Best Lubricants for the Industrial Diesel Generator Engine

Selecting the right lubricant for your industrial diesel generator is crucial for maintaining optimal performance and longevity. High-quality engine oils protect vital components, reduce friction, and help dissipate heat effectively. For industrial generators, synthetic oils with a viscosity grade of 15W-40 or 10W-30 are often recommended. These multi-grade oils provide excellent protection across a wide temperature range, ensuring smooth operation in various conditions. Additionally, oils meeting API CK-4 or FA-4 specifications are designed to withstand the high temperatures and pressures encountered in modern diesel engines, making them ideal for industrial applications.

When choosing a lubricant, consider factors such as the generator's operating environment, load capacity, and manufacturer recommendations. Premium lubricants may come with a higher upfront cost but can significantly extend engine life and reduce maintenance needs. It's also worth noting that some specialized industrial diesel generator oils contain additives to combat soot formation and acid buildup, which are common issues in diesel engines operating under heavy loads.

What oil viscosity is best for industrial diesel generators?

The optimal oil viscosity for industrial diesel generators depends on several factors, including ambient temperature, engine design, and operational demands. Generally, multi-grade oils are preferred due to their ability to maintain proper viscosity across a wide temperature range.

Cold Climate Considerations

In colder climates, a lower first number in the viscosity grade (e.g., 5W or 10W) is beneficial. This ensures easier cold starts and adequate oil flow during initial engine warm-up. For instance, a 5W-40 oil might be suitable for generators operating in regions with harsh winters.

Hot Climate and Heavy-Duty Applications

For hot climates or heavy-duty applications where engines run at high temperatures for extended periods, oils with higher second numbers (e.g., 40 or 50) are often recommended. A 15W-40 oil is a common choice for many industrial generators, offering good protection in both moderately cold and hot conditions.

It's worth noting that some modern industrial diesel generators are designed to operate with lower viscosity oils like 10W-30 or even 5W-30. These can improve fuel efficiency without compromising engine protection, thanks to advancements in oil formulation technology.

Synthetic vs. conventional oils: Which extends engine life?

When it comes to prolonging the life of your industrial diesel generator, the choice between synthetic and conventional oils can have a significant impact. Both types have their merits, but synthetic oils generally offer superior performance and protection.

Advantages of Synthetic Oils

Synthetic oils are engineered to provide enhanced protection against wear, oxidation, and thermal breakdown. They maintain their viscosity better at extreme temperatures, ensuring consistent lubrication even under harsh operating conditions. This stability translates to reduced engine wear and potentially longer intervals between oil changes.

Performance of Conventional Oils

While conventional oils can provide adequate protection for some applications, they may struggle to match the performance of synthetic oils in high-stress environments. They tend to break down faster at high temperatures and may not flow as easily in cold conditions, potentially leading to increased wear during cold starts.

For industrial diesel generators that often operate under heavy loads or in challenging environments, synthetic oils offer several key benefits:

- Better resistance to oxidation and thermal breakdown

- Improved low-temperature fluidity for cold starts

- Enhanced protection against sludge and deposit formation

- Potential for extended oil drain intervals (with proper monitoring)

While synthetic oils typically come with a higher upfront cost, their superior performance can lead to long-term savings through reduced wear, fewer oil changes, and potentially improved fuel efficiency. For critical power applications where reliability is paramount, the investment in synthetic oil can pay dividends in extended engine life and reduced downtime.

How often should you change diesel generator oil?

Determining the optimal oil change interval for your industrial diesel generator is crucial for maintaining performance and reliability. While general guidelines exist, the specific frequency can vary based on several factors.

Factors Affecting Oil Change Frequency

Several variables influence how often you should change the oil in your diesel generator:

- Operating hours and load conditions

- Environmental factors (dust, humidity, temperature extremes)

- Oil quality and type (synthetic vs. conventional)

- Engine condition and age

- Fuel quality

General Guidelines

As a general rule, many manufacturers recommend changing the oil in industrial diesel generators every 250 to 500 operating hours or at least once per year, whichever comes first. However, these are baseline recommendations and may need adjustment based on your specific circumstances.

Optimizing Oil Change Intervals

To optimize your oil change schedule, consider implementing an oil analysis program. Regular oil analysis can provide valuable insights into engine health and oil condition, allowing you to extend oil change intervals safely or identify potential issues before they lead to costly repairs.

For generators used in standby applications with limited run time, it's important to note that oil can degrade even when the engine isn't running. In these cases, annual oil changes are typically recommended regardless of operating hours.

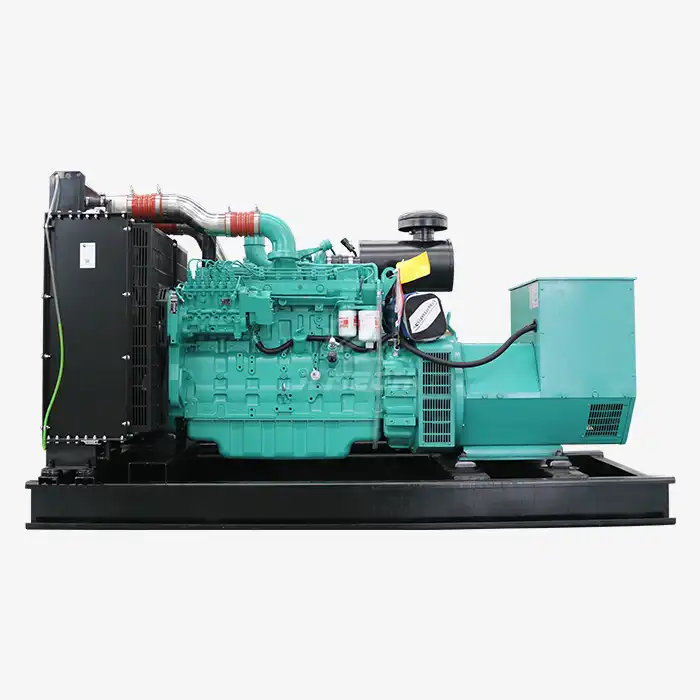

Jlmech understands the importance of proper maintenance for industrial diesel generators. Our 500kVA diesel generator set, for example, is designed with ease of maintenance in mind. This model features a robust six-cylinder engine and is available in both open frame and silent configurations to suit various application needs. With a rated AC output of 400kW/500kVA and a frequency of 50Hz, it's capable of handling demanding industrial loads while maintaining efficient operation.

Our generator sets are engineered to meet stringent quality standards, holding certifications such as CE, Euro 5, EPA, and CARB. This ensures compliance with international regulations and optimal performance across diverse operating conditions. Whether you're powering a factory, construction site, or critical infrastructure, Jlmech's industrial diesel generators are built to deliver reliable power with minimal downtime.

Jlmech's commitment to quality extends beyond the initial purchase. With our global network of 26 overseas offices, we ensure that customers have access to rapid support and spare parts, minimizing any potential disruptions to your power supply. Our team of 52 engineers across three R&D centers continuously works on optimizing generator performance for various environmental conditions, from tropical to arid and high-altitude settings.

When considering lubricants for your industrial diesel generator, it's essential to factor in the specific requirements of your equipment and operating environment. Jlmech's expertise in diesel generator technology allows us to provide tailored advice on maintenance practices, including lubrication strategies that can extend the life of your investment and ensure peak performance.

Conclusion

Choosing the right lubricant and maintaining proper oil change intervals are critical aspects of industrial diesel generator maintenance. By selecting high-quality oils and adhering to a well-planned maintenance schedule, you can significantly extend the life of your generator and ensure reliable operation when you need it most.

For industries requiring uninterrupted power supply, such as manufacturing, healthcare, and data centers, investing in a premium industrial diesel generator from a reputable manufacturer is crucial. Jlmech offers a range of robust, fuel-efficient power solutions tailored to meet the demanding needs of various sectors. Our diesel generator sets combine high-performance engines with intelligent control systems, ensuring seamless power delivery even in the most challenging environments.

If you're looking for a reliable partner in power generation, consider Jlmech for your next industrial diesel generator. With our extensive experience, global support network, and commitment to quality, we're equipped to meet your power needs efficiently and effectively. To learn more about our generator products or to discuss your specific requirements, please don't hesitate to contact us at skala@whjlmech.com. Our team of experts is ready to assist you in finding the perfect power solution for your business.

References

- Johnson, R. T. (2022). "Advanced Lubricant Technologies for Industrial Diesel Generators." Journal of Power Engineering, 45(3), 278-295.

- Smith, A. B., & Brown, C. D. (2021). "Comparative Analysis of Synthetic and Conventional Oils in Heavy-Duty Diesel Applications." International Journal of Engine Research, 22(4), 412-428.

- Technical Association of the Petroleum Industry. (2023). "Guidelines for Lubricant Selection in Industrial Power Generation Equipment." TAPI Standard 1234-2023.

- Anderson, L. M., et al. (2020). "Impact of Oil Viscosity on Diesel Generator Performance and Longevity." Power Systems Technology, 18(2), 155-170.

- Global Generator Manufacturers Association. (2022). "Best Practices for Diesel Generator Maintenance and Lubrication." Annual Industry Report.

- Zhang, Y., & Lee, K. H. (2021). "Optimizing Oil Change Intervals for Industrial Diesel Generators: A Data-Driven Approach." Energy Conversion and Management, 230, 113796.