What is a generator control circuit?

A generator control circuit is the central nervous system of any power generation unit. It is the network of electrical components and logic systems that manage, monitor, and protect the generator during operation. At the heart of this system lies the generator control board, which integrates these functions into a single, sophisticated unit. Understanding the control circuit is essential for ensuring reliability, safety, and efficiency in power generation systems.

Core Functions of the Control Circuit

The generator control circuit performs several critical tasks to maintain optimal operation:

Automatic Start/Stop: Initiates the generator during power outages and shuts it down when power is restored or when maintenance is required.

Parameter Monitoring: Tracks essential values such as voltage, frequency, engine speed, coolant temperature, and oil pressure.

Fault Protection: Detects abnormalities like overloads, low oil pressure, or overheating and triggers alarms or shutdowns to prevent damage.

Load Management: Regulates power output based on demand and can synchronize multiple generators when used in parallel.

Communication: Enables remote monitoring and control through interfaces such as Modbus, CAN bus, or Ethernet.

These functions are seamlessly executed by the generator control board, ensuring smooth and autonomous operation.

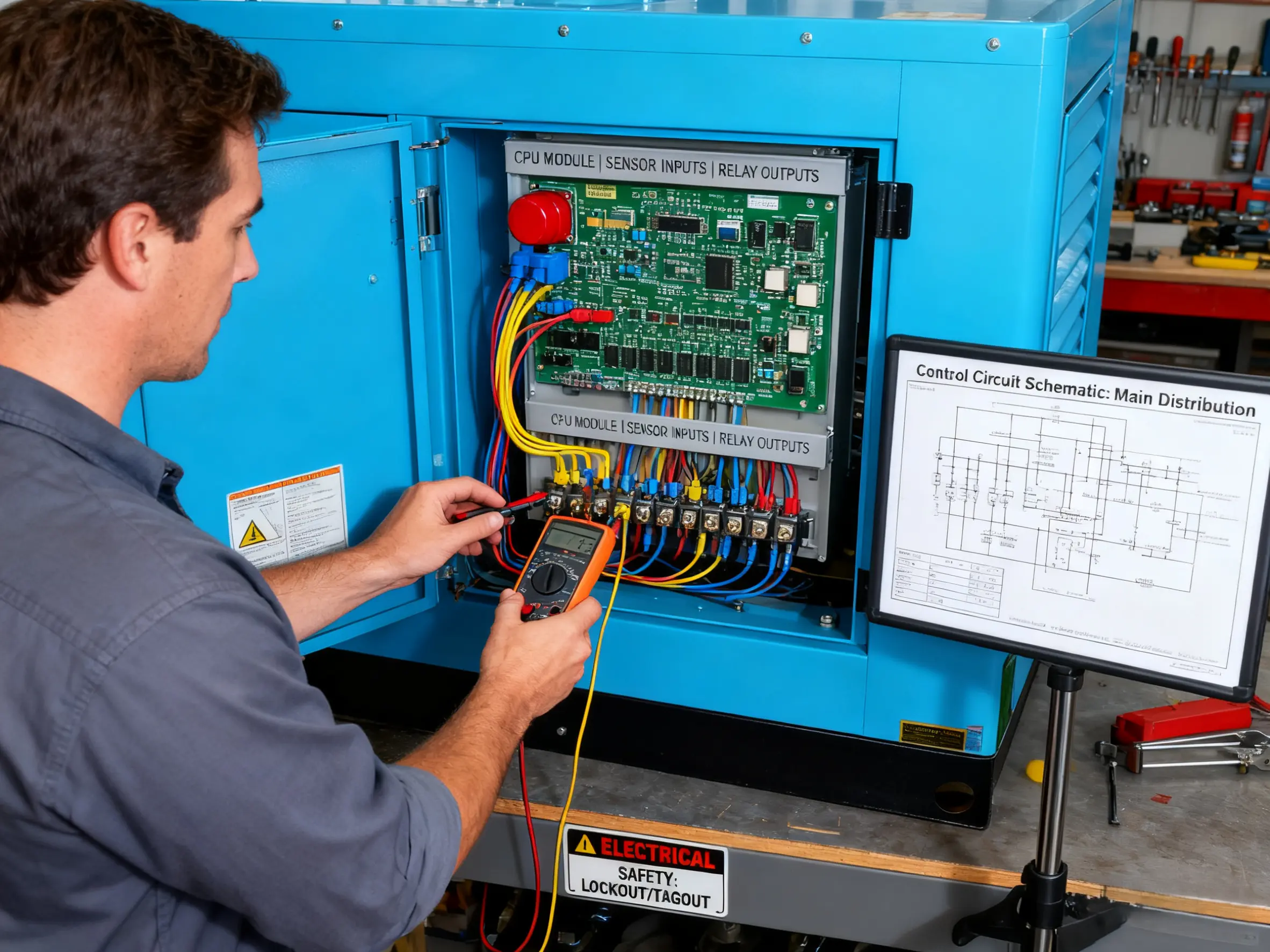

Key Components

A typical generator control circuit consists of the following elements, many of which are embedded within the generator control board:

Sensors: Measure physical parameters like temperature, pressure, and speed.

Actuators: Include contactors, relays, and circuit breakers that execute commands.

Microprocessor: The brain of the system, processing inputs and making real-time decisions.

Power Supply: Provides stable voltage to the control components.

Human-Machine Interface (HMI): Allows users to interact with the system through displays, buttons, and indicators.

Communication Modules: Enable connectivity for remote access and integration with broader control systems.

How It Works

The control circuit operates through a continuous cycle of monitoring, processing, and action:

Data Collection: Sensors gather real-time information on generator performance.

Signal Processing: The microprocessor analyzes this data against predefined thresholds.

Decision Making: If parameters deviate from safe limits, the control logic determines the necessary response.

Output Execution: Commands are sent to actuators to adjust operation, activate alarms, or initiate shutdowns.

Feedback Loop: The system continuously verifies that actions have resolved the issue, creating a closed-loop control environment.

This process ensures operational stability and minimizes the need for manual intervention.

Types of Control Circuits

Generator control circuits vary in complexity and functionality:

Manual Control Circuits: Basic systems requiring operator intervention for starting, stopping, and monitoring.

Semi-Automatic Systems: Automate certain functions, such as startup and shutdown, but may require manual load management.

Fully Automatic Circuits: Capable of fully autonomous operation, including self-diagnosis and response to faults.

Parallel Systems: Designed to manage multiple generators, distributing load efficiently and maintaining synchronization.

Modern generator control board designs often support configurability, allowing them to be adapted to various circuit types and applications.

Importance in Generator Performance

A well-designed control circuit is vital for:

Reliability: Reducing downtime through proactive fault detection and mitigation.

Safety: Protecting both the generator and connected equipment from electrical and mechanical hazards.

Efficiency: Optimizing fuel consumption and load handling to reduce operational costs.

User Convenience: Providing clear insights and control options for operators.

Investing in an advanced generator control board ensures that these benefits are fully realized, adding value to any power generation system.

Conclusion

The generator control circuit is the intelligence behind reliable power generation, integrating monitoring, protection, and control into a cohesive system. From basic manual setups to fully automated solutions, the right control circuit—and the generator control board that brings it to life—can significantly enhance performance, safety, and usability.

At JLMECH, we combine decades of expertise in power generation with a steadfast commitment to quality and innovation. Whether you are looking to upgrade an existing system or integrate a control solution into a new generator, our team is ready to assist.

Reach out to us for expert guidance and custom-tailored power solutions. Email us at skala@whjlmech.com to discuss your needs and discover how JLMECH can empower your operations with reliability and precision.

References

Anderson, T. (2021). Generator Control Circuits: Design and Application in Modern Power Systems. Journal of Power Engineering, 22(4), 56-68.

Roberts, K., & Miller, L. (2020). From Relays to Microprocessors: Evolution of Generator Control Systems. International Journal of Electrical Engineering, 11(3), 89-101.

Wilkinson, S. (2019). Control Systems for Diesel Generators (3rd ed.). New York: Elsevier Science.

Evans, P. (2022). Integration of Digital Control Boards in Power Generation Equipment. IEEE Transactions on Industrial Electronics, 70(2), 134-147.

International Electrotechnical Commission. (2018). *IEC 60204-1: Safety of Machinery—Electrical Equipment of Machines*. Geneva, Switzerland.