What are industrial generators?

In today's interconnected industrial landscape, a continuous and reliable power supply is the lifeblood of operations across countless sectors. From manufacturing plants and data centers to healthcare facilities and construction sites, any interruption in electricity can lead to catastrophic production losses, data corruption, and significant financial damage. An industrial generator is a robust, stationary or mobile power system designed specifically to provide primary, standby, or emergency electrical power for large-scale commercial, industrial, and institutional applications. Unlike residential models, these are heavy-duty machines engineered for high power output, prolonged operation, and unparalleled durability in demanding environments. Understanding what an industrial generator is, how it works, and how to select the right model is fundamental to ensuring your business's operational resilience and continuity.

Core Components and Functionality

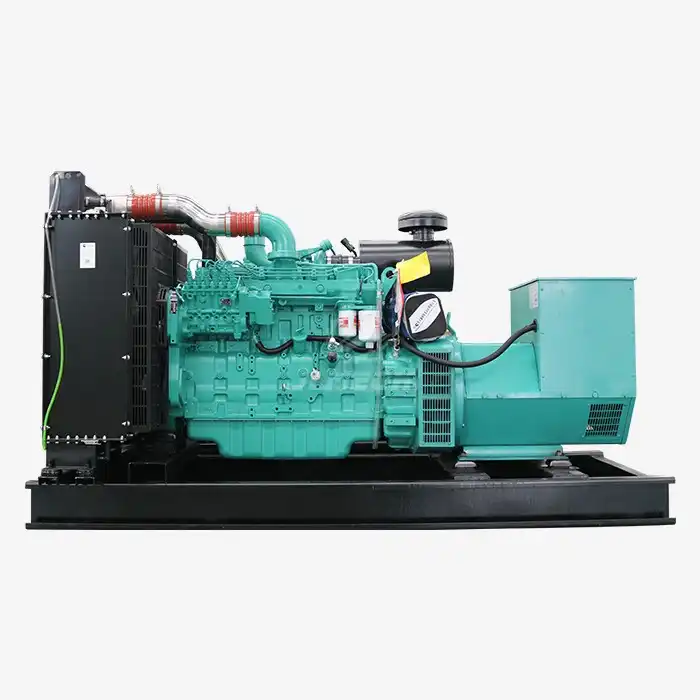

An industrial generator set, or genset, is more than just an engine and an alternator; it is a sophisticated integrated system. Its operation is based on the principle of electromagnetic induction, where mechanical energy is converted into electrical energy . The key components work in unison to achieve this:

Engine: The source of mechanical power. Industrial generators typically use diesel, natural gas, or other fuel engines designed for long-term reliability and high torque.

Alternator (Generator): The component that converts the engine's mechanical energy into electrical energy. It consists of a rotor (which creates a rotating magnetic field) and a stator (where the electric current is induced) .

Fuel System: Includes a high-capacity fuel tank, filters, pumps, and piping to ensure a steady and clean fuel supply for extended runtimes.

Voltage Regulator & Control Panel: The brain of the system. It ensures stable output voltage by controlling the excitation current , and provides interfaces for monitoring parameters like voltage, frequency, and oil pressure, while housing critical controls and safety alarms.

Cooling and Exhaust Systems: Manage the significant heat generated by the engine and safely expel combustion gases.

Lubrication System: Essential for minimizing wear and tear on moving parts, ensuring the longevity of the engine.

Primary Applications in Industry

The versatility and power of an industrial generator make it indispensable across a wide spectrum of applications. They are deployed in scenarios where power reliability is non-negotiable.

Standby Power for Facilities: Providing automatic backup power for hospitals, data centers, water treatment plants, and high-rise buildings during grid outages.

Prime Power for Remote Locations: Serving as the main source of electricity for mining operations, agricultural operations, and offshore rigs where the utility grid is inaccessible.

Continuous Power for Manufacturing: Ensuring uninterrupted operation of production lines, industrial processes, and sensitive machinery where even a brief power dip can cause massive disruptions.

Peak Shaving: Supplying supplemental power during periods of high energy demand to help businesses avoid costly utility peak-demand charges.

Key Types and Power Sources

Industrial generators are categorized based on their power source and operational purpose, allowing businesses to select the optimal model for their specific needs.

By Power Source:

Diesel Generators: The most common type for heavy-duty applications, prized for their durability, torque, and fuel efficiency, especially in standby roles .

Natural Gas Generators: Often used in applications requiring cleaner emissions and where a continuous gas supply is available, suitable for both standby and prime power .

Combined Heat and Power (CHP): Also known as cogeneration, these highly efficient units generate electricity and capture waste heat for heating or industrial processes .

By Operational Role:

Standby Generators: Permanently installed and designed to automatically start and take over the electrical load within seconds of a utility power failure.

Prime Power Generators: Intended to be the primary source of power for extended periods, often in off-grid applications.

Continuous Generators: Similar to prime power, designed for unlimited operation at a constant load.

Critical Selection Criteria

Choosing the right industrial generator is a complex decision that impacts your operational efficiency and bottom line. Several key factors must be considered:

Power Rating (kW/kVA): Accurately calculate your total load, including the starting current of large motors, to determine the required kW (kilowatt) and kVA (kilo Volt-Ampere) rating. Undersizing leads to failure, while oversizing leads to inefficiency.

Fuel Type: Evaluate the availability, storage requirements, and long-term cost of diesel, natural gas, or other fuels in your region.

Voltage Regulation: The generator must maintain a stable voltage output . The choice of an Automatic Voltage Regulator (AVR) is critical for protecting sensitive electronic equipment from damage caused by fluctuations.

Duty Cycle: Decide whether the unit is for emergency standby, prime power, or continuous operation, as this affects the engine's design and rating.

Environmental Conditions: Consider altitude, ambient temperature, and humidity, as these factors can derate the generator's output.

Acoustic Enclosures: For noise-sensitive environments, specify the required level of sound attenuation.

Installation, Compliance, and Maintenance

Proper installation and rigorous maintenance are not optional; they are fundamental to the safety, performance, and longevity of your power asset.

Professional Installation: Must be performed by certified technicians, involving a reinforced concrete pad, correct fuel system plumbing, and compliant electrical integration with an Automatic Transfer Switch (ATS).

Regulatory Compliance: Installation and operation must adhere to local and international standards, which may include building codes, environmental emission regulations, and electrical safety standards.

Proactive Maintenance Schedule:

Daily/Weekly Checks: Fluid levels, coolant, and visual inspection for leaks.

Regular Service: Oil and filter changes, fuel filter replacement, and air filter cleaning/replacement based on running hours.

Load Bank Testing: Periodically running the generator under a full artificial load to verify performance and burn off accumulated wet stacking in diesel engines.

Professional Inspection: Annual thorough inspection by a qualified engineer to assess the entire system.

The Business Case: Cost of Ownership

Viewing an industrial generator as a capital investment requires a thorough understanding of the total cost of ownership (TCO), which extends far beyond the initial purchase price.

Initial Purchase Cost: The upfront cost of the generator set and its ancillary systems.

Installation & Civil Works: Costs for the pad, canopy, fuel tank installation, and electrical integration.

Operational Costs: The largest recurring expense, encompassing fuel consumption and routine maintenance (filters, oil, coolants).

Downtime Costs: While not a direct payment, the potential financial impact of a power outage is a key reason for the investment. A reliable generator is a form of insurance against these catastrophic losses.

Conclusion

An industrial generator is a critical asset that safeguards your operations, revenue, and reputation against the inevitable event of a power disruption. It is a sophisticated piece of engineering that requires careful selection, professional installation, and disciplined maintenance to fulfill its role effectively. Investing in the right generator solution is not merely a purchase; it is a strategic decision for ensuring business continuity and building a resilient enterprise.

Our team of power system specialists is ready to help you navigate the selection process and provide a generator solution that meets your specific operational and financial requirements. For a professional consultation, please contact us at skala@whjlmech.com.

References

International Organization for Standardization. (2018). Reciprocating internal combustion engine driven generating sets — Part 1: Application, ratings and performance (ISO 8528-1:2018).

Generator Manufacturers Association. (2021). Guidelines for Rating and Application of Generator Sets. GMA Technical Publication TP-101.

National Fire Protection Association. (2020). Standard for Emergency and Standby Power Systems (NFPA 110).

Khan, S. (2018). Electrical Aspects of Power Generation. In Industrial Power Systems. Taylor & Francis.