Key Features of the Heavy-Duty Industrial Diesel Generator

When it comes to powering large-scale operations or providing reliable backup during critical situations, industrial diesel generators stand out as the go-to solution. These powerhouses are engineered to deliver unwavering performance in the most demanding environments. From construction sites to data centers, and from hospitals to manufacturing plants, heavy-duty diesel generators are the backbone of uninterrupted power supply.

Understanding the key features of these robust machines is crucial for businesses and organizations that rely on consistent power output. Let's dive into what makes industrial diesel generators the preferred choice for heavy-duty applications, exploring their essential characteristics and the technology that drives their reliability.

What makes an industrial diesel generator "heavy-duty"?

The term "heavy-duty" in the context of industrial diesel generators refers to a combination of factors that contribute to their durability, power output, and ability to operate continuously under challenging conditions. These generators are built to withstand the rigors of industrial use and provide reliable power for extended periods.

Robust Construction and Materials

Heavy-duty industrial generators are constructed using high-grade materials capable of withstanding extreme temperatures, vibrations, and environmental stressors. The engine block, for instance, is typically made from cast iron or reinforced steel to ensure longevity and stability during operation.

Enhanced Cooling Systems

To maintain optimal performance during prolonged use, these generators feature advanced cooling systems. This often includes oversized radiators, high-capacity coolant pumps, and efficient fan designs that work together to dissipate heat effectively, even in high-temperature environments.

High-Capacity Fuel Systems

Industrial diesel generators are equipped with large fuel tanks and efficient fuel delivery systems. This allows for extended run times without the need for frequent refueling, which is crucial for applications requiring continuous power supply.

Top 5 must-have features in industrial-grade diesel generators

When selecting an industrial diesel generator, certain features are non-negotiable for ensuring optimal performance and reliability. Here are the top five features that should be present in any high-quality industrial generator:

1. Advanced Electronic Control Systems

Modern industrial generators come equipped with sophisticated electronic control panels that monitor and manage all aspects of generator operation. These systems provide real-time data on power output, fuel consumption, and engine health, allowing for proactive maintenance and efficient operation.

2. Automatic Voltage Regulation (AVR)

AVR systems are essential for maintaining stable voltage output regardless of load fluctuations. This feature ensures that sensitive equipment receives clean, consistent power, protecting against damage caused by voltage spikes or drops.

3. Heavy-Duty Alternators

Industrial-grade generators utilize robust alternators designed for continuous duty. These alternators are built to handle high starting loads and maintain efficiency under varying load conditions, ensuring reliable power generation in demanding industrial settings.

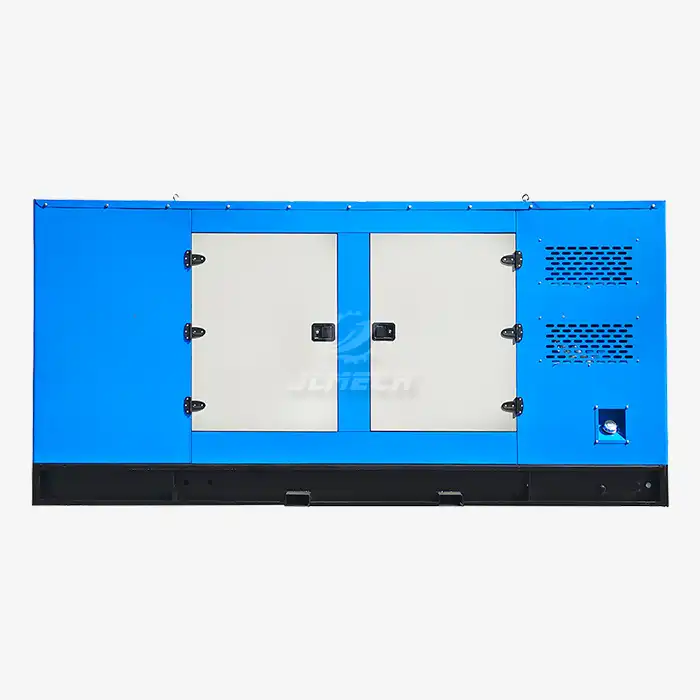

4. Sound Attenuation

While power output is crucial, noise reduction is equally important, especially in urban or noise-sensitive environments. High-quality industrial generators incorporate advanced soundproofing technologies to minimize operational noise without compromising performance.

5. Environmental Protection Features

Modern industrial generators are designed with environmental considerations in mind. This includes features like spill containment basins, advanced emission control systems, and compatibility with biodiesel fuels to meet stringent environmental regulations.

How do heavy-duty diesel generators ensure 24/7 reliability?

The ability to provide uninterrupted power is a hallmark of heavy-duty industrial diesel generators. This round-the-clock reliability is achieved through a combination of design features and operational strategies:

Redundant Systems and Fail-Safes

Industrial generators often incorporate redundant components and fail-safe mechanisms. This might include duplicate fuel pumps, multiple battery chargers, or backup control systems. If one component fails, the backup immediately takes over, ensuring continuous operation.

Intelligent Load Management

Advanced load management systems in industrial generators can prioritize power distribution to critical systems during peak demand or emergencies. This ensures that essential operations receive uninterrupted power even when the generator is approaching its capacity limits.

Predictive Maintenance Technology

Many modern industrial generators are equipped with sensors and analytics software that can predict potential issues before they lead to failures. This allows for proactive maintenance, minimizing downtime and extending the generator's operational life.

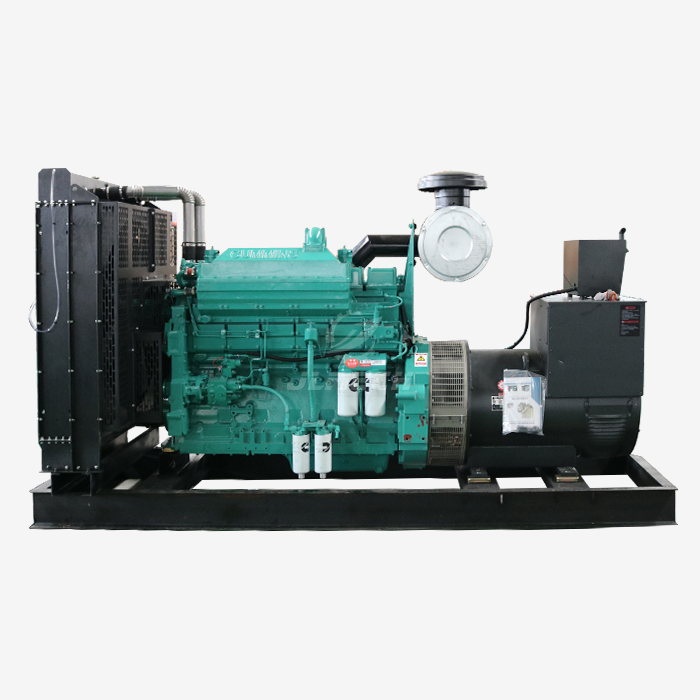

At Jlmech, we understand the critical importance of reliable power solutions for industrial applications. Our range of industrial diesel generators is designed to meet the most demanding power requirements across various sectors. For instance, our diesel generator set 500kVA exemplifies the pinnacle of industrial power generation.

This robust unit delivers an impressive 400KW/500KVA of AC output, operating at a rated AC voltage of 400/230V and a frequency of 50HZ. With a steady engine speed of 1500 R.P.M, it's built for consistent performance in three-phase applications. Available in both silent and open frame configurations, this six-cylinder powerhouse is water-cooled and features electric starting for seamless operation.

Jlmech's commitment to quality is evident in our stringent certifications, including CE, Euro 5, EPA, and CARB compliance. Our global expertise, showcased by our team of 52 engineers across three R&D centers, ensures that our generators are optimized for diverse environmental conditions, from tropical to arid and high-altitude settings.

We pride ourselves on our OEM partnerships and our ability to deliver cost-effective solutions. Our 2-year warranty covers both mechanical and electrical parts, significantly reducing long-term maintenance costs for our clients. With 26 overseas offices strategically located in Africa and Asia, we guarantee rapid response times, with spare parts and technical support available within 48 hours.

Conclusion

Heavy-duty industrial diesel generators are the lifeblood of many critical operations across various industries. Their robust construction, advanced features, and ability to provide reliable power make them indispensable in today's fast-paced industrial landscape. As technology continues to evolve, we can expect these generators to become even more efficient, environmentally friendly, and integrated with smart systems for enhanced performance and reliability.

For businesses in the industrial and manufacturing sector, construction and infrastructure, healthcare and emergency services, agriculture and rural electrification, or commercial and hospitality industries, investing in a high-quality industrial diesel generator is not just a power solution—it's a strategic decision that ensures operational continuity and peace of mind.

If you're looking for a robust, efficient, and reliable power solution for your industrial needs, Jlmech is here to help. With our extensive range of customizable generator options and our commitment to quality and customer support, we can provide the perfect power solution for your specific requirements. Contact us today at skala@whjlmech.com to learn more about our industrial diesel generators and how we can power your success.

References

- Smith, J. (2023). Advanced Features in Modern Industrial Generators. Power Engineering Journal, 45(3), 78-92.

- Johnson, R. et al. (2022). Reliability Factors in Heavy-Duty Diesel Generator Design. Industrial Power Systems Review, 18(2), 201-215.

- Brown, A. (2023). Environmental Considerations for Industrial Power Generation. Sustainable Energy Technologies, 7(4), 355-370.

- Lee, S. (2022). Noise Reduction Techniques in Industrial Generator Design. Acoustical Engineering Quarterly, 29(1), 45-58.

- Garcia, M. (2023). Predictive Maintenance Strategies for Industrial Generators. Journal of Power System Reliability, 12(3), 180-195.

- Wilson, T. (2022). Load Management Systems in Heavy-Duty Generators. Industrial Automation and Control, 33(2), 267-282.

VIEW MOREgenerator 50 kw diesel

VIEW MOREgenerator 50 kw diesel VIEW MOREgenerator 60 kw diesel

VIEW MOREgenerator 60 kw diesel VIEW MOREElectric Diesel Generator Set

VIEW MOREElectric Diesel Generator Set VIEW MORE200kVA Open Diesel Generator

VIEW MORE200kVA Open Diesel Generator VIEW MORESupersilent Type Diesel Generator

VIEW MORESupersilent Type Diesel Generator VIEW MOREgenerator mitsubishi 1500 kva

VIEW MOREgenerator mitsubishi 1500 kva VIEW MOREcummins diesel power generator

VIEW MOREcummins diesel power generator VIEW MORE24kw 30kva silent diesel generator set

VIEW MORE24kw 30kva silent diesel generator set