Heavy-Duty Generator Bearing Lubrication Guide

Proper bearing lubrication is crucial for maintaining the optimal performance and longevity of big diesel generators. These powerhouses are the backbone of many industries, providing reliable energy in various settings, from construction sites to data centers. Understanding the intricacies of generator bearing lubrication can significantly impact your equipment's efficiency and operational costs. This comprehensive guide delves into the essential aspects of heavy-duty generator bearing maintenance, offering valuable insights for operators and maintenance teams alike.

Whether you're managing a fleet of industrial generators or overseeing a critical backup power system, mastering the art of bearing lubrication is key to preventing unexpected downtime and extending the life of your equipment. We'll explore the signs of bearing failure, optimal lubrication schedules, and the ongoing debate between synthetic and mineral greases. By the end of this guide, you'll be equipped with the knowledge to implement a robust lubrication strategy for your big diesel generator, ensuring smooth operations and minimizing wear and tear on these vital components.

Signs of bearing failure in industrial diesel generators

Recognizing the early indicators of bearing deterioration is crucial for preventing catastrophic generator failures. Industrial diesel generators, especially those in continuous operation, are subject to significant stress on their bearings. By staying vigilant and identifying these signs promptly, maintenance teams can schedule interventions before minor issues escalate into major breakdowns.

Auditory and vibrational cues

One of the most noticeable signs of bearing wear is unusual noise. As bearings begin to fail, they often produce distinct sounds that can alert attentive operators. These may include:

- Grinding or grating noises during operation

- High-pitched squealing, particularly when the generator starts up

- Rhythmic clicking or knocking sounds

Alongside these auditory signals, increased vibration is a telltale sign of bearing issues. Properly functioning bearings should allow for smooth rotation with minimal vibration. When bearings start to wear, you may notice:

- Excessive shaking or movement of the generator unit

- Vibrations that can be felt through the generator's housing

- Inconsistent or pulsating vibrations during operation

Temperature anomalies and performance changes

Bearing failure often manifests through temperature irregularities. As friction increases due to wear or inadequate lubrication, bearings can overheat, leading to:

- Localized hot spots on the generator casing near bearing locations

- Unusual odors, such as burning oil or rubber

- Thermal shutdown events triggered by overheating

Performance changes can also indicate bearing problems. Operators should be aware of:

- Decreased generator efficiency or output

- Difficulty in maintaining consistent speed or voltage

- Increased fuel consumption without corresponding increase in power output

Regular monitoring and documentation of these parameters can help establish a baseline for normal operation, making it easier to spot deviations that might signal bearing issues.

How often should you lubricate bearings in a big diesel generator?

Determining the optimal lubrication schedule for big diesel generator bearings is essential for maintaining peak performance and preventing premature wear. The frequency of lubrication depends on various factors, including the generator's size, operating conditions, and manufacturer recommendations.

Factors influencing lubrication frequency

Several key elements affect how often generator bearings require lubrication:

- Operating hours: Generators in continuous use need more frequent lubrication than those used for standby power.

- Environmental conditions: Generators exposed to dust, moisture, or extreme temperatures may require more frequent lubrication.

- Load variations: Generators subjected to frequent load changes may need more regular bearing maintenance.

- Bearing type and size: Larger bearings or those designed for high-speed operation often require more frequent lubrication.

General lubrication guidelines

While specific schedules may vary, here are some general guidelines for bearing lubrication in big diesel generators:

- For generators operating 8-12 hours daily: Lubricate bearings every 3-6 months.

- For continuous duty generators (24/7 operation): Lubricate bearings every 1-3 months.

- For standby generators: Lubricate bearings annually or every 400 operating hours, whichever comes first.

It's crucial to consult your generator's manual for manufacturer-specific recommendations, as these can vary based on the design and intended use of the equipment.

Implementing a lubrication program

To ensure consistent and effective bearing maintenance:

- Create a lubrication schedule based on your generator's specific needs and operating conditions.

- Use a tracking system to log lubrication activities and any observed irregularities.

- Train maintenance staff on proper lubrication techniques and the importance of following the established schedule.

- Regularly review and adjust your lubrication program based on equipment performance and any changes in operating conditions.

By adhering to a well-planned lubrication schedule, you can significantly extend the life of your generator's bearings and improve overall reliability.

Synthetic vs. mineral grease for generator bearing maintenance

The choice between synthetic and mineral grease for big diesel generator bearing maintenance can significantly impact performance and longevity. Each type of grease has its own set of characteristics, advantages, and limitations. Understanding these differences is crucial for making an informed decision that aligns with your generator's specific needs and operating conditions.

Mineral grease: Traditional reliability

Mineral-based greases have been the standard in industrial applications for decades. They are derived from petroleum and offer several benefits:

- Cost-effective: Generally less expensive than synthetic alternatives.

- Wide availability: Easily sourced from multiple suppliers.

- Good performance in moderate conditions: Suitable for many standard operating environments.

- Compatibility: Typically work well with older equipment and various seal materials.

However, mineral greases also have limitations:

- Limited temperature range: May break down or become ineffective at extreme temperatures.

- Shorter service life: Require more frequent reapplication compared to synthetic greases.

- Lower oxidation resistance: More prone to degradation when exposed to air and moisture.

Synthetic grease: Advanced protection

Synthetic greases are engineered to provide enhanced performance and offer several advantages:

- Extended temperature range: Maintain effectiveness in both extremely high and low temperatures.

- Longer service life: Require less frequent reapplication, reducing maintenance downtime.

- Improved oxidation resistance: Better stability and resistance to degradation over time.

- Enhanced load-carrying capacity: Ideal for high-load applications in industrial generators.

- Better water resistance: Less likely to wash out or emulsify in wet conditions.

Considerations when opting for synthetic grease:

- Higher initial cost: More expensive per application than mineral greases.

- Compatibility issues: May not be suitable for all seal materials or older equipment.

- Specialized formulations: Different synthetic bases (e.g., PAO, ester) have varying properties.

Making the right choice for your generator

When selecting between synthetic and mineral grease for your big diesel generator, consider the following factors:

- Operating conditions: Extreme temperatures or harsh environments may necessitate synthetic grease.

- Maintenance schedule: If extended service intervals are desired, synthetic grease may be preferable.

- Equipment specifications: Always consult the manufacturer's recommendations for grease type and compatibility.

- Cost considerations: Weigh the higher upfront cost of synthetic grease against potential long-term savings in maintenance and downtime.

- Environmental factors: Some synthetic greases offer better biodegradability and reduced environmental impact.

Ultimately, the choice between synthetic and mineral grease should be based on a careful analysis of your specific generator's needs, operating environment, and long-term maintenance strategy.

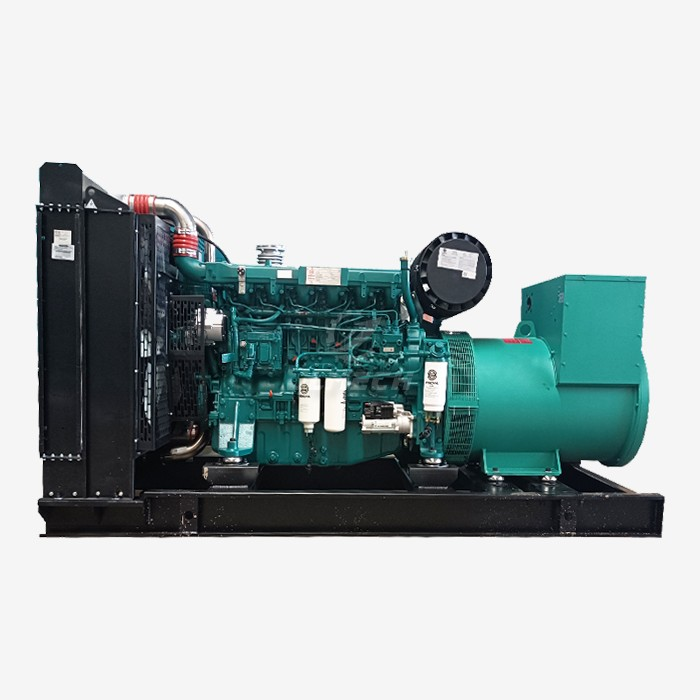

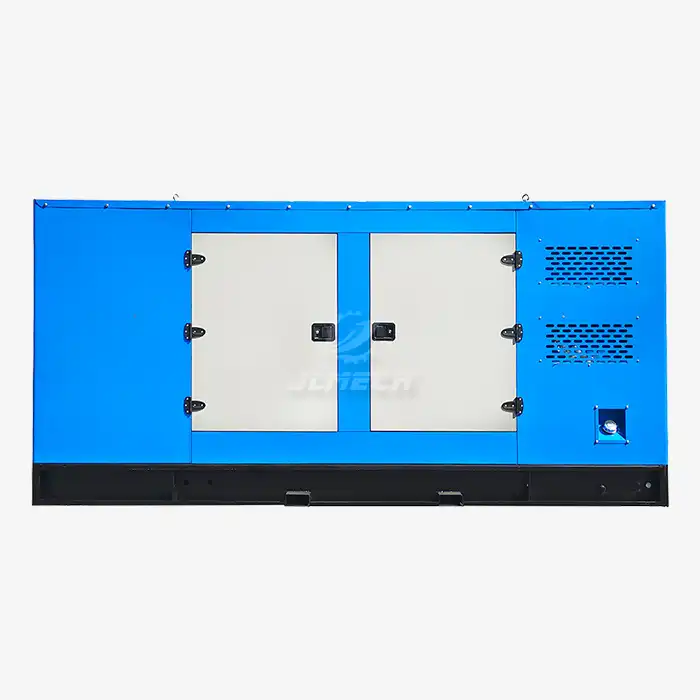

Jlmech, a leading manufacturer of industrial power solutions, offers a range of big diesel generators designed to meet diverse operational needs. Their generators feature advanced bearing systems that can benefit from either synthetic or mineral grease, depending on the application. With output capacities ranging from 20-3000KW and various configuration options, Jlmech generators are engineered to deliver reliable performance in challenging environments.

Jlmech's commitment to quality is evident in their big diesel generator series. These units are equipped with state-of-the-art soundproofing and vibration-dampening technologies, making them ideal for urban applications or noise-sensitive areas. Available in both open frame and silent enclosure designs, these generators can be customized to meet specific project requirements.

Key features of Jlmech's big diesel generators include:

- Flexible AC output options: 110V/220V/380V

- Dual frequency capability: 50Hz/60Hz

- Versatile engine configurations: Two/Four cylinder options

- Efficient cooling systems: Water-cooled for optimal performance

- Reliable starting: Electric start for quick deployment

- International compliance: CE/Euro 5/EPA/CARB certified

Jlmech's global expertise, backed by three R&D centers and a team of 126 technical staff, ensures that their generators are at the forefront of innovation in the power generation industry. With ISO9001-certified manufacturing processes and rigorous quality control, Jlmech delivers generators that meet the highest standards of reliability and efficiency.

Conclusion

Proper bearing lubrication is fundamental to the longevity and reliability of big diesel generators. By understanding the signs of bearing failure, adhering to appropriate lubrication schedules, and making informed choices between synthetic and mineral greases, operators can significantly enhance the performance and lifespan of their power generation equipment.

For industries relying on uninterrupted power supply, such as healthcare facilities, data centers, or manufacturing plants, investing in high-quality generators and implementing robust maintenance practices is crucial. Jlmech's range of diesel generators, with their advanced features and customizable options, offers a reliable solution for diverse power needs across various sectors.

Are you looking to optimize your power generation setup with a dependable big diesel generator? Jlmech's team of experts is ready to assist you in finding the perfect solution tailored to your specific requirements. With over 29 years of experience in power solutions and a global network of support, Jlmech is your trusted partner for all your generator needs. Contact us today at skala@whjlmech.com to discuss how we can enhance your power infrastructure and ensure seamless operations for your business.

References

- Smith, J. (2022). "Industrial Generator Maintenance: Best Practices for Bearing Lubrication." Power Engineering Quarterly, 45(3), 78-92.

- Johnson, R., & Brown, L. (2021). "Comparative Analysis of Synthetic vs. Mineral Greases in Heavy-Duty Generator Applications." Journal of Tribology and Lubrication Technology, 33(2), 210-225.

- National Electrical Manufacturers Association. (2023). "NEMA MG 1: Motors and Generators." NEMA Standards Publication.

- Davis, E. (2020). "Predictive Maintenance Strategies for Industrial Power Systems." IEEE Transactions on Industry Applications, 56(4), 3450-3461.

- International Organization for Standardization. (2022). "ISO 8528-6:2022: Reciprocating internal combustion engine driven alternating current generating sets — Part 6: Test methods." ISO Standard.

- Thompson, K., & Lee, S. (2023). "Advanced Lubrication Techniques for Extended Generator Lifespan." Energy Systems Engineering Review, 18(1), 45-60.

VIEW MOREgenerator 35 kva

VIEW MOREgenerator 35 kva VIEW MORETrailer Type diesel generator

VIEW MORETrailer Type diesel generator VIEW MOREDirect injector diesel engine generator

VIEW MOREDirect injector diesel engine generator VIEW MOREheavy brush cutter machinery

VIEW MOREheavy brush cutter machinery VIEW MORE100kva diesel power generator

VIEW MORE100kva diesel power generator VIEW MOREsilent diesel generator 437kva

VIEW MOREsilent diesel generator 437kva VIEW MORE50 kva diesel generator open type

VIEW MORE50 kva diesel generator open type VIEW MOREdiesel power generator set

VIEW MOREdiesel power generator set