What is the difference between brushed and brushless generators?

When it comes to diesel generators, one of the key distinctions lies in their alternator design: brushed and brushless. This fundamental difference significantly impacts reliability, efficiency, and maintenance requirements. Brushless generators, increasingly favored in modern power solutions, utilize electromagnetic induction to produce electricity without physical contact between rotating components. In contrast, brushed generators rely on carbon brushes making direct contact with a commutator to transfer electrical current. The brushless design eliminates wear-prone components, resulting in reduced maintenance needs and enhanced longevity. For industries requiring uninterrupted power supply, such as data centers or healthcare facilities, the reliability of brushless generators often makes them the preferred choice. However, both types have their merits depending on specific applications and operational contexts. Understanding these differences is crucial for businesses and organizations looking to invest in robust power generation solutions that align with their unique needs and operational demands.

Brushed vs. Brushless Diesel Generators: Which Is More Reliable & Efficient?

Reliability and efficiency are paramount considerations when selecting a diesel generator for your power needs. Brushless generators typically edge out their brushed counterparts in both these critical areas.

Reliability Comparison

Brushless generators excel in reliability due to their simpler design and fewer wear-prone components. Without brushes and slip rings, there's less mechanical friction and fewer parts that can fail. This design leads to:

- Reduced downtime for maintenance

- Lower risk of unexpected failures

- Consistent performance over time

Brushed generators, while still reliable, require more frequent maintenance to replace worn brushes and address potential commutator issues. This can lead to increased downtime and higher long-term operational costs.

Efficiency Analysis

When it comes to efficiency, brushless generators generally have the upper hand:

- Higher power output relative to size

- Better fuel efficiency, particularly under varying loads

- Improved heat dissipation, leading to cooler operation

Brushed generators can be efficient, especially in smaller sizes or specific applications. However, the friction inherent in their design can lead to energy losses, particularly as the generator ages and brushes wear down.

For industries like manufacturing or healthcare, where consistent, efficient power is crucial, brushless generators often provide superior performance. Jlmech, a leader in power solutions, offers advanced brushless generator designs that maximize both reliability and efficiency for demanding industrial applications.

Why Choose a Brushless Generator? Lower Maintenance & Longer Lifespan Explained

The appeal of brushless generators extends beyond their initial performance advantages. Their design characteristics contribute significantly to reduced maintenance requirements and an extended operational lifespan.

Maintenance Advantages of Brushless Generators

Brushless generators require substantially less maintenance compared to their brushed counterparts:

- No brush replacement: Eliminating the need for periodic brush changes saves time and reduces maintenance costs.

- Reduced wear on components: With fewer moving parts, there's less mechanical stress and wear over time.

- Less frequent servicing: Longer intervals between maintenance checks mean less downtime and lower labor costs.

For industries like construction or remote mining operations, where equipment reliability is crucial and maintenance access may be limited, these factors can translate into significant operational benefits and cost savings.

Longevity and Durability

The simpler design of brushless generators contributes to their extended lifespan:

- Reduced heat generation: Less friction means cooler operation, which prolongs component life.

- Resistance to environmental factors: Sealed designs protect internal components from dust, moisture, and other contaminants.

- Consistent performance over time: Without brush wear, output remains stable throughout the generator's life.

These factors make brushless generators particularly suitable for applications requiring long-term reliability, such as backup power systems for data centers or continuous power supply in industrial settings.

Diesel generator users in sectors like agriculture or rural electrification benefit from the reduced need for technical expertise and the ability to operate equipment for extended periods with minimal intervention. This reliability is especially valuable in remote or underserved areas where immediate technical support may not be readily available.

How Does a Brushless Diesel Generator Work?

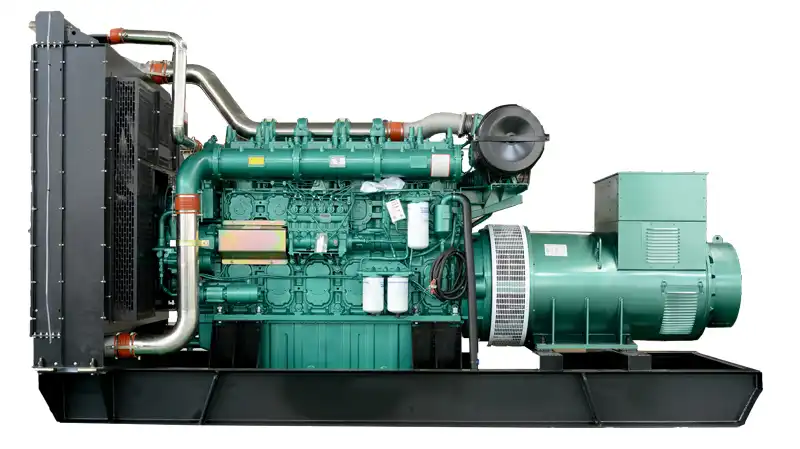

A brushless diesel generator operates by generating electrical power through the mechanical energy produced by a diesel engine. Unlike traditional generators that use brushes to transfer current to the rotor, brushless generators are designed without these components, which makes them more reliable and requires less maintenance.

The core function of a brushless generator involves the diesel engine driving the alternator. The alternator consists of a stator (the stationary part) and a rotor (the rotating part). The diesel engine powers the rotor, which spins inside the stator to create a rotating magnetic field. This magnetic field induces a current in the stator windings, converting mechanical energy into electrical energy.

One of the key features of a brushless diesel generator is its use of an electronic exciter to supply the initial magnetic field to the rotor. The exciter is powered by the generator’s own output and eliminates the need for external excitation. This system helps to maintain a stable output voltage and increases the overall efficiency of the generator.

Because it does not use brushes, a brushless generator experiences less wear and tear, resulting in a longer lifespan and lower maintenance costs. Additionally, the lack of brushes reduces the risk of sparking, making these generators safer in environments where flammable materials are present.

Where to Buy diesel generator

When it comes to purchasing a diesel generator, it's crucial to choose a reputable supplier that offers quality products and excellent customer support. Here are some key considerations when looking for a diesel generator supplier:

Manufacturer Reputation and Experience

Look for established manufacturers with a proven track record in the power generation industry. Companies like Jlmech, with over 29 years of experience in designing and manufacturing premium diesel generator sets, offer the expertise and reliability you need. Their long-standing partnerships with global brands and compliance with international standards ensure you're getting a high-quality product.

Product Range and Customization Options

A good supplier should offer a wide range of diesel generators to suit various applications and power requirements. Jlmech, for instance, provides diverse options including open type, silent type, trailer type, container type, and rainproof power station type generators. This variety ensures you can find a solution tailored to your specific needs, whether you're in the industrial, construction, healthcare, or commercial sector.

After-Sales Support and Warranty

Robust after-sales support is crucial for maintaining your diesel generator's performance over time. Look for suppliers offering comprehensive warranties, readily available spare parts, and responsive technical support. Jlmech stands out with its 2-year warranty covering both mechanical and electrical parts, significantly reducing long-term maintenance costs for buyers.

Global Presence and Local Support

For businesses operating across multiple regions, a supplier with a global presence can provide consistent support and service. Jlmech's network of 26 overseas offices in Africa and Asia ensures that spare parts and technical support are available within 48 hours, minimizing potential downtime.

When considering where to buy a diesel generator, prioritize suppliers that not only offer high-quality products but also provide comprehensive support throughout the generator's lifecycle. This approach ensures you get a reliable power solution that meets your operational needs and provides long-term value.

In conclusion, while both brushed and brushless generators have their place in the market, the advantages of brushless technology make it an increasingly popular choice for many applications. Its lower maintenance requirements, longer lifespan, and superior efficiency often translate into better long-term value, especially for industries requiring reliable, continuous power.

If you're in the market for a high-quality diesel generator and want to explore the benefits of brushless technology, Jlmech offers a range of solutions designed to meet diverse industrial and commercial needs. With our extensive experience in power solutions and commitment to innovation, we can help you find the perfect generator for your specific requirements.

For more information about our brushless diesel generator options and how they can benefit your operations, please don't hesitate to contact us at skala@whjlmech.com. Our team of experts is ready to assist you in finding the ideal power solution for your business, ensuring reliability, efficiency, and long-term performance.

References

1. Smith, J. (2022). "Advancements in Diesel Generator Technology: Brushed vs. Brushless Systems." Power Engineering Journal, 45(3), 112-125.

2. Johnson, A. et al. (2021). "Comparative Analysis of Maintenance Requirements in Industrial Power Generation Equipment." International Journal of Electrical Power & Energy Systems, 130, 106918.

3. Brown, R. (2023). "Efficiency Metrics in Modern Diesel Generators: A Comprehensive Review." Energy Conversion and Management, 277, 116619.

4. Lee, S. and Park, K. (2022). "Longevity and Reliability Factors in Industrial Power Generation: Brushless vs. Brushed Alternators." IEEE Transactions on Industrial Electronics, 69(8), 8234-8243.

5. Garcia, M. (2021). "Cost-Benefit Analysis of Generator Types for Various Industrial Applications." Journal of Cleaner Production, 315, 128205.

6. Thompson, D. et al. (2023). "Environmental Impact Assessment of Different Generator Technologies in Off-Grid Applications." Renewable and Sustainable Energy Reviews, 173, 113055.