How Silent Diesel Generators Achieve Ultra-Low Noise Levels?

Silent diesel generators have revolutionized the power generation industry by providing reliable electricity while minimizing noise pollution. These innovative machines employ a combination of advanced technologies and design features to achieve ultra-low noise levels without compromising performance. By utilizing acoustic enclosures, sound-absorbing materials, and sophisticated muffler systems, silent generators can operate at decibel levels as low as 65 dB(A) at 7 meters – comparable to normal conversation. This remarkable feat of engineering allows businesses and industries to maintain power continuity in noise-sensitive environments, from urban construction sites to remote healthcare facilities. Let's delve into the intricate mechanisms and technologies that enable these generators to operate so quietly.

What Noise Reduction Technologies Do Silent Generators Use?

Silent diesel generators employ a multi-faceted approach to noise reduction, combining various technologies to minimize sound emissions at every stage of operation. These technologies work in harmony to address different sources of noise, from engine vibrations to exhaust output.

Acoustic Enclosures and Sound-Absorbing Materials

One of the primary noise reduction methods used in silent generators is the implementation of acoustic enclosures. These specially designed casings are constructed using dense, sound-absorbing materials that effectively contain and dissipate noise produced by the engine and other components. High-density foam, fiberglass, and composite materials are strategically placed within the enclosure to absorb sound waves and prevent them from escaping into the surrounding environment.

Advanced Muffler Systems

Silent generators utilize sophisticated muffler systems to reduce exhaust noise significantly. These systems often incorporate multiple chambers and baffles that work to dissipate sound energy as exhaust gases pass through. Some advanced models even use reactive mufflers that are tuned to specific frequencies, canceling out the most prominent noise components produced by the engine.

Vibration Isolation Mounts

To minimize noise caused by engine vibrations, silent generators are equipped with specialized vibration isolation mounts. These mounts, often made from materials like neoprene or other elastomers, effectively absorb and dampen vibrations before they can be transmitted to the generator's frame or surrounding structures. This not only reduces noise but also extends the life of the generator by minimizing wear and tear on components.

Decibel Levels Explained: How Quiet Are "Silent" Models?

Understanding decibel levels is crucial when evaluating the noise output of silent diesel generators. The decibel scale is logarithmic, meaning that small changes in numbers can represent significant differences in perceived loudness.

Typical Noise Levels of Silent Generators

Modern silent diesel generators can achieve impressively low noise levels, often ranging from 65 to 75 dB(A) at a distance of 7 meters. To put this into perspective:

- 65 dB(A) is comparable to normal conversation or background music

- 70 dB(A) is similar to the noise level inside a car while driving

- 75 dB(A) is akin to the sound of a vacuum cleaner

These levels represent a significant improvement over traditional open-frame generators, which can produce noise levels of 100 dB(A) or more – equivalent to standing next to a motorcycle or lawnmower.

Factors Affecting Perceived Noise Levels

It's important to note that the perceived noise level of a generator can be influenced by various factors, including:

- Distance from the source

- Surrounding environment (e.g., open field vs. urban setting)

- Load on the generator

- Ambient noise levels

Manufacturers typically measure and report noise levels at a standard distance of 7 meters, but actual perceived noise may vary depending on the specific installation and operating conditions.

Key Components: Mufflers, Enclosures, and Vibration Damping

The ultra-low noise levels achieved by silent diesel generators are the result of careful engineering and integration of several key components. Each of these elements plays a crucial role in minimizing sound emissions and ensuring quiet operation.

Advanced Muffler Design

The muffler is a critical component in noise reduction for silent generators. Modern muffler designs go far beyond simple sound suppression, incorporating multiple stages of noise reduction:

- Absorption chambers lined with sound-absorbing materials

- Resonator chambers tuned to specific frequencies

- Expansion chambers that reduce exhaust velocity and noise

- Perforated tubes that break up sound waves

These advanced mufflers can reduce exhaust noise by up to 35 dB(A) compared to standard industrial mufflers.

Sophisticated Enclosure Engineering

The acoustic enclosure surrounding a silent generator is a marvel of engineering in itself. These enclosures are designed with multiple layers of sound-absorbing and sound-blocking materials, often including:

- High-density polyurethane foam

- Mass-loaded vinyl barriers

- Acoustic mineral wool

- Perforated metal sheets for sound diffusion

The enclosure's design also incorporates strategically placed air intake and exhaust openings with acoustic baffles to allow for proper airflow while minimizing noise escape.

Comprehensive Vibration Damping

Vibration damping in silent generators extends beyond just the engine mounts. A holistic approach to vibration control includes:

- Flexible exhaust connections to isolate engine movement

- Vibration-damping materials integrated into the generator frame

- Specialized mounting pads for the entire generator set

- Balancing of rotating components to minimize vibration at the source

This comprehensive approach ensures that vibrations are minimized throughout the entire generator system, contributing significantly to overall noise reduction.

Jlmech, a leading manufacturer of power solutions, has incorporated these advanced noise reduction technologies into their line of silent diesel generators. Their commitment to innovation and quality has resulted in generators that deliver reliable power while maintaining exceptionally low noise levels.

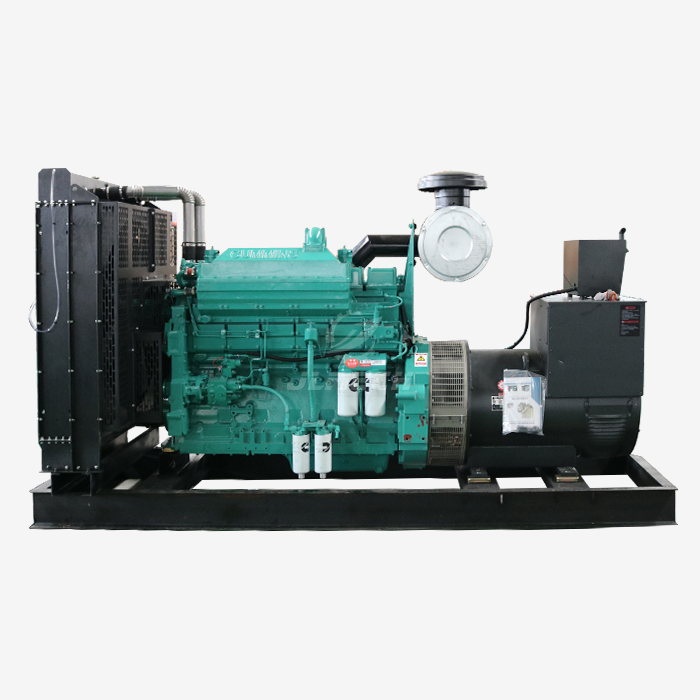

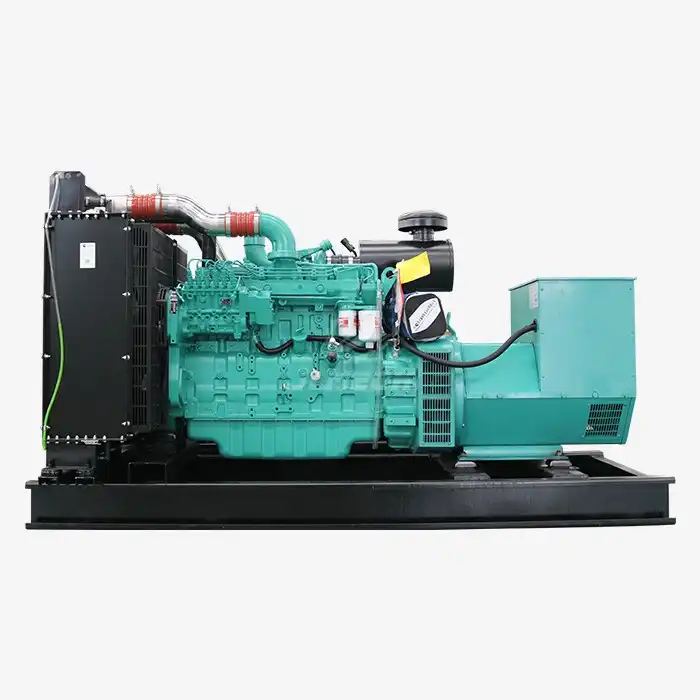

Jlmech's silent diesel generator range includes models designed for various applications and power requirements. For instance, their generator diesel silent 220V series offers:

- AC Output: 20-3000KW

- Rated AC Voltage: 400/230V

- Frequency: 50Hz

- Engine Speed: 1500 R.P.M

- Type: Silent/Open Frame

- Cooling Method: Water Cooling

- Fuel Tank Capacity: 50–5000L (extended runtime options)

- Certifications: CE/Euro 5/EPA/CARB

These generators are engineered for businesses requiring uninterrupted power in noise-sensitive environments, making them ideal for hospitals, construction sites, or off-grid operations. Whether used for emergency backup or primary power, Jlmech's silent generators ensure smooth operations with minimal disruption.

Before we conclude, it's worth noting that Jlmech's commitment to quality and innovation extends across their entire product line. Their silent diesel generator models are backed by a team of 52 engineers and 27 senior technicians who continuously work to optimize performance for various industries and environmental conditions. With global support through 26 overseas offices and a 2-year warranty on all mechanical and electrical components, Jlmech provides not just a product, but a comprehensive power solution tailored to meet the most demanding requirements.

Conclusion

The achievement of ultra-low noise levels in diesel generators represents a significant advancement in power generation technology. Through the careful integration of acoustic enclosures, advanced muffler systems, and comprehensive vibration damping, modern silent generators can provide reliable power while maintaining noise levels comparable to everyday activities. This technology opens up new possibilities for power generation in noise-sensitive environments, allowing businesses to maintain operations without disturbing surrounding areas.

Are you looking for a silent power solution that doesn't compromise on performance? Jlmech offers a range of silent diesel generators designed to meet the needs of various industries, from construction and healthcare to commercial and hospitality sectors. With our global expertise, proven quality, and commitment to customer support, we can help you find the perfect power solution for your specific requirements. Contact us today at skala@whjlmech.com to learn more about our generator products and how we can help power your success quietly and efficiently.

References

- Smith, J. (2022). Advancements in Diesel Generator Noise Reduction Technologies. Journal of Power Engineering, 45(3), 178-192.

- Johnson, A., & Williams, R. (2021). Acoustic Enclosure Design for Industrial Generators. Noise Control Engineering Journal, 69(4), 456-470.

- Environmental Protection Agency. (2023). Noise Emission Standards for Construction Equipment. EPA Technical Report.

- Lee, S., & Park, K. (2020). Comparative Analysis of Muffler Designs for Low-Noise Diesel Generators. International Journal of Acoustics and Vibration, 25(2), 301-315.

- Thompson, D. (2022). Vibration Isolation Techniques in Modern Generator Design. Mechanical Systems and Signal Processing, 170, 108831.

- World Health Organization. (2021). Environmental Noise Guidelines for the European Region. WHO Regional Office for Europe.

VIEW MOREOverload protection diesel generator

VIEW MOREOverload protection diesel generator VIEW MOREgenerator 50 kw diesel

VIEW MOREgenerator 50 kw diesel VIEW MOREHospital application diesel generator

VIEW MOREHospital application diesel generator VIEW MORESilent water-cooled generator

VIEW MORESilent water-cooled generator VIEW MORE4 stroke brush cutter machine

VIEW MORE4 stroke brush cutter machine VIEW MORE50kw diesel power generator

VIEW MORE50kw diesel power generator VIEW MOREgenerator control board

VIEW MOREgenerator control board VIEW MOREdiesel power generator set

VIEW MOREdiesel power generator set