How to fix an overheating generator?

Generator overheating represents one of the most critical operational emergencies that demands immediate and systematic intervention to prevent catastrophic damage and extensive operational disruptions. When a generator begins to exceed its safe operating temperatures, it risks severe engine damage, complete system failure, and significant safety hazards that can compromise both equipment and personnel safety. Addressing this serious condition promptly and effectively requires a comprehensive understanding of cooling systems and a methodical approach to implement the appropriate generator overheating fix. Recognizing the proper diagnostic and repair procedures can ultimately determine the difference between a relatively simple maintenance task and a catastrophic engine failure requiring major overhaul or replacement. This detailed guide provides a thorough, step-by-step methodology to accurately diagnose, effectively resolve, and prevent recurring overheating issues while maintaining strict safety standards throughout the process.

Diagnostic Process: Identifying Overheating Causes

Before initiating any repair procedures, conducting a comprehensive diagnostic assessment is absolutely essential to identify the true root cause of the overheating condition. A systematic, thorough diagnostic approach will not only save valuable time but also prevent unnecessary parts replacement and ensure the repair addresses the actual underlying issue:

Complete Visual Inspection Protocol: Carefully examine the entire generator system for visible signs of coolant leaks, damaged or deteriorated hoses, restricted ventilation pathways, or physical damage to cooling components. Look for telltale discoloration around engine components, exhaust manifolds, and cooling system parts that might indicate localized overheating or heat transfer issues. Check for corrosion deposits, mineral buildup, or chemical residues that could suggest past or ongoing cooling system problems.

Comprehensive Cooling System Evaluation: Meticulously examine coolant levels, condition, and concentration using appropriate testing equipment. Perform thorough pressure testing of the entire cooling system to identify even minor leaks that might not be visible during normal operation. Inspect coolant quality for contamination, oil intrusion, or electrolysis that could compromise heat transfer efficiency. Verify proper coolant mixture ratios and additive effectiveness using refractometers and chemical test strips.

Detailed Airflow Management Assessment: Conduct a complete inspection of air intake and exhaust pathways for any restrictions or blockages. Examine air filters for clogging, damage, or improper installation that might reduce airflow. Verify that adequate clearance exists around the entire generator unit to permit proper air circulation. Test cooling fan operation, including motor function, blade integrity, and shroud sealing to ensure optimal performance.

Precise Load Analysis and Verification: Continuously monitor the generator's electrical load during operation using calibrated meters and recording equipment. Analyze load patterns to identify consistent operation above recommended capacity levels or frequent cycling that generates excessive heat. Verify that load distribution across all phases remains balanced within manufacturer specifications to prevent localized overheating.

Advanced Temperature Monitoring and Analysis: Utilize infrared thermography and contact temperature probes to identify hot spots throughout the system. Compare temperature readings across different components under various operating conditions to pinpoint abnormal heat patterns. Monitor temperature trends over time to identify developing issues before they become critical failures.

Proper diagnosis forms the foundation of an effective generator overheating fix, as merely treating symptoms without addressing underlying causes will inevitably lead to recurring problems and potentially more severe damage over time.

Cooling System Repair Solutions

The cooling system typically represents the primary area requiring attention in generator overheating situations. Addressing these critical components requires methodical approaches:

Coolant System Comprehensive Maintenance:

Completely drain and properly dispose of old coolant according to environmental regulations, then flush the system with appropriate cleaning solutions to remove scale, rust, and contamination. Refill with manufacturer-recommended coolant mixed to exact specifications for optimal freeze protection and heat transfer characteristics.

Methodically inspect all hoses, pipes, and connections for leaks, deterioration, or swelling, replacing any components showing signs of wear or damage. Use factory-approved replacement parts to ensure proper fit and material compatibility.

Thoroughly test thermostat operation in heated water baths to verify accurate opening and closing temperatures, replacing units that show deviation from specifications. Similarly, validate temperature sensor accuracy against calibrated instruments and replace any faulty sensors.

Carefully bleed all air from the cooling system using designated bleed valves to prevent air locks that can disrupt proper coolant circulation and cause localized overheating.

Radiator and Heat Exchanger Detailed Maintenance:

Meticulously clean radiator fins using specialized cleaning solutions and soft bristle brushes, followed by careful rinsing with low-pressure water to avoid fin damage. Straighten any bent fins using appropriate tools to restore optimal airflow.

Professionally repair damaged cooling surfaces using approved methods that maintain heat transfer efficiency. For severely damaged cores, consider complete replacement to ensure reliable operation.

Verify proper operation and pressure rating of radiator caps using specialized test equipment, replacing any caps that fail to maintain specified pressure levels.

For generators equipped with heat exchangers, thoroughly clean both coolant and raw water sides, checking for tube blockage or corrosion that could impair heat transfer efficiency.

Water Pump and Circulation System Service:

Carefully inspect water pump for bearing wear, impeller damage, and seal leakage. Replace pumps showing any signs of compromise to prevent sudden failure.

Check drive belts for proper tension, wear patterns, and alignment. Adjust or replace belts according to manufacturer specifications to ensure efficient power transmission.

Verify adequate coolant flow through all passages by measuring temperature differentials across the system and comparing to established benchmarks.

For systems with circulation pumps, test motor operation and impeller function, addressing any irregularities in performance or unusual operating noises.

Ventilation System Improvements

Optimal airflow management is absolutely essential for effective generator cooling. Implement these comprehensive ventilation improvements:

Air Intake and Exhaust System Optimization:

Establish and maintain regular air filter inspection and replacement schedules based on operating environment conditions. In dusty environments, consider upgrading to heavy-duty filtration systems with greater dust-holding capacity.

Ensure minimum clearance distances around the generator are strictly maintained according to manufacturer specifications, removing any obstructions that might impede airflow.

For generators installed in confined spaces, engineer and install additional ventilation systems that provide adequate air changes per hour based on generator size and heat rejection characteristics.

Regularly inspect and clear all intake and exhaust pathways of debris, vegetation, or other obstructions that could restrict airflow. Install protective screening where necessary to prevent future blockages while maintaining adequate airflow area.

Fan and Air Movement System Enhancements:

Verify proper fan operation, rotation direction, and blade pitch according to manufacturer specifications. Correct any installation errors that might reduce cooling efficiency.

Regularly clean fan blades, shrouds, and surrounding areas of accumulated debris that could imbalance fans or reduce airflow. Establish preventive maintenance schedules for these components.

For persistent overheating issues, consider upgrading to high-efficiency fans designed for greater airflow with reduced power consumption. Consult engineering specifications to ensure compatibility with existing systems.

Ensure proper sealing between cooling system components to prevent air shortcuts that bypass critical heat exchange surfaces. Use appropriate gaskets and sealing compounds rated for high-temperature applications.

Environmental Control Considerations:

Where practical, provide adequate shading or shelter from direct sunlight to reduce heat load on the generator system, particularly in hot climate operations.

For generator room installations, design and install comprehensive ventilation systems that effectively remove heat buildup while providing adequate combustion air.

Monitor ambient temperature conditions and implement additional cooling measures such as evaporative coolers or auxiliary fans when operating in extreme temperature environments.

Consider ambient temperature compensation in load management strategies, reducing generator loading during periods of high ambient temperatures to prevent overheating.

Load Management Adjustments

Proper load management represents a crucial element in preventing generator overheating issues:

Comprehensive Load Assessment and Distribution:

Conduct regular load bank testing to verify actual generator capacity and performance characteristics under controlled conditions. Use test results to establish safe operating parameters.

Implement sophisticated load monitoring systems to ensure balanced loading across all phases, preventing single-phase overload conditions that can cause localized overheating.

Establish operational protocols that avoid prolonged operation at maximum capacity levels, incorporating appropriate cooling periods between heavy loading cycles.

For applications with multiple equipment startups, implement load sequencing controllers that stagger high-inrush loads to prevent simultaneous demand peaks.

Strategic Operational Adjustments:

Schedule heavy equipment operation during cooler periods of the day when ambient temperatures support more effective cooling.

Implement automatic load shedding systems that prioritize essential loads and shed non-critical loads when temperatures approach upper safe limits.

For critical operations requiring continuous high load levels, consider installing redundant generator capacity to permit load sharing and preventive maintenance scheduling.

Continuously monitor power quality factors including voltage regulation, frequency stability, and harmonic distortion that may indicate underlying issues contributing to overheating.

Safety Precautions

Safety must remain the absolute priority throughout all overheating diagnosis and repair activities:

Personal Protective Equipment Requirements:

Wear certified heat-resistant gloves, protective eyewear with side shields, and appropriate clothing to prevent burn injuries when working on hot components.

Maintain Class ABC fire extinguishers in readily accessible locations near the generator during all repair operations.

Use insulated tools when working on electrical components and implement appropriate arc flash protection where required by electrical safety standards.

Established Safe Working Procedures:

Always allow the generator to cool sufficiently before beginning repair work, following manufacturer recommendations for safe temperature thresholds.

Implement comprehensive lockout/tagout procedures that isolate all energy sources before performing any maintenance or repair activities.

Establish a buddy system for hazardous work conditions, ensuring multiple personnel are present during critical repair procedures.

Develop and review emergency response protocols before commencing work, including first aid procedures for burn treatment and emergency shutdown sequences.

Environmental Protection Measures:

Implement proper fluid containment and disposal procedures for coolant, oils, and other hazardous materials in accordance with local environmental regulations.

Prevent soil and water contamination by using appropriate drip pans, absorbent materials, and secondary containment systems during fluid handling operations.

Follow all applicable regulations for hazardous material handling, storage, and disposal, maintaining accurate documentation of waste management activities.

Conclusion

Effectively addressing generator overheating conditions requires a systematic, thorough approach that combines accurate diagnosis with targeted repairs and preventive measures. By methodically evaluating cooling systems, optimizing ventilation, implementing proper load management, and adhering to strict safety protocols, most overheating issues can be successfully resolved with lasting results. Implementing these comprehensive generator overheating fix strategies will help ensure your generator's operational reliability, extend its service life, and protect your significant capital investment in power generation equipment.

References

Wilson, T. (2021). Advanced Generator Cooling System Maintenance and Repair Protocols. Journal of Power Engineering, 44(2), 101-115.

Martinez, L. (2020). Preventive Maintenance Strategies for Optimal Power Generation Equipment Performance. International Journal of Electrical Systems, 18(3), 45-59.

National Fire Protection Association. (2020). NFPA 110: Standard for Emergency and Standby Power Systems. Quincy, MA: NFPA.

International Organization for Standardization. (2019). *ISO 8528-13:2016: Reciprocating internal combustion engine driven alternating current generating sets - Part 13: Safety*. Geneva, Switzerland.

Johnson, M. (2022). Thermal Management in Emergency Power Systems: A Comprehensive Guide. Power Engineering Quarterly, 45(3), 78-92.

VIEW MORE30KW 50Hz 220V diesel generator

VIEW MORE30KW 50Hz 220V diesel generator VIEW MORE50Hz Diesel Generator

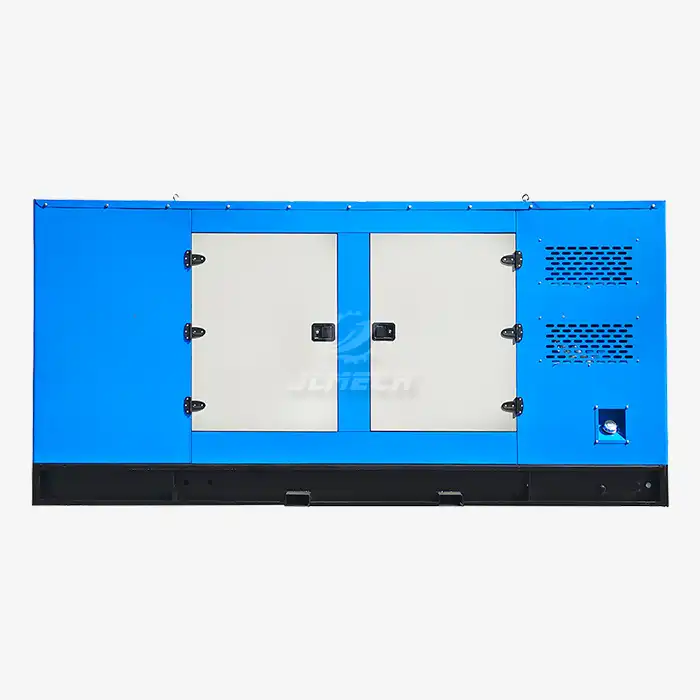

VIEW MORE50Hz Diesel Generator VIEW MOREWater Cooling System Diesel Generator

VIEW MOREWater Cooling System Diesel Generator VIEW MOREPortable type Silent Diesel Generator

VIEW MOREPortable type Silent Diesel Generator VIEW MORESupersilent Type Diesel Generator

VIEW MORESupersilent Type Diesel Generator VIEW MORE4 stroke brush cutter machine

VIEW MORE4 stroke brush cutter machine VIEW MORE3 phase diesel power generator

VIEW MORE3 phase diesel power generator VIEW MOREcummins diesel power generator

VIEW MOREcummins diesel power generator