How to make a diesel engine run cooler?

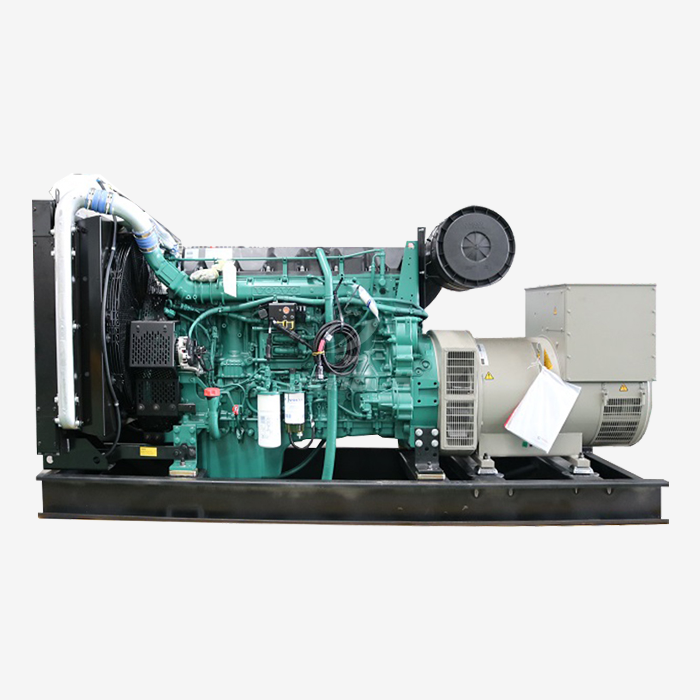

For businesses and operators relying on diesel generators, maintaining optimal operating temperatures isn't just a technical consideration–it's a crucial factor influencing efficiency, longevity, and operational costs. When a diesel engine runs too hot, it risks accelerated component wear, reduced power output, increased fuel consumption, and potential catastrophic failure. Understanding how to manage engine temperature effectively begins with recognizing the critical role of the Diesel cooling fan and its integration within the broader cooling system. This comprehensive guide explores practical strategies to enhance cooling performance, ensuring your diesel generator operates reliably under demanding conditions.

Understanding Cooling System Fundamentals

A diesel engine's cooling system manages the immense heat generated during combustion–with cylinder temperatures reaching up to 2,000°C. The system maintains components within an optimal range of 80-95°C through careful heat transfer processes. Coolant circulates through engine passages, absorbing heat before flowing to the radiator where the Diesel cooling fan forces air through fine fins to dissipate heat to the atmosphere. This process maintains proper clearances between moving parts, preserves lubricating oil properties, prevents thermal stress damage, and ensures complete fuel combustion for maximum efficiency.

Optimizing Cooling Fan Technology

The Diesel cooling fan represents one of the most significant opportunities for improving temperature management. Traditional fixed-speed fans constantly consume engine power regardless of actual cooling needs, but several advanced alternatives offer superior performance:

Viscous Clutch Fans: These systems use temperature-sensitive clutches filled with silicon oil that engage and disengage based on heat load. This allows fan operation only when needed, reducing parasitic power loss and improving fuel efficiency.

Electronically Controlled Fans: Modern systems employ electronic controls using temperature sensors and engine management systems to precisely regulate fan speed. These provide optimal cooling with minimal power consumption and noise emissions.

Electric Fans: Separate from engine-driven systems, these fans use individual electric motors controlled by thermal switches, allowing operation independent of engine speed–particularly beneficial for generators maintaining constant RPM for frequency stability.

Upgrading to an intelligent Diesel cooling fan system can reduce fan power consumption by up to 50% while improving temperature regulation.

Ensuring Proper Installation and Clearance

Correct installation of cooling components significantly impacts performance. The Diesel cooling fan should be positioned as close as practical to the radiator while maintaining sufficient clearance–typically 15-20mm between fan blades and the shroud. This precise positioning maximizes airflow through the radiator core rather than around it. Additionally, the fan should be carefully aligned with the radiator's center to ensure even air distribution across the entire surface. Proper belt tensioning is equally crucial–over-tightened belts accelerate wear on bearings, while loose belts slip and reduce fan efficiency. Modern generators often incorporate automatic tensioners or marked adjustment points to simplify this critical maintenance task.

Implementing Regular Maintenance Practices

Proactive maintenance prevents most cooling-related issues before they cause overheating:

Fan Inspection: Regularly check fan blades for cracks, erosion, or deformation. Ensure mounting components are secure and look for any signs of imbalance that could lead to vibration and premature failure.

Cooling System Cleaning: Periodically clean radiator fins of debris that restricts airflow. For generators operating in dusty environments, more frequent cleaning may be necessary. Consider compressed air or low-pressure water flushing, taking care not to damage delicate fins.

Belt and Bearing Maintenance: Inspect drive belts for cracks, glazing, or fraying. Check pulley bearings for excessive play or noise, and follow manufacturer recommendations for lubrication intervals.

System Testing: Verify proper operation of fan clutches and control systems to ensure they engage and disengage at appropriate temperatures.

Upgrading Coolant and Pump Capacity

Beyond the Diesel cooling fan itself, supporting components play vital roles in temperature management:

High-Performance Coolants: Modern coolant formulations containing organic acid technology (OAT) provide superior heat transfer characteristics and extended service life compared to conventional ethylene glycol-based products. These specialized coolants also offer enhanced corrosion protection for aluminum components.

Coolant Flow Optimization: In some applications, increasing coolant flow rates can improve heat dissipation. Research indicates that optimizing coolant flow through water jacket redesign can significantly enhance cooling efficiency. However, such modifications must be carefully engineered to avoid creating other issues.

System Pressure Enhancement: Increasing cooling system pressure raises the boiling point of the coolant. Modern systems typically operate at 0.7-0.9 bar, allowing coolant temperatures to reach 115°C without boiling when using proper coolant formulations.

Enhancing Overall System Design

Comprehensive cooling system improvement extends beyond individual components:

Radiator Optimization: Ensure radiator size matches heat rejection requirements. The radiator core should have sufficient surface area, and the coolant circuit should promote laminar flow for maximum heat transfer. Upgrading to a high-efficiency radiator with turbulator tubes and louvered fins can improve thermal performance by 15-20%.

Auxiliary Cooling Systems: For generators operating in extreme conditions, supplemental cooling options such as separate circuit aftercoolers or auxiliary radiators can provide additional heat rejection capacity without overloading the primary cooling system.

System Integration: Advanced cooling systems employ integrated controls that coordinate the Diesel cooling fan with other thermal management components, creating a cohesive system that responds dynamically to changing operating conditions.

Implementing Operational Best Practices

How you operate your diesel generator significantly impacts its thermal performance:

Load Management: Avoid sustained operation above 90% of rated capacity, especially in high ambient temperatures. The Diesel cooling fan and radiator have finite heat rejection capabilities that may be exceeded during continuous peak loading.

Environmental Considerations: When installing generators, ensure adequate ventilation space around the unit–typically at least 1 meter clearance on all sides. Never operate a generator in an enclosed space without proper ducting.

Warm-Up and Cool-Down Procedures: Allow the engine to reach normal operating temperature before applying heavy loads. Similarly, let the unit run at low load for a few minutes before shutdown to dissipate residual heat gradually.

Temperature Monitoring: Install accurate temperature gauges rather than relying solely on warning lights. Monitoring actual temperatures helps identify developing issues before they become critical problems.

Conclusion

Optimizing diesel engine operating temperature requires a systematic approach addressing both component performance and system integration. From selecting the appropriate Diesel cooling fan technology to implementing comprehensive maintenance protocols, each element contributes to more effective heat management. The benefits extend beyond simply preventing overheating–they include improved fuel efficiency, reduced emissions, extended engine life, and enhanced operational reliability. By understanding and applying these principles, you can ensure your diesel generator delivers maximum performance when you need it most.

Our engineering team specializes in helping clients optimize cooling systems for their specific operating conditions. For personalized technical assistance, contact our experts at skala@whjlmech.com.

References

Johnson, M. (2022). Emergency Power Systems: A Comprehensive Guide to High-Speed Diesel Generators. Power Engineering Quarterly, 45(3), 78-92.

Xu, N. (2020). New Technologies and Applications for Diesel Generator Sets.

Yang, W. (2010). Research on Hydraulic Drive Device of Electro-Hydraulic Hybrid Drive Cooling System for Construction Machinery.