Why is my diesel engine not reaching full RPM?

A diesel generator's RPM (Revolutions Per Minute) is precisely set to maintain the correct electrical output frequency—typically 1800 RPM for 60 Hz or 1500 RPM for 50 Hz power. When your generator cannot achieve its rated speed, it fails to deliver stable voltage and frequency, potentially damaging connected equipment. A low rpm diesel generator often indicates an underlying issue that requires immediate attention to avoid more severe damage or operational failure.

Common Causes of Low RPM in Diesel Generators

Identifying the root cause is essential for effective troubleshooting. The most frequent reasons a generator may not reach full RPM include:

Fuel System Issues:

- Clogged fuel filters restricting flow to the engine

- Air trapped in the fuel lines, disrupting injection

- A faulty fuel lift pump not delivering adequate pressure

- Contaminated fuel or water in the fuel tank

Air Intake Problems:

- A dirty or blocked air filter reducing oxygen supply

- Leaks or restrictions in the intake piping

- Turbocharger issues (if equipped), such as stuck vanes or boost pressure loss

Mechanical Faults:

- Overloading: Electrical demand exceeding the generator’s capacity

- A malfunctioning governor unable to regulate engine speed

- Worn or faulty fuel injectors disrupting combustion

Control and Sensor Errors:

- Faulty RPM sensors sending incorrect data to the controller

- Incorrect throttle linkage adjustment or electronic throttle failure

A low rpm diesel generator not only performs poorly but also risks damaging the engine and connected devices due to underfrequency operation.

Maintenance Tips to Prevent RPM Issues

Proper maintenance is the most effective way to avoid low RPM problems and ensure reliable operation:

Follow a Regular Service Schedule:

- Change fuel filters, air filters, and oil according to the manufacturer’s recommendations

- Regularly inspect and clean the fuel tank to prevent sediment buildup

Use High-Quality Fuel and Additives:

- Source fuel from reputable suppliers to avoid contamination

- Use fuel stabilizers and biocides if the generator is stored for long periods

Monitor Load Levels:

- Avoid exceeding the generator's rated capacity—use load banks if necessary to test performance

- Balance phases evenly to prevent overloading one section of the generator

Perform Visual and Operational Checks:

- Look for leaks, loose connections, or signs of wear during routine inspections

- Test the generator under load periodically to ensure it reaches and maintains full RPM

- Proactive maintenance helps prevent a low rpm diesel generator scenario, saving time and costly repairs while maximizing uptime.

Conclusion

A diesel generator struggling to reach full RPM requires prompt diagnosis and action. While some issues can be resolved with basic maintenance, others may indicate serious mechanical or electrical faults needing professional repair. Regular servicing and careful operation are your best defenses against low RPM problems.

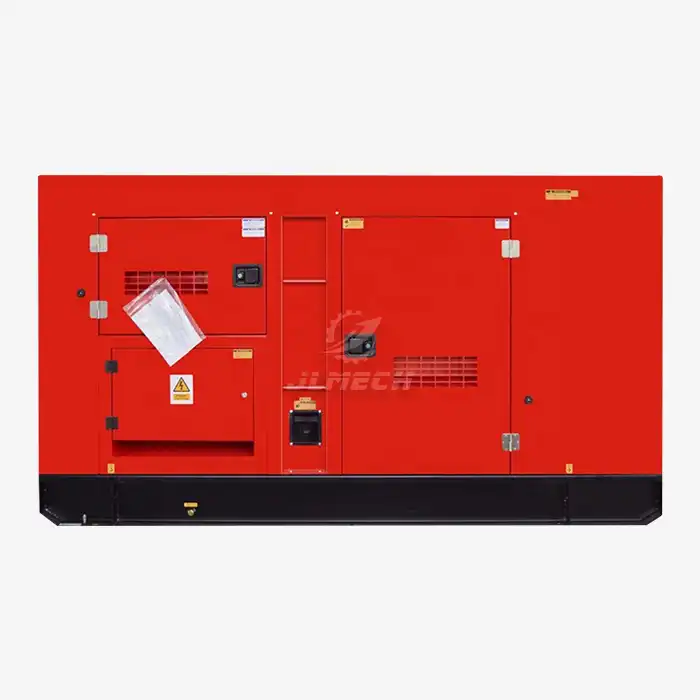

At JLMECH, we combine extensive expertise in power generation with an unwavering commitment to quality and reliability. Our team specializes in diagnosing and resolving generator performance issues, ensuring your equipment operates at peak efficiency.

If you’re experiencing persistent RPM issues, our technical experts can help. Contact us at skala@whjlmech.com for professional support, maintenance services, or to explore our range of high-performance diesel generators.

References

International Organization for Standardization. (2018). *ISO 8528-5: Reciprocating internal combustion engine driven alternating current generating sets – Part 5: Generating sets*.

National Fire Protection Association. (2022). NFPA 110: Standard for Emergency and Standby Power Systems.

Johnson, M. (2022). Emergency Power Systems: A Comprehensive Guide to High-Speed Diesel Generators. Power Engineering Quarterly, 45(3), 78–92.

Peterson, W. R. (2021). Diesel Generator Maintenance: Best Practices for Reliability. Power Engineering Journal, 39(2), 45–58.