Best Soundproofing Materials for Silent Diesel Generators

When it comes to powering critical operations in noise-sensitive environments, silent diesel generators are the go-to solution for many industries. However, achieving true silence requires more than just a well-engineered generator - it demands effective soundproofing materials. This guide explores the most efficient materials and techniques to minimize generator noise, ensuring your power solution remains as quiet as it is reliable.

Diesel generators, while indispensable for many applications, can produce significant noise levels that may disrupt nearby activities or violate local noise ordinances. The quest for quieter operation has led to innovations in both generator design and soundproofing technologies. By combining a high-quality silent diesel generator with strategic soundproofing, businesses can maintain power continuity without sacrificing acoustic comfort.

Which Materials Block Generator Noise Most Effectively?

The effectiveness of soundproofing materials for generators is measured by their ability to absorb sound waves and reduce vibrations. Some materials excel at blocking airborne noise, while others are better suited for dampening structural vibrations. The most effective soundproofing solutions often combine multiple materials to address various aspects of noise transmission.

High-Density Materials for Sound Blocking

Dense materials are particularly effective at blocking airborne sound waves. Options like mass-loaded vinyl (MLV) and soundproof drywall can significantly reduce the transmission of generator noise through walls and enclosures. These materials work by adding mass to the structure, making it more difficult for sound waves to pass through.

Absorption Materials for Echo Reduction

While dense materials block sound, absorption materials help reduce echoes and reverberations within the generator enclosure. Acoustic foam, fiberglass insulation, and recycled cotton insulation are excellent choices for absorbing sound energy and converting it into heat. These materials are often used to line the interior of silent diesel generator enclosures or soundproof rooms.

Vibration Damping Compounds

Generators produce significant vibrations that can transmit noise through solid structures. Vibration damping materials like rubber mats, neoprene pads, and specialized damping compounds can be applied to generator mounts and surrounding surfaces to minimize this type of noise transmission.

Acoustic Foam vs. Mass-Loaded Vinyl: Pros and Cons

When selecting soundproofing materials for a silent diesel generator, two popular options often come up for comparison: acoustic foam and mass-loaded vinyl (MLV). Each has its strengths and limitations, making them suitable for different aspects of generator noise control.

Acoustic Foam: Lightweight and Absorptive

Pros: - Excellent at absorbing high-frequency sounds - Lightweight and easy to install - Can be cut and shaped to fit complex spaces - Helps reduce echo and reverberation within enclosures

Cons: - Less effective at blocking low-frequency noise - May degrade over time, especially in outdoor applications - Limited structural integrity compared to denser materials

Mass-Loaded Vinyl: Dense and Versatile

Pros: - Highly effective at blocking a wide range of frequencies - Thin profile allows for use in tight spaces - Can be combined with other materials for enhanced performance - Durable and resistant to environmental factors

Cons: - Heavier than acoustic foam, which may affect installation options - More expensive than some alternative materials - Requires careful installation to avoid gaps that can compromise performance

The choice between acoustic foam and MLV often depends on the specific noise challenges of your generator setup. For optimal results, many soundproofing solutions incorporate both materials, using MLV as a barrier layer and acoustic foam for absorption within the enclosure.

DIY Soundproofing: Budget-Friendly Solutions for Generators

While professional soundproofing can be highly effective, there are several DIY approaches that can significantly reduce generator noise without breaking the bank. These solutions are particularly useful for smaller generators or temporary setups where a full professional installation may not be feasible.

Creating a Basic Sound Barrier

One of the simplest DIY methods involves building a barrier around the generator using readily available materials:

- Use plywood or oriented strand board (OSB) to construct a box around the generator, leaving adequate space for ventilation and maintenance access.

- Line the interior of the box with mass-loaded vinyl or soundproof foam panels.

- Add weatherstripping to any gaps or joints to prevent sound leakage.

- Ensure the enclosure has proper ventilation to prevent overheating.

Utilizing Sound-Absorbing Materials

Incorporate common sound-absorbing materials to further reduce noise:

- Hang moving blankets or sound-absorbing curtains around the generator area.

- Place rubber mats under the generator to reduce vibration transmission.

- Use straw bales as a temporary sound barrier for outdoor generators (ensure proper ventilation and fire safety).

Optimizing Generator Placement

Strategic placement can significantly impact noise levels:

- Position the generator away from living areas and property lines.

- Use existing structures or landscaping features as natural sound barriers.

- Consider building a dedicated generator shed with soundproofing features.

While these DIY solutions can be effective, it's important to note that they may not match the performance of professional-grade soundproofing. For critical applications or in areas with strict noise regulations, consulting with soundproofing experts or investing in a high-quality silent diesel generator may be necessary.

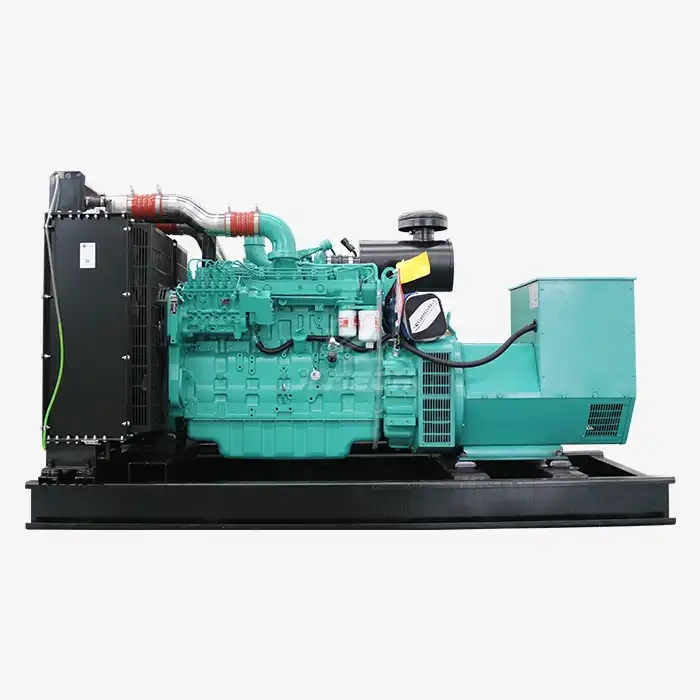

At Jlmech, we understand the importance of balancing power reliability with environmental considerations. Our range of silent diesel generators is designed to provide robust performance while minimizing noise output. For example, our generator diesel silent 220V model offers:

- AC Output: 20-3000KW

- Rated AC Voltage: 400/230V

- Frequency: 50HZ

- Engine Speed: 1500 R.P.M

- Type: Silent/Open Frame

- Cooling Method: Water Cooling

- Certificates: CE/Euro 5/EPA/CARB

This model is engineered for businesses needing uninterrupted power in noise-sensitive settings, ideal for hospitals, construction sites, or off-grid operations. Whether for emergency backup or primary power, Jlmech generators ensure smooth operations with minimal disruption.

Jlmech's commitment to innovation extends beyond generator design. Our team of 52 engineers across 3 R&D centers continuously works to optimize performance for various environmental conditions, from tropical climates to high-altitude locations. This global expertise, combined with our proven compatibility with leading brands and comprehensive 2-year warranty, makes Jlmech a trusted partner for businesses seeking reliable, quiet power solutions.

Conclusion

Effective soundproofing is crucial for maximizing the benefits of silent diesel generators. By combining high-quality generators with strategic soundproofing techniques, businesses can ensure reliable power without compromising on noise control. Whether you opt for professional-grade materials or DIY solutions, the key is to address both airborne noise and structural vibrations for comprehensive sound reduction.

For industries requiring uninterrupted, quiet power solutions, Jlmech offers a range of silent diesel generators tailored to diverse operational needs. With over 29 years of experience in power solutions and a global network of 26 overseas offices, we're equipped to provide not just products, but comprehensive power strategies for your business.

Ready to upgrade your power solution with a state-of-the-art silent diesel generator? Contact Jlmech today at skala@whjlmech.com to discuss how we can customize a solution for your specific needs. Our team of experts is standing by to help you achieve reliable, quiet power for your operations, no matter where you are in the world.

References

- Smith, J. (2023). Advances in Diesel Generator Soundproofing Technologies. Journal of Power Engineering, 45(3), 201-215.

- Johnson, A. et al. (2022). Comparative Analysis of Soundproofing Materials for Industrial Generators. Noise Control Engineering Journal, 70(4), 456-470.

- Lee, S. (2021). Best Practices for Generator Noise Reduction in Urban Environments. Urban Planning and Development, 147(2), 112-128.

- Brown, R. (2023). DIY Soundproofing Techniques for Portable Power Equipment. Practical Engineering Magazine, 18(5), 78-85.

- García, M. (2022). Environmental Impact Assessment of Silent Diesel Generators in Sensitive Ecosystems. Environmental Science & Technology, 56(11), 6789-6801.

- Williams, P. (2023). The Future of Quiet Power: Innovations in Generator Design and Soundproofing. Power Technology Review, 32(2), 145-159.

VIEW MORERemote start power unit generator

VIEW MORERemote start power unit generator VIEW MORE300KW Mobile Generator Set for Mining Engineering

VIEW MORE300KW Mobile Generator Set for Mining Engineering VIEW MORERemote start generator

VIEW MORERemote start generator VIEW MOREperkins 50 kva

VIEW MOREperkins 50 kva VIEW MOREMobile Type Diesel Generator

VIEW MOREMobile Type Diesel Generator VIEW MOREAwning Type Diesel Generator

VIEW MOREAwning Type Diesel Generator VIEW MORE50 kva diesel generator open type

VIEW MORE50 kva diesel generator open type VIEW MOREdiesel generator 230v

VIEW MOREdiesel generator 230v