What are the basic requirements for installing a fuel tank?

For any diesel generator system, the fuel tank installation represents a critical component that directly impacts operational reliability, safety, and performance. Proper diesel generator fuel tank installation involves careful consideration of placement, materials, sizing, and compliance with safety standards to ensure uninterrupted power supply. Whether you're installing a new generator system or upgrading an existing one, understanding the fundamental requirements for diesel generator fuel tank installation is essential for creating a safe, efficient, and reliable power solution. This comprehensive guide examines the key factors that ensure your fuel storage system meets both operational needs and regulatory requirements.

Tank Location and Placement

The positioning of your fuel tank significantly affects both safety and functionality. Several critical factors must be considered during site selection.

Safety Distance Requirements: Tanks should be positioned a safe distance from the generator itself and any potential fire hazards. The location should be clearly visible or situated in a dedicated storage area, with strict no-smoking policies enforced in the vicinity.

Height Restrictions: The maximum fuel level in the tank should not exceed 2.5 meters above the generator baseplate. If using a larger storage tank positioned higher than this limit, an intermediate day tank must be installed between the main tank and the generator to maintain proper fuel head pressure.

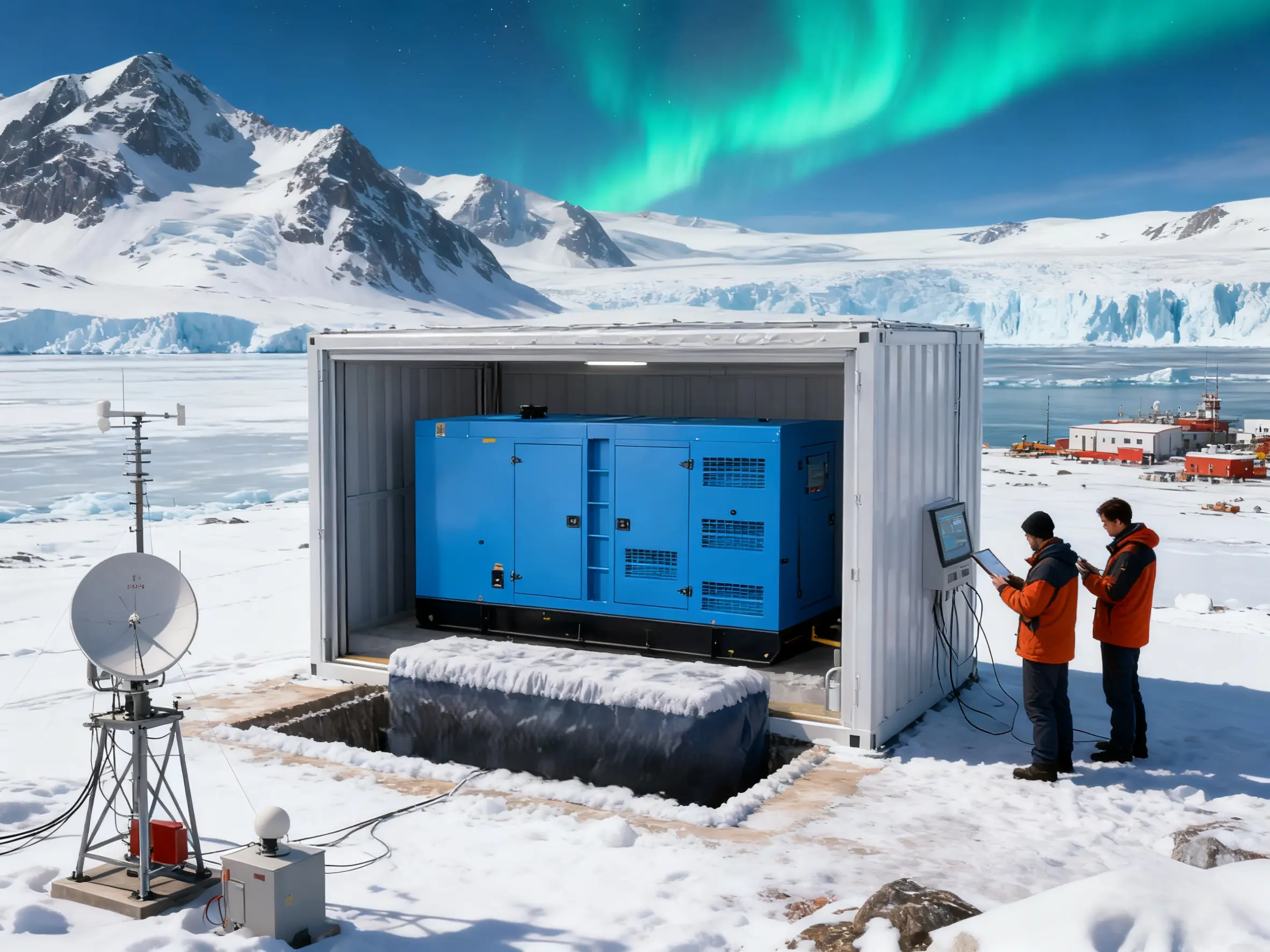

Accessibility and Serviceability: The tank location should allow easy access for refueling, maintenance, and inspection. For underground tanks, ensure proper waterproofing, ventilation, and accessibility for cleaning. Outdoor tanks should be positioned in areas that won't be affected by freezing conditions, which can increase fuel viscosity and flow resistance.

Environmental Considerations: Avoid locations where the tank will be exposed to extreme temperature variations, direct sunlight, or potential physical damage.

Material Selection and Construction

The materials used in fuel tank construction play a crucial role in system longevity and fuel quality.

Appropriate Materials: Tanks should be constructed from stainless steel or untreated carbon steel. These materials provide excellent durability and compatibility with diesel fuel.

Prohibited Materials: Never use galvanized steel or zinc-coated materials for tanks or piping. These coatings can react with sulfur compounds in diesel fuel, forming particles that can clog filters and injectors.

Internal Coatings: Avoid paints or other coatings on the internal surfaces of the tank. These can degrade over time, contaminating the fuel and potentially causing engine damage.

Design Features: Tanks should include baffle plates to minimize fuel sloshing. The bottom should be slightly sloped (approximately 2 degrees) toward a drain valve to facilitate water and sediment removal.

Tank Sizing and Capacity

Correctly sizing your fuel tank ensures adequate runtime while considering practical constraints.

Day Tank Capacity: A common recommendation is to size day tanks to hold at least 8 times the hourly fuel consumption at full load. This provides sufficient fuel for extended operation while allowing for maintenance intervals.

Fuel Consumption Estimation: A useful rule of thumb for estimating diesel consumption is: Fuel (L/h) = 0.27 × P (kW), where P is the generator's rated power. For a 100kW generator, this would be approximately 27 liters per hour at full load.

Storage Tank Capacity: For backup systems, consider a larger storage tank sized to meet your anticipated runtime requirements. One calculation method involves estimating fuel needs based on expected operation hours, adding a reserve for testing, and including an additional 6% for expansion and sediment space.

Practical Considerations: Balance capacity needs with space constraints, budget limitations, and any regulatory restrictions on above-ground fuel storage quantities.

Fuel System Piping and Connections

Proper piping installation ensures consistent fuel delivery and prevents common operational issues.

Pipe Material Requirements: Use black iron pipes rather than galvanized pipes. Connections between the fixed piping system and the generator should be made with flexible hoses to absorb vibration and prevent leaks.

Supply Line Configuration: The supply pipe inlet should be positioned approximately 50mm (2 inches) above the bottom of the tank. This prevents sediment and water from being drawn into the fuel system.

Return Line Considerations: The return line should discharge fuel in a way that doesn't create turbulence or air bubbles in the supply line. Both supply and return lines should be the same diameter.

Vent Requirements: All tanks must have properly sized vent pipes to prevent pressure buildup or vacuum formation during filling and fuel draw. Vents should be protected with breather filters to prevent contamination.

Safety and Regulatory Compliance

Adhering to safety standards and regulations protects both personnel and property.

Fire Safety Regulations: Follow all local fire codes regarding tank placement, containment, and protection. The storage area should have a fire resistance rating of at least two hours.

Secondary Containment: Consider bunding or diking around above-ground tanks to contain potential spills. The containment volume should typically equal at least 110% of the tank's capacity.

Grounding and Bonding: Properly ground all tanks and piping to prevent static electricity buildup, which could ignite fuel vapors.

Ventilation Requirements: Tank rooms require adequate ventilation to prevent accumulation of flammable vapors.

Local Regulations: Compliance with local, national, and insurance regulations is mandatory for any fuel installation. These may include specific requirements for tank design, placement, and protection.

Foundation and Support Structure

A proper foundation ensures tank stability and prevents structural issues.

Base Requirements: Tank foundations should be level, stable, and capable of supporting the full weight of the tank when filled. For large tanks, concrete foundations are typically required.

Foundation Height: Concrete bases should be at least 300mm thick and extend beyond the tank footprint to provide proper support.

Corrosion Protection: Use non-combustible, corrosion-resistant materials such as hot-dip galvanized steel for tank supports and retaining straps.

Underground Tank Considerations: Underground tanks require carefully engineered foundations and backfill specifications to prevent shifting or damage.

Venting and Overflow Protection

Proper venting is essential for safe tank operation and environmental protection.

Vent Sizing: Vents must be appropriately sized for both filling and withdrawal rates to prevent pressure buildup or vacuum collapse.

Vent Termination: Route vent pipes to discharge in a safe location where vapors won't enter buildings or create fire hazards.

Overflow Prevention: Install automatic shutoff valves or overfill prevention devices when tanks are filled remotely or without direct visual monitoring.

Emergency Venting: Larger tanks may require emergency venting capacity to handle excessive pressure conditions during fire exposure.

Maintenance and Monitoring Features

Incorporating proper access and monitoring points simplifies ongoing maintenance.

Inspection Access: Provide adequate space around tanks for visual inspection, maintenance, and potential replacement.

Drain Valves: Install readily accessible drain valves at the lowest point of tanks to remove water and sediment.

Level Monitoring: Include level gauges, sight glasses, or electronic sensors to monitor fuel quantity.

Cleanout Access: Larger tanks should have manways or other openings to allow internal inspection and cleaning.

Conclusion

Proper diesel generator fuel tank installation requires careful attention to location, materials, sizing, piping, and safety considerations. By addressing these fundamental requirements during the planning phase, you can ensure a reliable fuel supply system that supports generator performance while meeting all regulatory obligations. A well-executed diesel generator fuel tank installation provides the foundation for uninterrupted power availability, whether for emergency backup, prime power, or peak shaving applications. Remember that proper installation not only ensures operational reliability but also significantly reduces long-term maintenance requirements and potential environmental hazards.

Our technical team specializes in helping clients design and implement complete fuel system solutions for their specific generator applications. For professional guidance on your diesel generator fuel tank installation requirements, contact our experts at skala@whjlmech.com.

References

Johnson, M. (2022). Emergency Power Systems: A Comprehensive Guide to High-Speed Diesel Generators. Power Engineering Quarterly, 45(3), 78-92.

FG Wilson. (1997). Generating Set Installation Manual.

Jiangsu Xingguang Power Group. (2017). Diesel Generator Set Fuel Tank and Pipeline Installation.

Internal Combustion Engine and Components. (2017). Equipment Installation Logic and Methods in Diesel Power Plants.

Neighbor. (2022). Fuel Generator Set Installation Considerations.