Is it safe to run a generator continuously?

This is one of the most critical questions for businesses considering generator power for their primary operations. The straightforward answer is a resounding yes - provided you're using equipment specifically engineered for this demanding application. While attempting to run a standard standby generator continuously poses significant safety risks and will inevitably lead to premature failure, operating a properly specified continuous generator is not only safe but represents standard practice across numerous industries worldwide. The distinction lies not in the concept of continuous operation itself, but in having the right equipment, maintenance protocols, and operational awareness.

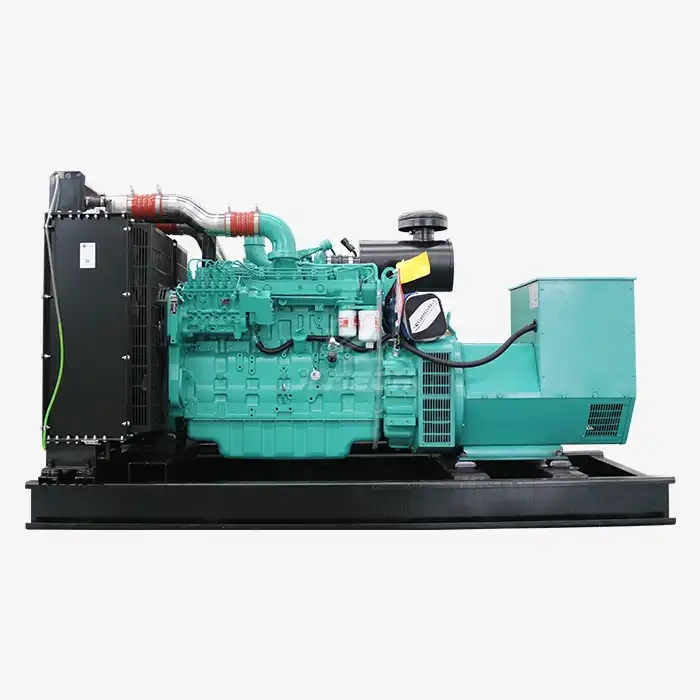

Understanding this distinction is crucial for ensuring both operational safety and equipment longevity. An industrial-grade continuous generator is fundamentally different from its standby counterparts, designed from the ground up with reinforced components, enhanced cooling capabilities, and durability features that make around-the-clock operation not just possible, but reliable and safe.

Proper Equipment Design

Safety in continuous operation begins with selecting the correct type of generator. This fundamental choice determines everything from performance reliability to operational safety and long-term viability.

Continuous Power Rating Certification:

True continuous generators carry specific ratings for unlimited operation at their designated capacity

These units undergo rigorous testing to validate their ability to handle constant thermal and mechanical stresses

Unlike standby generators designed for emergency use only, continuous-rated models are engineered specifically for 24/7 operation

Heavy-Duty Component Selection:

Reinforced engine blocks with strengthened cylinder walls and crankshafts

Oversized bearings and lubrication systems designed for constant operation

Enhanced cooling systems with larger radiators and more efficient heat dissipation

Heavy-duty alternators with superior insulation classes and robust construction

Engineering for Durability:

Every component in a proper continuous generator is selected based on endurance criteria rather than cost considerations

These units undergo comprehensive testing that simulates years of continuous operation before leaving the factory

The design philosophy focuses on reliability and safety under the most demanding operating conditions

Professional Maintenance Regimen

Continuous operation demands an equally continuous commitment to maintenance. A rigorous, well-documented maintenance schedule isn't merely recommended - it's absolutely essential for safe long-term operation.

Service Interval Adherence:

Follow manufacturer-recommended service intervals based strictly on operating hours

Maintain detailed service records tracking all maintenance activities and operational parameters

Implement a proactive maintenance strategy rather than waiting for issues to develop

Critical Maintenance Components:

Oil and Filtration System: More frequent changes than standby units, using specialized lubricants formulated for extended service

Cooling System Maintenance: Regular coolant analysis, system flushing, and radiator cleaning to prevent overheating

Air Intake System: Frequent filter inspection and replacement, especially in dusty environments

Fuel System Management: Regular filter changes, water separation, and tank maintenance to ensure clean fuel delivery

Electrical System Verification: Comprehensive testing of all electrical components, connections, and control systems

Professional Maintenance Standards:

While basic daily checks can be performed by operational staff, complex maintenance requires certified technicians

Professional maintenance ensures proper diagnosis of developing issues before they become serious problems

Factory-trained technicians possess the specific knowledge and tools necessary for maintaining continuous operation safety

Installation and Operating Environment

The safety of continuous operation depends heavily on proper installation and appropriate operating conditions. Even the best generator will underperform - or become unsafe - if installed incorrectly or operated in unsuitable environments.

Ventilation and Airflow Requirements:

Ensure adequate airflow for both engine combustion and cooling system efficiency

Poor ventilation leads to dangerous carbon monoxide accumulation and operational overheating

Follow manufacturer specifications for clearance distances and air intake requirements precisely

Exhaust System Safety:

Professional exhaust system installation is non-negotiable for continuous operation safety

Use high-temperature rated materials and proper supporting structures

Ensure exhaust pathways are clear and directed away from occupied spaces and air intakes

Foundation and Vibration Management:

Install on a level, vibration-dampening foundation designed for continuous operation

Proper foundation prevents structural stress and reduces wear on components

Consider professional vibration analysis for large installations to identify potential issues

Environmental Protection and Access:

Shelter units from extreme weather while maintaining adequate airflow

Ensure sufficient space around the generator for maintenance access and emergency procedures

Implement proper drainage and spill containment measures as required

Operational Monitoring and Safety Systems

Vigilant monitoring and robust safety systems provide the final layer of protection for continuous generator operation. Modern continuous generator installations incorporate multiple layers of safety and monitoring to ensure reliable operation.

Routine Operational Checks:

Implement scheduled visual inspections for leaks, unusual noises, or smoke

Train operational staff to recognize early warning signs of potential issues

Maintain detailed operational logs tracking key parameters and any anomalies

Performance Parameter Monitoring:

Continuously monitor oil pressure, coolant temperature, and operating voltage

Track fuel consumption rates and identify unusual patterns that might indicate problems

Monitor load profiles to ensure operation within designed parameters

Load Management Protocols:

Avoid sustained operation above the generator's continuous rating

Implement load sequencing for multiple generator installations

Use power management systems to optimize performance and prevent overload conditions

Integrated Safety Systems:

Modern continuous generator systems include comprehensive automatic shutdown features

Multiple redundant protection systems for low oil pressure, high temperature, and overspeed conditions

Regular testing of all safety systems to ensure proper operation when needed

Conclusion

Operating a generator continuously is not only safe but represents standard industrial practice when you begin with the right equipment, implement a disciplined maintenance program, ensure proper installation, and maintain vigilant operational monitoring. A true industrial continuous generator, properly specified and maintained, provides completely safe and reliable power for the most demanding applications. The key to safety lies in recognizing that continuous operation requires a different approach than emergency standby use - from equipment selection through daily operation.

Our engineering team specializes in helping clients implement safe, reliable continuous power solutions. We provide everything from initial assessment and equipment specification to ongoing maintenance support. For a comprehensive evaluation of your continuous power needs, contact our power systems specialists at skala@whjlmech.com.

References

International Organization for Standardization. (2018). Reciprocating internal combustion engine driven generating sets — Part 1: Application, ratings and performance (ISO 8528-1:2018).

Generator Manufacturers Association. (2021). Recommended Maintenance Practices for Continuous Power Generator Sets. GMA Technical Bulletin TB-204.

Anderson, P. (2020). Best Practices in Industrial Generator Maintenance and Safety. Power Systems Engineering Journal, 45(3), 112-128.

International Electrotechnical Commission. (2019). Rotating electrical machines - Rating and performance (IEC 60034-1:2019).

National Fire Protection Association. (2020). Standard for Emergency and Standby Power Systems (NFPA 110).

_1753350153132.webp)