What material is best for generator sound absorption?

For businesses and industries relying on diesel generators, ensuring reliable power is paramount. However, the accompanying noise can be a significant challenge, leading to environmental compliance issues, operator fatigue, and community disturbances. Selecting the best sound absorbing material for generator units is not a luxury but a necessity for sustainable and considerate operations. This guide will help you understand the different materials available and how to choose the most effective one for your specific needs, ensuring your operations are both powerful and peaceful.

Understanding Generator Noise

Generator noise is a complex mix of sounds from multiple sources. The engine produces low-frequency rumble from combustion and mechanical movements, the cooling fan creates mid-to-high-frequency whooshing sounds, and the alternator can generate high-frequency whine. This combination of low, medium, and high frequencies is why a single material is rarely the complete solution. Effective noise control requires a strategy that addresses this entire acoustic spectrum. Understanding this breakdown is the first step in choosing the right best sound absorbing material for generator applications.

Sound Absorption vs. Sound Insulation: A Critical Difference

Before selecting materials, it's vital to distinguish between two key principles:

Sound Absorption: These materials are porous and convert sound energy into minimal heat within their structure, reducing echo and reverberation inside an enclosure. They prevent sound waves from bouncing around. Examples include open-cell foam and acoustic polyester fiber.

Sound Insulation: These materials are dense and massive, and they work by blocking sound from transmitting through a barrier, such as an enclosure wall or panel. Their goal is to contain the sound.

A high-performance generator enclosure will almost always combine both types of materials—using absorptive materials on the interior walls to dampen sound and insulated panels to block it from escaping.

Top Material Choices for Effective Control

No single material can claim to be the universal best sound absorbing material for generator noise, as effectiveness depends on the target frequency. However, several materials have proven highly effective in professional applications.

Porous Absorbers (Polyurethane Foam, Melamine Foam): These are excellent for mid and high-frequency noise (typically above 500 Hz). Their open-cell structure allows sound waves to enter, where friction and air movement convert the energy into heat. A 2022 study on a variable-frequency generator set found that polyurethane foam with a density of 35 kg/m³ and a thickness of 10 mm provided the best noise reduction across various loads .

Foamed Aluminum: This innovative material is a hybrid, offering both absorption and insulation properties. Research shows it is highly effective for high-frequency noise, with closed-cell foam performing best above 500 Hz. For low-frequency noise (63-125 Hz), open-cell foamed aluminum is more effective. Its key advantage is that it can be composited with steel panels, dramatically improving low-frequency insulation; a 20mm thick closed-cell foamed aluminum sheet with a 20mm air gap to steel can reduce noise by 10-20 dB.

Fiberglass and Mineral Wool: These are classic, high-performance absorbers used in industrial settings. They are very effective across a broad frequency range but often require careful handling and covering to contain fibers, making them less ideal for all applications.

Composite Barriers: Often, the most effective solution is a multi-layered panel. One study successfully developed an acoustic enclosure using a combination of galvanized metal sheet (0.90 mm), Polyurethane acoustic foam (7.50 mm), and a Particle board (35.0 mm), achieving an average noise reduction of 23.20 dB(A). This approach combines mass, absorption, and damping in a single panel.

The following table summarizes the primary materials and their best-use cases:

| Material Type | Best For Frequency | Key Characteristics |

|---|---|---|

| Polyurethane Foam | Mid to High | Porous, good absorber, often used inside enclosures . |

| Foamed Aluminum | High (Closed-cell), Low (Open-cell) | Rigid, can be composited with panels, good for both absorption and insulation . |

| Fiberglass/Mineral Wool | Broad Range | High performance but may require encapsulation for safety. |

| Mass-Loaded Vinyl (MLV) | All (as a Barrier) | Flexible, high-mass material used to add insulation to walls and panels. |

| Composite Panels | All Frequencies | Combines multiple materials for balanced performance . |

A Step-by-Step Selection Guide

Choosing the right best sound absorbing material for generator noise involves a structured decision-making process.

Identify Your Priority: Determine if your main goal is to protect operators right next to the generator (requiring good absorption inside the enclosure) or to reduce noise for the surrounding community (requiring high insulation in the enclosure walls).

Analyze the Noise Spectrum: If possible, use a sound level meter with frequency analysis. Is the noise a low rumble or a high-pitched whine? This will point you toward low-frequency blockers or high-frequency absorbers.

Consider the Environment: Will the material be exposed to fuel, oil, high temperatures, or moisture? Materials like foamed aluminum and certain treated foams offer better durability in harsh conditions compared to standard acoustic foam.

Evaluate Practical Constraints: Consider factors like weight, thickness, and ease of installation. A dense, heavy composite panel may be highly effective but could be overkill for a small, portable generator.

Plan for a Hybrid Approach: Remember that combining materials yields the best results. Use absorptive materials like foam or fiberglass on the interior surfaces of an enclosure to reduce reverberation, and use dense, insulating materials like mass-loaded vinyl or composite panels for the walls to block sound transmission.

Implement and Test: After installation, measure the noise levels again to verify performance. Minor adjustments, like sealing gaps, can lead to significant improvements.

Case Study: Material Impact

A practical example underscores the importance of material choice. A study on a 2kW household generator showed that without any enclosure, the generator produced an average of 86.23 dB(A). After being placed inside a custom-built enclosure made from a multilayer panel (galvanized metal sheet, polyurethane foam, and particle board), the noise level dropped to an average of 69.34 dB(A)—a reduction of 16.89 dB(A). This demonstrates that a well-designed enclosure using the right combination of materials can dramatically lower noise to safer and more acceptable levels.

Common Mistakes to Avoid

Ignoring Low Frequencies: Simply lining an enclosure with thin foam will do little to address the low-frequency rumble of a diesel engine. You must incorporate mass or resonant absorbers for low-end noise.

Neglecting Ventilation: An enclosure must allow for adequate airflow to prevent overheating. All vents and ducts must be acoustically treated with baffles or liners to prevent them from becoming paths for sound to escape.

Overlooking Gaps and Flanking Paths: Even a small gap in an enclosure can drastically compromise its acoustic performance. Ensure all panels are sealed with acoustic gaskets or sealant.

Conclusion

Selecting the best sound absorbing material for generator applications is a nuanced process that depends on your specific generator model, noise profile, and operational environment. There is no one-size-fits-all answer, but the most effective solutions typically combine porous absorbers for mid and high-frequency noise with dense, massive barriers or specialized composites for low-frequency rumble. By understanding the principles of sound control and the properties of different materials, you can make an informed decision that ensures your power generation is as quiet as it is reliable.

Our expert team can help you choose the most suitable generator. Please send an email to skala@whjlmech.com to learn about our customized products and services designed for your company's unique power needs.

References

- Wu, X. (2022). Application of Sound Absorbing Material in Noise Control of Variable-frequency Generator Set. Science Technology and Industry, 22(6), 277-282.

- Macangus-Gerrard, G. (2018). Environmental Protection. In Offshore Electrical Engineering Manual (Second Edition). Elsevier.

- Wei, L., Liu, H., Tian, Y., & Li, Y. (2015). Study on Sound Insulation Performance of Foam Aluminum Material for Generator Noise. Functional Materials, 14, 14033-14037.

- Udo, O. T. (2017). Noise Level Investigation and Control of Household Electric Power Generator. Research Output.

- European Mechanical Science. (2022). A Review on Noise Suppression in Generators: Comparative Analysis and New Recommendations. European Mechanical Science, 6, 161-178.

VIEW MOREMining diesel generator

VIEW MOREMining diesel generator VIEW MOREBackup diesel generator

VIEW MOREBackup diesel generator VIEW MOREOptionas Remote Control System Silent Diesel Generator

VIEW MOREOptionas Remote Control System Silent Diesel Generator VIEW MORECummins Diesel Engine /Generator

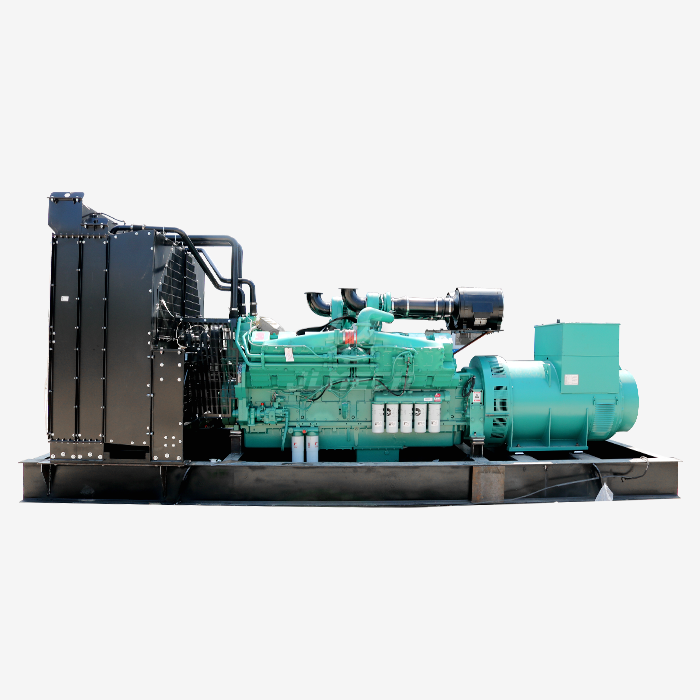

VIEW MORECummins Diesel Engine /Generator VIEW MORE30KW 50Hz 220V diesel generator

VIEW MORE30KW 50Hz 220V diesel generator VIEW MOREVolvopenta diesel generator 100KW

VIEW MOREVolvopenta diesel generator 100KW VIEW MOREcultivators mini tiller rotary

VIEW MOREcultivators mini tiller rotary VIEW MOREelectric powered leaf blower

VIEW MOREelectric powered leaf blower