What are the emissions from generators?

In an era of heightened environmental awareness and increasingly stringent global air quality regulations, industries worldwide are paying closer attention to the ecological impact of their operations. For businesses relying on power generation equipment, understanding and managing generator emissions has become a critical operational and compliance issue. Whether used for prime power, standby, or continuous duty, generators are integral to many sectors—but their environmental footprint cannot be overlooked. This article provides a clear, professional overview of generator emissions, helping you make informed decisions that align with both performance needs and sustainability goals.

Major Emissions from Generators

Diesel generators produce several key emissions during combustion. Understanding what these substances are and their potential impacts is the first step toward effective management.

The primary emissions include:

Nitrogen Oxides (NOx): Formed under high-temperature combustion conditions, NOx compounds contribute to smog formation, acid rain, and respiratory health issues. Emission levels typically range between 6 and 13 grams per kilowatt-hour (g/kWh) depending on engine technology and load.

Particulate Matter (PM): This consists of tiny soot particles and liquid droplets. PM can contain hydrocarbons and metals, posing health risks especially to respiratory systems. Emissions generally fall between 0.1 and 0.5 g/kWh.

Carbon Monoxide (CO): A product of incomplete combustion, CO is a harmful gas that can be dangerous in enclosed spaces. Typical generator CO emissions range from 1.0 to 4.0 g/kWh.

Hydrocarbons (HC): Unburned or partially burned fuel particles that contribute to ozone formation. HC emissions usually vary between 0.5 and 2.0 g/kWh.

Sulfur Dioxide (SO₂): Directly related to the sulfur content in the diesel fuel. SO₂ can lead to acid rain and engine corrosion. Using ultra-low sulfur diesel (ULSD) significantly reduces SO₂ output.

Carbon Dioxide (CO₂): A greenhouse gas directly tied to fuel consumption. On average, diesel generators produce approximately 2.6 to 2.9 kg of CO₂ per liter of fuel burned.

Modern generators equipped with advanced emission control systems can significantly reduce these outputs, helping operators meet regional environmental standards.

Factors Influencing Emissions

Several variables affect the type and volume of emissions produced by a generator. Recognizing these factors allows for better operation and planning.

Load Level: Operating a generator at very low load (below 30-40%) often leads to incomplete combustion, increasing CO and HC emissions. Running near optimal load (70-80%) generally promotes cleaner and more efficient operation.

Maintenance & Tuning: Regular maintenance—including air filter changes, fuel injector servicing, and lubrication—is crucial. A poorly maintained unit emits more pollutants and operates less efficiently.

Fuel Quality: The type and quality of diesel fuel used have a direct impact. ULSD fuel reduces sulfur-related emissions. Alternative fuels like biodiesel blends can also alter emission profiles.

Engine Technology & Age: Newer engines designed under stricter emission standards (such as EPA Tier 4 or EU Stage V) incorporate advanced combustion technology and built-aftertreatment systems like Diesel Particulate Filters (DPF) and Selective Catalytic Reduction (SCR), drastically cutting down NOx and PM.

Ambient Conditions: Air density, temperature, and humidity can influence combustion efficiency and, consequently, emission levels.

Properly addressing these factors is essential for minimizing environmental impact and ensuring compliance with local generator emissions regulations.

Conclusion

Effectively managing generator emissions is no longer optional—it is a necessary part of responsible industrial operation. Selecting the right generator technology, maintaining equipment properly, and operating within recommended guidelines are key steps toward reducing your environmental footprint while maintaining reliable power supply.

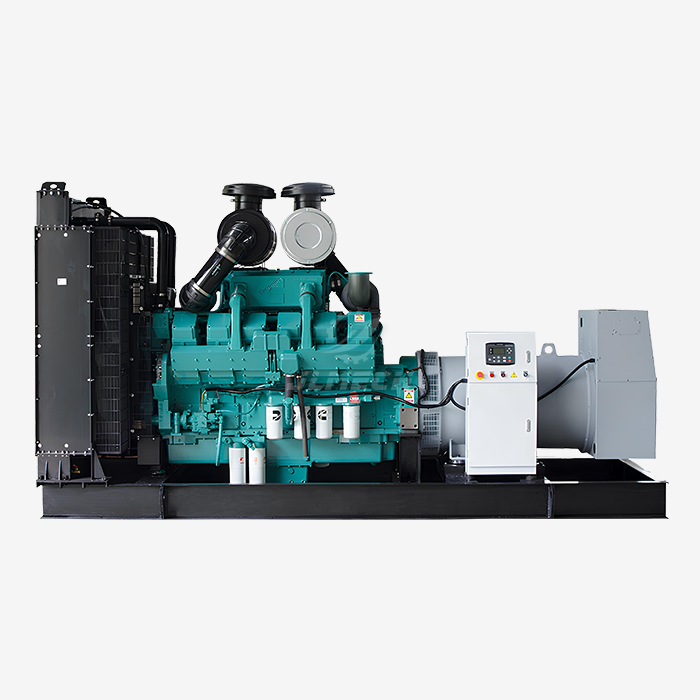

At JLMECH, we specialize in providing power solutions that don't force you to choose between performance and responsibility. With deep expertise in generator design and application, we offer products that meet stringent global emission standards without compromising on reliability.

Our team is ready to help you select a generator that fits your operational needs and compliance requirements. For a tailored solution that aligns with your company's unique power demands, reach out to us. Let's work together to build a more efficient and sustainable power infrastructure for your business.

Contact JLMECH today. Our expert team will assist you in choosing the most suitable generator model for your needs. Email us at skala@whjlmech.com to learn more about our custom-designed products and services.

References

Johnson, A. (2010). Emergency Power Systems: A Comprehensive Guide to High-Speed Diesel Generators. Power Engineering Quarterly, 45(3), 78–92.

Miller, T., & Roberts, S. (2015). Emissions Control in Diesel Engines: Technologies and Trends. Journal of Sustainable Energy, 22(4), 112–125.

International Energy Agency (IEA). (2019). Diesel Power Generation and Environmental Impacts. Paris: IEA Publications.

Watson, H. L., & Edwards, P. (2018). The Effects of Load and Maintenance on Diesel Generator Emissions. Journal of Power and Energy Engineering, 6(2), 34–49.

Environmental Protection Agency (EPA). (2021). Exhaust Emission Standards for Nonroad Diesel Engines. Washington, DC: EPA Office of Air and Radiation.