What is a parallel capable generator?

In today's world, having a reliable power supply is crucial for businesses, events, and emergency backup systems. Sometimes, a single generator just isn't enough to meet your power needs. This is where a parallel capable generator comes into play. Simply put, a parallel capable generator is designed to be safely connected to one or more other generators. This allows their combined power outputs to be summed together, creating a single, more powerful energy source. Think of it like harnessing the strength of multiple workhorses to pull a heavier load than any one could manage alone. Understanding what a parallel capable generator is and how it functions can open up new possibilities for scalable, efficient, and redundant power solutions for your operations .

How It Works

The core idea behind a parallel capable generator system is synchronization. It's not as simple as just plugging two generators together; they need to work in perfect harmony.

The Goal: The process, often called synchronization or paralleling, involves matching the output of each generator so their frequencies and voltage waveforms align perfectly .

The Process: Before the generators' outputs are connected via a common electrical bus, their voltage, frequency, and phase sequence must be synchronized . This ensures that when the connection is made, they act as a single, cohesive unit rather than fighting against each other, which could cause damage.

The Result: Once synchronized, these generators share the total electrical load proportionally. If one generator in a parallel system is rated for 500kVA and another for 500kVA, when connected, they can provide a combined 1000kVA of power .

Key Benefits

Investing in a parallel capable generator system offers several compelling advantages over relying on a single, larger unit.

Scalability and Flexibility: You can start with one generator and add more as your power needs grow. This is far more flexible than buying an oversized unit upfront. For example, if a factory expands, it can add a second generator to its existing one to meet new power demands .

Enhanced Redundancy and Reliability: If you have multiple generators running in parallel and one fails, the others can continue to power your critical loads. This provides a crucial safety net. For a 2000kVA requirement, using six 500kVA units in parallel means if one fails, you still have 2500kVA of power, avoiding a total blackout .

Cost-Effectiveness: In many cases, using multiple smaller, standardized units can be more economical than purchasing one very large, custom generator. Smaller units are often more mass-produced and can be easier and cheaper to transport and install .

Maintenance and Serviceability: With a parallel system, you can take one generator offline for scheduled maintenance while the others continue to supply power, ensuring your operations are never interrupted.

Common Applications

Parallel capable generator systems are incredibly versatile and are used in a wide range of scenarios.

Large Industrial Sites: Factories and manufacturing plants with high and fluctuating power demands use parallel systems to scale their power supply up or down as needed .

Data Centers and Hospitals: These facilities require uninterrupted power. Parallel systems provide the necessary redundancy to ensure that a single generator failure does not lead to downtime.

Construction Sites: Power requirements can change as a project progresses. A parallel system allows crews to start with one generator and add more for larger equipment or phases of the project.

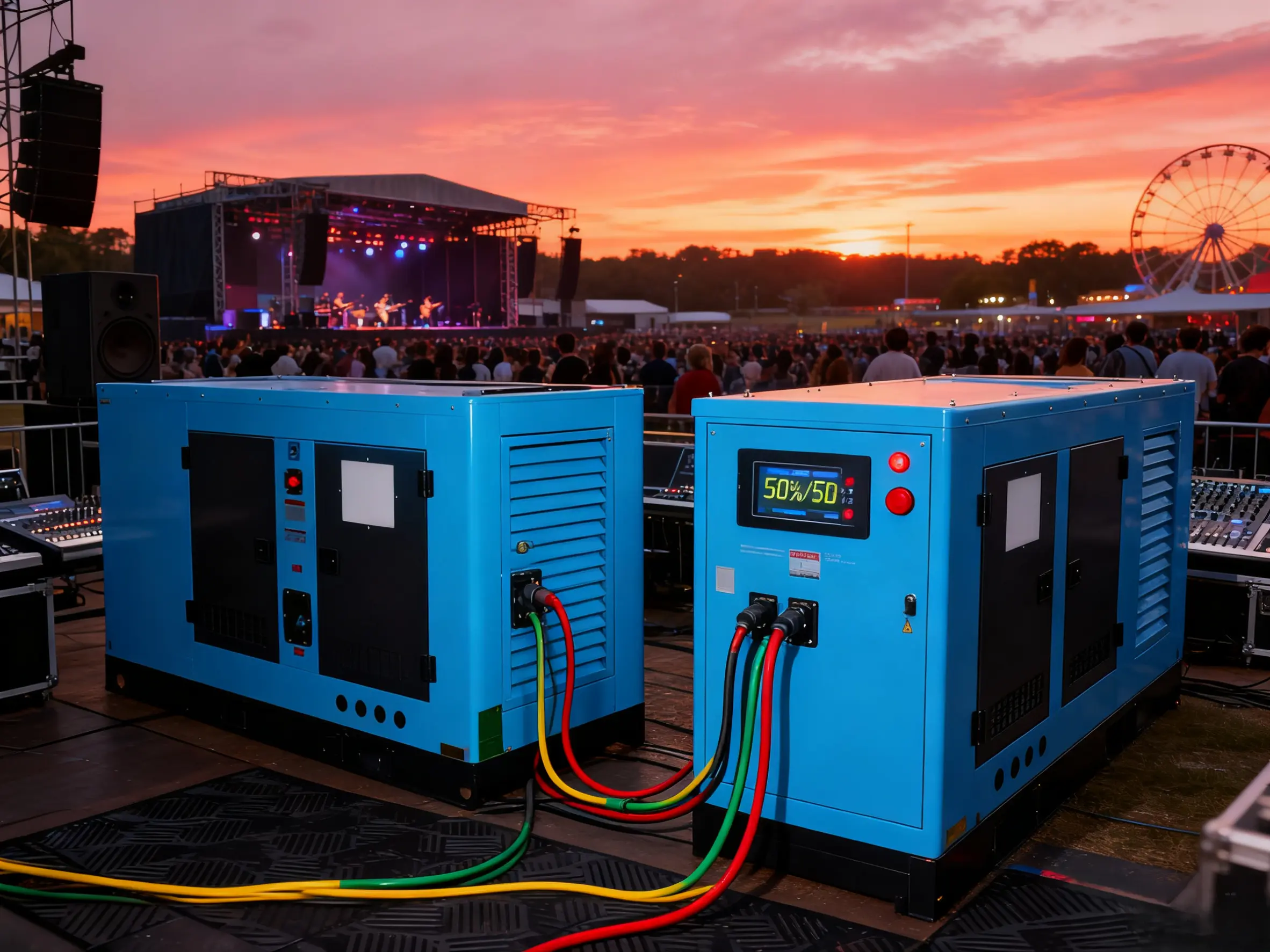

Events and Entertainment: Large outdoor concerts, festivals, and sporting events often use multiple generators in parallel to create the high-capacity, reliable power grid they need.

Required Components

To create a functional parallel system, you need more than just the generators themselves. Key components include:

The Generators: Each unit must be a parallel capable generator, designed with the necessary internal circuitry and control capabilities.

Control Panel: A specialized controller is the brain of the operation. It monitors each generator's output and automatically adjusts the engine speed and voltage to ensure perfect synchronization before connecting them. These are often advanced systems like Deepsea or Smartgen panels .

Parallel Connection Kit: This includes the cabling, busbars, and connection hardware that physically link the generators together.

Synchronization Equipment: This includes sensors and relays that ensure the generators are matched in frequency, voltage, and phase angle before the connection is closed .

Synchronization Process

Synchronization is the most critical technical step in paralleling generators. Here's a simplified breakdown:

Voltage Matching: The control system ensures all generators have the same output voltage.

Frequency Matching: The engine speeds are adjusted until the output frequency (Hz) of all generators is identical.

Phase Matching: The systems ensure that the voltage waveforms of all generators are rising and falling at the exact same moment.

Connection: Once all parameters are perfectly matched, the controller closes the circuit breaker, connecting the generators to the common busbar. They are now operating in parallel.

Installation & Safety

Proper installation and adherence to safety protocols are non-negotiable.

Professional Installation is a Must: Setting up a parallel generator system is complex and should only be done by qualified and experienced technicians. Incorrect setup can lead to severe generator damage or safety hazards.

Automatic Safety Systems: Modern systems have built-in protection to prevent paralleling if the conditions are not met and to disconnect a faulty generator automatically.

Regular Testing and Maintenance: To ensure the system will work flawlessly when needed, regular testing and maintenance of both the generators and the paralleling equipment are essential.

Conclusion

A parallel capable generator is more than just a power source; it's a cornerstone of a modern, flexible, and resilient power system. By allowing multiple units to work together seamlessly, it provides a solution that is scalable, reliable, and cost-effective for a wide range of applications. Whether for ensuring business continuity, powering large-scale events, or facilitating industrial growth, the ability to parallel generators offers a powerful strategic advantage.

If you are considering a robust power solution for your business, our team of experts is here to help you design and implement the ideal parallel generator system tailored to your unique needs. For a personalized consultation, please contact us at skala@whjlmech.com.

References

Johnson, M. (2022). Emergency Power Systems: A Comprehensive Guide to High-Speed Diesel Generators. Power Engineering Quarterly, 45(3), 78-92.

Synchronous Generator Parallel Operation PPT. (2021). Parallel Connection Operation of Synchronous Generator .

Sohu News. (2021). What is a Parallel Diesel Generator?

Alibaba Product Description. (2025). *JW-G1 Parallel Operation Generator* .

Elecfans. (2023). Synchronous Generator Parallel Methods .

VIEW MOREFarm application diesel generator

VIEW MOREFarm application diesel generator VIEW MOREElectric start diesel generator

VIEW MOREElectric start diesel generator VIEW MORENew 4 Cylinders Water Cooled Diesel Generator Set

VIEW MORENew 4 Cylinders Water Cooled Diesel Generator Set VIEW MOREdiesel generator 100 kw

VIEW MOREdiesel generator 100 kw VIEW MOREland auger machine

VIEW MOREland auger machine VIEW MOREsilent diesel generator 250kva

VIEW MOREsilent diesel generator 250kva VIEW MORE3 phase perkins generator 60kva diesel generator

VIEW MORE3 phase perkins generator 60kva diesel generator VIEW MOREdiesel generators yuchai 62 kva

VIEW MOREdiesel generators yuchai 62 kva