What are the electrical requirements for a hospital bed?

When planning hospital electrical infrastructure, understanding the requirements for a single patient bed goes far beyond simple plug specifications. Each bed is part of a complex life-support ecosystem where power reliability directly impacts patient outcomes. Modern medical facilities demand an integrated approach to thospital backup power requiremens that ensures continuous operation of critical systems. From basic monitoring to advanced life support, the electrical design must account for both normal operation and emergency scenarios where backup systems become lifelines.

Understanding Hospital Power Load Classifications

Hospitals categorize electrical loads based on their criticality to patient safety and operational continuity. This classification system directly influences how hospital backup power requirements are implemented.

Critical (Life Safety) Loads: These include illumination for exit signs, emergency lighting, and equipment essential for life support during evacuation.

Essential (Critical) Loads: This category encompasses patient care areas, especially those where power interruption would immediately endanger life. This includes:

Intensive Care Units (ICUs) and Critical Care Areas

Operating Rooms and Anesthesia Workrooms

Emergency Departments and Trauma Rooms

Cardiac Monitoring Units and Catheterization Labs

Equipment Loads: These include additional medical equipment and systems that support patient care but may have slightly less stringent backup requirements.

This classification system ensures that the most vital functions receive priority during power transitions, making proper categorization fundamental to effective hospital backup power requirements .

Essential Power Systems for Patient Care

A hospital bed's electrical environment consists of multiple interconnected systems that collectively ensure patient safety and treatment continuity.

Standard Power Outlets: Regular 120V/230V outlets for non-critical devices like patient entertainment, mobile phones, and non-essential lighting.

Emergency Power Outlets: Distinctly colored (often red) outlets connected directly to the backup power system for life-support equipment .

Medical Gas Outlet Systems: While not electrical, these are essential life-support systems often integrated with patient headwall units.

Patient Monitoring Systems: Continuous power for cardiac monitors, pulse oximeters, and other vital signs equipment.

Therapeutic Devices: Ventilators, infusion pumps, and other treatment equipment that must operate without interruption.

The integration of these systems around the patient bed creates a comprehensive care environment where power reliability cannot be compromised.

Backup Power System Components

A robust hospital backup power infrastructure consists of multiple layers of protection, each with specific response characteristics and applications.

Automatic Transfer Switches (ATS): These devices detect primary power failure and automatically switch to backup sources within seconds, ensuring minimal disruption to critical care .

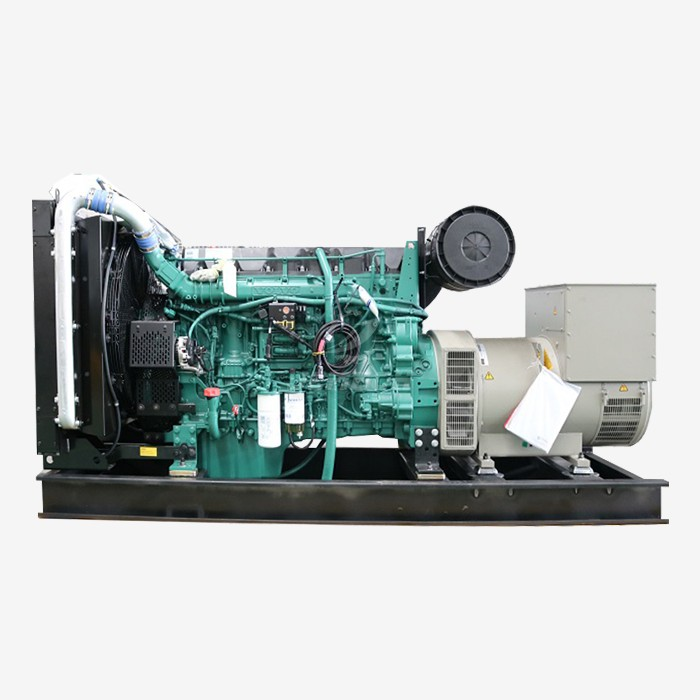

Emergency Diesel Generators: The cornerstone of hospital backup power, generators must start automatically and accept full load typically within 10-15 seconds of utility power failure .

Uninterruptible Power Supply (UPS) Systems: For loads requiring zero-interruption power (such as operating rooms and ICUs), UPS systems provide instantaneous battery-backed power until generators stabilize .

Isolated Power Systems (IPS): In wet locations and certain critical care areas, isolated power systems enhance safety by limiting potential fault currents .

This multi-layered approach to hospital backup power requirements creates a fault-tolerant system that maintains power under virtually all circumstances.

Generator Specifications and Standards

Hospital backup generators must meet rigorous specifications to ensure reliability when needed most. The specific hospital backup power requirements for generators include several critical parameters.

Capacity and Sizing: Generator capacity must accommodate all essential loads simultaneously, plus additional capacity for future expansion. For large facilities, multiple generators may provide redundancy .

Fuel Supply: Regulations often mandate minimum on-site fuel storage, typically 24-48 hours of continuous operation at full load, with provisions for emergency refueling .

Testing and Maintenance: Regular testing under load ensures generator readiness, with comprehensive maintenance schedules to prevent unexpected failures.

Location and Installation: Generator placement must consider ventilation, weather protection, fuel storage, and seismic requirements while maintaining accessibility for maintenance.

Noise and Emissions Control: Especially in urban environments, acoustic treatment and emissions controls ensure generators comply with environmental regulations.

These specifications ensure that when primary power fails, the backup system performs flawlessly regardless of duration or weather conditions.

Design Considerations and Implementation

Successful implementation of hospital backup power requires careful planning and coordination across multiple disciplines.

Load Banking: Periodic testing with simulated loads verifies system performance under conditions mimicking actual power failure.

System Commissioning: Comprehensive testing of all backup power components ensures proper integration and operation before system acceptance.

Staff Training and Procedures: Clinical and engineering staff require training on backup power operation, limitations, and procedures during extended outages.

Maintenance Contracts: Given the critical nature of these systems, specialized maintenance contracts with rapid response guarantees are essential.

These implementation considerations transform theoretical hospital backup power requirements into operational reality that stands ready when needed.

Compliance with International Standards

Hospital backup power systems must comply with numerous international standards and codes that define minimum requirements for reliability and safety.

ISO Standards: The ISO 8528 series covers the performance and design of generator sets .

National Electrical Codes: These typically define requirements for emergency power systems in healthcare facilities.

Industry-Specific Standards: Organizations like NFPA (National Fire Protection Association) provide detailed guidelines for emergency power system installation and maintenance.

Local Regulations: Municipal building codes often incorporate additional requirements specific to geographical risks like earthquakes, floods, or extreme weather.

Compliance with these standards represents the minimum threshold for hospital backup power requirements, with many institutions implementing systems that exceed these benchmarks.

Conclusion

The electrical requirements for a hospital bed extend far beyond the simple outlet on the wall. They represent an integrated, multi-layered system designed to ensure absolute power reliability for patient care. From the instant response of UPS systems to the sustained power of diesel generators, each component plays a vital role in maintaining life-support systems during power interruptions. Understanding these complex hospital backup power requirements is essential for designing, installing, and maintaining systems that truly protect patients when utility power fails.

Our team specializes in providing backup power solutions that meet the rigorous demands of healthcare facilities. For assistance with your hospital power needs, contact our experts at skala@whjlmech.com.

References

International Organization for Standardization. (2018). Reciprocating internal combustion engine driven generating sets — Part 1: Application, ratings and performance (ISO 8528-1:2018).

National Fire Protection Association. (2020). Standard for Emergency and Standby Power Systems (NFPA 110).

Generator Manufacturers Association. (2021). Guidelines for Rating and Application of Generator Sets. GMA Technical Publication TP-101.

Johnson, M. (2022). Emergency Power Systems: A Comprehensive Guide to High-Speed Diesel Generators. Power Engineering Quarterly, 45(3), 78-92.