provides actionable strategies to manage them effectively.

Factors Influencing Daily Cost

Several key elements determine your generator’s daily expense. Being aware of these can help you make smarter operational decisions.

Fuel Consumption and Cost:

This is the most significant part of your running cost. Fuel consumption is measured in liters per hour (L/h) or gallons per hour (GPH) and varies based on:Generator size and output (kW/kVA)

Electrical load applied (e.g., 50% load vs. 100% load)

Current price of diesel in your region

Load Capacity:

Running a generator at full load consumes more fuel than running it at half load. Ideally, generators perform most efficiently at 70-80% load. Consistently low loading can lead to wet stacking and higher long-term costs.Maintenance Requirements:

Regular servicing (oil changes, filter replacements, coolant checks) prevents unexpected breakdowns and maintains fuel efficiency. Neglecting maintenance increases fuel consumption and repair costs over time.Generator Age and Technology:

Newer models with advanced engine technology and electronic control systems offer better fuel economy and lower emissions than older units.

Understanding these factors helps form a realistic expectation of diesel generator operating costs.

Real-World Calculation Examples

Let’s look at some practical scenarios to illustrate daily operating expenses. The following estimates assume a diesel price of $1.20 per liter.

Example 1: Small Business Backup Power

Generator: 50 kVA

Load: 60%

Fuel Consumption: ~8 L/h

Daily Use: 4 hours

Daily Cost: 8 L/h * 4 h * $1.20 = $38.40

Example 2: Construction Site Prime Power

Generator: 200 kVA

Load: 80%

Fuel Consumption: ~45 L/h

Daily Use: 10 hours

Daily Cost: 45 L/h * 10 h * $1.20 = $540

Example 3: Industrial Continuous Power

Generator: 500 kVA

Load: 70%

Fuel Consumption: ~95 L/h

Daily Use: 24 hours

Daily Cost: 95 L/h * 24 h * $1.20 = $2,736

These examples show how greatly diesel generator operating costs can vary depending on application and usage patterns.

Tips to Reduce Your Operating Costs

You can take several steps to minimize daily expenses without compromising reliability.

Right-Sizing Your Generator:

Avoid oversizing. A generator that’s too large will run at light load, reducing efficiency and increasing maintenance needs.Implement Load Management:

Distribute high-power devices to run at different times where possible to avoid peak loads and optimize fuel use.Invest in Regular Maintenance:

Follow the manufacturer’s service schedule. Clean filters and fresh oil keep the generator running efficiently.Use Modern Control Systems:

Advanced controllers can optimize engine performance, monitor fuel levels, and provide real-time efficiency reports.Consider Automatic Start-Stop Systems:

These systems activate the generator only when needed, reducing unnecessary runtime.

Applying these strategies can significantly lower your diesel generator operating costs over time.

Conclusion

Calculating the daily cost of running a generator involves careful consideration of fuel use, load conditions, maintenance, and generator technology. By understanding these variables and adopting cost-saving measures, you can achieve more predictable and efficient power generation operations.

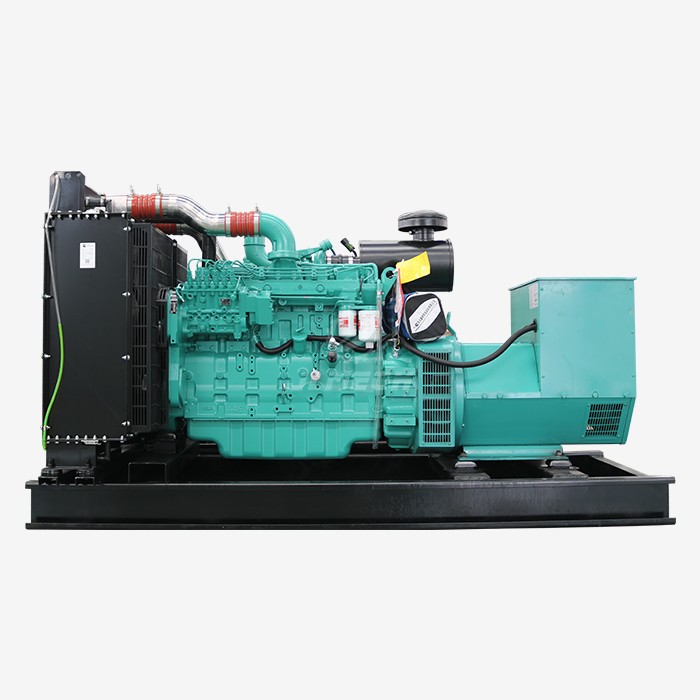

JLMECH specializes in power generation solutions with extensive expertise and an unwavering commitment to quality. Whether you need a standby, prime, or continuous power generator, our team is ready to assist you in selecting a unit that optimizes performance and minimizes operating costs.

Reach out to our experts today for a free consultation tailored to your company’s unique needs. Let us help you make a smart investment in reliable power.

Email us at: skala@whjlmech.com

Explore our range of diesel generators designed for durability, efficiency, and cost-effectiveness.

References

Johnson, M. (2022). Emergency Power Systems: A Comprehensive Guide to High-Speed Diesel Generators. Power Engineering Quarterly, 45(3), 78-92.

Peterson, L., & Clark, A. (2021). Fuel Efficiency in Industrial Generator Sets: Trends and Best Practices. International Journal of Power Management, 18(4), 112-125.

Robinson, S. (2020). Operational Costs and Performance Metrics of Modern Diesel Generators. Energy Systems Journal, 33(2), 45-60.