What is the cooling system of a diesel engine?

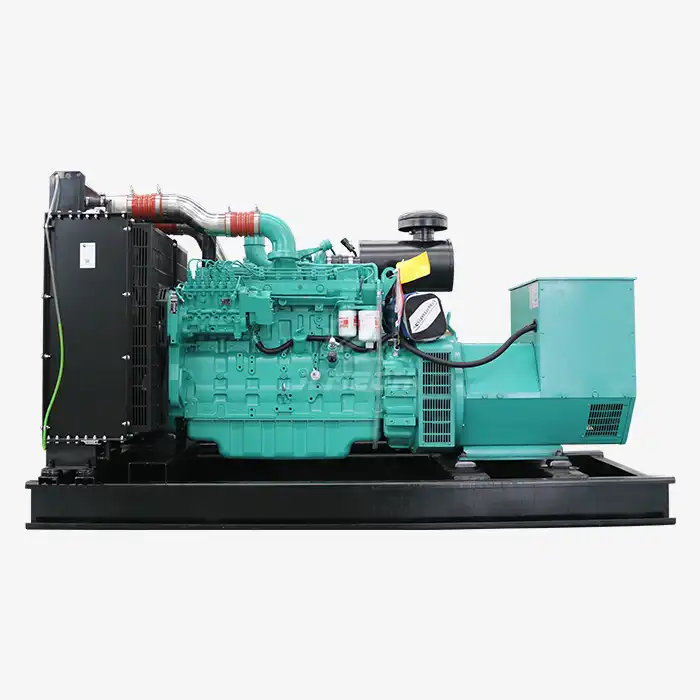

For anyone relying on diesel generators for prime or backup power, understanding the cooling system is crucial for ensuring operational reliability and equipment longevity. The cooling system plays a vital role in maintaining the diesel engine at its optimal working temperature, directly impacting efficiency, emissions, and service life. At the heart of this system is the Diesel cooling fan, a component responsible for dissipating the immense heat generated during combustion. Without a properly functioning cooling system, diesel engines would rapidly overheat, leading to reduced performance, increased fuel consumption, and potentially catastrophic engine failure. This comprehensive guide explores the fundamentals of diesel engine cooling systems, with particular focus on the role and types of Diesel cooling fan units that keep your power supply running smoothly.

Cooling System Fundamentals

Diesel engines convert fuel into mechanical energy through controlled combustion, a process that generates extremely high temperatures reaching up to 2,000°C (3,632°F) in the cylinders. The cooling system's primary function is to manage this heat, maintaining engine components within their optimal operating range of 80-95°C (176-203°F).

Heat Transfer Process: The system works by circulating coolant through passages in the engine block and cylinder head, where it absorbs heat from metal surfaces. This heated coolant then flows to the radiator, where the Diesel cooling fan forces air through fine fins, transferring heat from the coolant to the atmosphere.

System Importance: Proper cooling maintains optimal clearances between moving parts, preserves lubricating oil properties, prevents thermal stress damage to components, and ensures complete fuel combustion for maximum efficiency.

Cooling Mediums: While liquid-cooled systems dominate industrial applications, some smaller generators utilize air-cooling systems with fins and fans directly mounted to the engine.

Key System Components

A diesel engine's cooling system comprises several integrated components that work together to regulate temperature effectively:

Radiator: Constructed with narrow tubes and fins that provide maximum surface area for heat exchange between hot coolant and ambient air. Modern radiators are typically aluminum or copper construction, balancing thermal conductivity with durability.

Water Pump: This centrifugal pump, typically belt-driven from the engine crankshaft, circulates coolant throughout the system at rates proportional to engine speed. It ensures consistent flow through engine passages and the radiator core.

Thermostat: Acting as a temperature-controlled valve, the thermostat remains closed during engine warm-up to facilitate quick heating and opens once optimal temperature is reached to allow full coolant circulation through the radiator.

Coolant: Modern cooling fluids are typically ethylene or propylene glycol mixtures with water, providing not only heat transfer but also freeze protection, boil-over resistance, and corrosion inhibition.

Diesel cooling fan: As a critical airflow component, the cooling fan draws ambient air through the radiator core to accelerate heat dissipation. These fans may be mechanically driven, electrically powered, or employ advanced clutch systems for optimal efficiency.

Cooling System Types

Diesel engines employ two primary cooling methods, each with distinct advantages and applications:

Air Cooling Systems:

Utilize airflow across fins integrated into the engine cylinder and head to directly transfer heat to the atmosphere.

Employ Diesel cooling fan units to generate necessary airflow across these finned surfaces.

Offer simplicity, reduced maintenance, and elimination of coolant-related issues.

Typically found in smaller applications and specific industrial environments where water scarcity or freezing conditions pose challenges.

Liquid Cooling Systems:

Use coolant circulating through engine passages and a radiator to transfer heat.

Incorporate a Diesel cooling fan to pull air through the radiator for heat rejection.

Provide superior temperature control and heat dissipation capacity for larger engines.

Dominate in medium and large generator sets where stable operating temperatures are critical for performance and emissions compliance.

Cooling Fan Types and Operation

The Diesel cooling fan is not a one-size-fits-all component, with several distinct technologies employed across different generator sizes and applications:

Mechanical Direct-Drive Fans: These simplest designs connect directly to the engine via belts and pulleys, with fan speed directly proportional to engine RPM. While reliable and cost-effective, they constantly consume engine power and provide excessive cooling during cold weather.

Viscous (Silicon Oil) Clutch Fans: These sophisticated systems use a temperature-sensitive clutch mechanism filled with silicon oil between the drive pulley and fan. The clutch engages and disengages based on heat load, allowing the fan to operate only when needed, thus reducing parasitic power loss and improving fuel efficiency.

Electronically Controlled Fans: Modern large generators often feature Diesel cooling fan units with electronic controls that use temperature sensors and engine management systems to precisely regulate fan speed. These provide optimal cooling with minimal power consumption and noise emissions.

Electric Fans: Separate from engine-driven systems, these fans use individual electric motors controlled by thermal switches. This allows operation independent of engine speed, particularly beneficial for generators that maintain constant RPM for frequency stability.

Advanced Fan Technology

Recent innovations have significantly improved the efficiency and functionality of cooling fan systems:

Smart Fan Control Systems: Electronically controlled viscous fan clutches and electromagnetic clutch fans enable precise temperature management by responding to multiple inputs including coolant temperature, ambient conditions, and engine load.

Intelligent Speed Control: Modern systems can reduce fan speed during low-load operation, decreasing noise and improving fuel efficiency while maintaining adequate cooling.

Enhanced Materials: Modern fan blades increasingly utilize composite materials like reinforced plastics rather than traditional metals, reducing weight while maintaining strength and corrosion resistance.

Optimized Blade Designs: Advanced computational fluid dynamics has enabled aerodynamically superior blade profiles that move more air with less noise and reduced power consumption.

Maintenance Guidelines

Proper maintenance of the cooling system, particularly the Diesel cooling fan, is essential for preventing unscheduled downtime:

Regular Inspection: Visually check fan blades for cracks, erosion, or deformation, and ensure mounting components are secure. Verify belt tension and condition on mechanically driven systems.

Bearing Lubrication: Follow manufacturer recommendations for fan bearing lubrication intervals to prevent premature failure.

Cleaning Protocol: Regularly clean fan blades and radiator surfaces of debris that can impair airflow and cooling efficiency.

System Testing: Periodically verify proper operation of fan clutches and control systems to ensure they engage and disengage at appropriate temperatures.

Troubleshooting Common Issues

Recognizing and addressing cooling system problems early can prevent more serious engine damage:

Overheating Conditions: Often caused by faulty fan clutches, slipping drive belts, radiator blockage, or malfunctioning thermostats. Immediate attention is required to prevent engine damage.

Coolant Leaks: Can develop at hose connections, water pump seals, radiator seams, or engine gaskets, requiring prompt repair to maintain proper coolant levels and prevent air intrusion.

Unusual Fan Noises: Typically indicate bearing wear, blade imbalance, or contact with surrounding components. These issues should be investigated immediately to prevent catastrophic fan failure.

Insufficient Warming: May result from thermostats stuck in the open position, preventing the engine from reaching its optimal operating temperature and reducing fuel efficiency.

Conclusion

The diesel engine cooling system represents a sophisticated thermal management solution that is fundamental to generator performance, efficiency, and service life. From basic mechanical fans to advanced intelligent cooling systems with precisely controlled Diesel cooling fan technology, proper cooling system design and maintenance directly impact your power generation capabilities. Understanding these systems enables better operational decisions, preventive maintenance planning, and more informed generator selection. As diesel technology continues evolving toward greater efficiency and lower emissions, the role of advanced cooling systems and particularly smart Diesel cooling fan technology becomes increasingly critical for optimal generator performance across all operating conditions.

Our technical team specializes in helping clients select and maintain the ideal cooling solutions for their specific generator applications. For personalized assistance with your power generation needs, contact our experts at skala@whjlmech.com.

References

- Johnson, M. (2022). Emergency Power Systems: A Comprehensive Guide to High-Speed Diesel Generators. Power Engineering Quarterly, 45(3), 78-92.

- Xu, N. (2020). New Technologies and Applications for Diesel Generator Sets.

- Yiche Auto Encyclopedia. (2024). Composition of Diesel Engine Cooling Systems.

- Yang, W. (2010). Research on Hydraulic Drive Device of Electro-Hydraulic Hybrid Drive Cooling System for Construction Machinery.

- Yiche Auto. (2020). Engine System Composition of Diesel Generator Sets.