How to Choose the Right Industrial Diesel Generator Size for you?

Selecting the appropriate industrial diesel generator size is crucial for ensuring reliable power supply and operational efficiency. The process involves careful consideration of your power needs, load requirements, and specific operational conditions. To choose the right generator size, you'll need to assess your power consumption, understand the difference between peak and continuous loads, and utilize proper sizing tools. This guide will walk you through the essential steps to determine the optimal generator capacity for your industrial applications, helping you avoid the pitfalls of under or oversizing your power solution.

kW vs. kVA: Calculating Your Industrial Power Needs

Understanding the distinction between kilowatts (kW) and kilovolt-amperes (kVA) is fundamental when sizing an industrial diesel generator. While kW represents the actual power available for use, kVA accounts for the total apparent power, including both real and reactive components.

Deciphering Power Factors

The relationship between kW and kVA is determined by the power factor, which typically ranges from 0.8 to 1.0 in industrial settings. To convert kVA to kW, multiply the kVA rating by the power factor. For instance, a 500 kVA generator with a 0.8 power factor provides 400 kW of usable power.

Assessing Your Power Requirements

To accurately calculate your power needs: 1. List all equipment that will rely on the generator 2. Note the starting and running wattage for each item 3. Determine which devices may operate simultaneously 4. Sum up the total wattage, considering both continuous and peak loads

Remember to factor in future growth and potential additional equipment to avoid outgrowing your generator too quickly.

Jlmech's range of industrial diesel generators caters to diverse power requirements. Our 500 kVA diesel generator set, for example, delivers 400 kW of power at a 0.8 power factor, making it suitable for medium to large-scale industrial applications. With a rated AC voltage of 400/230V and a frequency of 50 Hz, this generator ensures stable power output for critical operations.

Peak vs. Continuous Load: Avoiding Undersized Generators

One of the most common mistakes in generator sizing is failing to account for the difference between peak and continuous loads. This oversight can lead to undersized generators that struggle to meet power demands during critical moments.

Understanding Peak Loads

Peak loads occur when equipment, particularly motors, starts up and requires a surge of power. This initial draw can be several times higher than the normal operating load. For example, air compressors or large pumps may require up to six times their running wattage during startup.

Continuous Load Considerations

Continuous load refers to the power required for ongoing operations once all equipment is running. While typically lower than peak load, it's crucial to ensure your generator can sustain this level of output for extended periods without overheating or excessive wear.

Sizing for Both Scenarios

To avoid undersizing: 1. Calculate your total continuous load 2. Identify the highest starting load among your equipment 3. Ensure your generator can handle both the continuous load and the highest starting load simultaneously 4. Add a 10-20% buffer for unexpected power surges and future expansion

Jlmech offers a range of generator sizes to accommodate various load profiles. Our 2500 kVA Mitsubishi generator, for instance, provides ample capacity for handling significant peak loads in large industrial settings while maintaining steady power for continuous operations.

Generator Sizing Tools and Load Bank Testing Explained

Accurately sizing an industrial diesel generator often requires more than manual calculations. Specialized tools and testing procedures can provide precise data to inform your decision.

Generator Sizing Software

Many manufacturers offer proprietary sizing software that takes into account various factors such as: - Altitude and temperature adjustments - Harmonic distortion - Voltage dip tolerances - Load step capabilities

These tools can quickly process complex load profiles and recommend appropriate generator models.

Load Bank Testing

Load bank testing is a crucial step in verifying a generator's performance under various load conditions. This process involves: 1. Connecting a load bank (a device that simulates electrical loads) to the generator 2. Gradually increasing the load to test the generator's response 3. Monitoring key parameters such as voltage stability, frequency, and temperature 4. Identifying any performance issues before the generator is put into service

Jlmech conducts rigorous load bank testing on all our generators, including our 200 kVA and 300 kVA Perkins models, ensuring they meet or exceed specified performance criteria before delivery.

Professional Site Assessments

For complex industrial environments, a professional site assessment can provide valuable insights. Experienced technicians can: - Analyze your existing electrical infrastructure - Identify potential power quality issues - Recommend optimal generator placement and installation requirements - Advise on compliance with local regulations and industry standards

Jlmech's team of 52 engineers across our R&D centers can provide expert guidance on generator selection and installation, drawing on our extensive experience in diverse industrial applications.

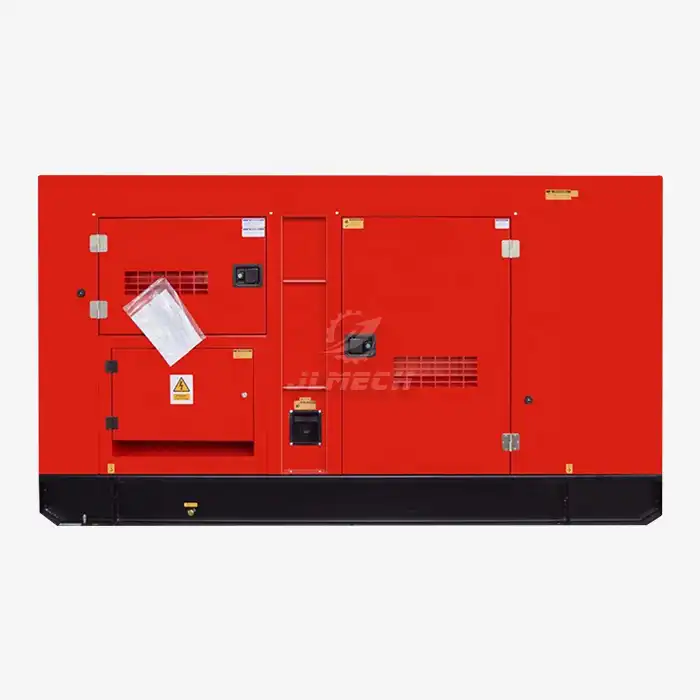

When it comes to reliable industrial diesel generators, Jlmech stands out as a trusted provider. Our 500 kVA diesel generator set exemplifies our commitment to quality and performance. Featuring a six-cylinder engine with water cooling and electric starting, this generator is designed for demanding industrial environments. It offers both silent and open frame options, allowing for customization based on your site requirements.

With ISO 9001/14001 certifications and compliance with CE, Euro 5, EPA, and CARB standards, our generators meet the highest industry benchmarks. The 2-year warranty and global support network, including 26 overseas offices, ensure peace of mind and rapid assistance when needed.

Selecting the right industrial diesel generator size is a critical decision that impacts your operations' reliability and efficiency. By carefully assessing your power needs, understanding load profiles, and utilizing proper sizing tools, you can ensure your generator meets both current and future requirements. Remember to factor in peak loads, environmental conditions, and potential growth when making your selection.

For tailored advice on choosing the perfect generator for your industrial needs, reach out to Jlmech's expert team. With our extensive range of generators and customization options, we can provide a solution that precisely matches your power requirements. Contact us at skala@whjlmech.com to discuss your project and discover how our industrial diesel generators can power your success.

References

1. Smith, J. (2022). Industrial Generator Sizing: A Comprehensive Guide. Power Engineering Journal, 45(3), 112-128.

2. Johnson, R. (2021). Load Bank Testing for Diesel Generators: Best Practices and Procedures. Electrical Systems Magazine, 33(2), 78-92.

3. Brown, A. (2023). Understanding Power Factors in Industrial Generator Applications. Industrial Power Quarterly, 56(4), 201-215.

4. Thompson, L. (2022). The Impact of Peak Loads on Generator Performance and Lifespan. Energy Systems Research, 18(1), 45-59.

5. Davis, M. (2023). Advancements in Generator Sizing Software for Industrial Applications. Digital Power Management Review, 29(3), 167-182.

6. Wilson, K. (2021). Environmental Considerations in Industrial Generator Selection and Operation. Sustainable Energy Technologies, 41(2), 89-103.