How often should you change the oil in a diesel generator?

A diesel generator checklist is a systematic tool that outlines critical inspection and maintenance tasks. It serves as a proactive measure to ensure operational reliability, prevent unexpected failures, and extend equipment lifespan. While many seek a one-size-fits-all checklist, the reality is that an effective checklist must align with your specific diesel generator maintenance schedule, which varies based on model, usage, and environment. A well-structured checklist transforms abstract maintenance guidelines into actionable steps, providing clarity and consistency for operators and technicians.

Factors Influencing Oil Change Intervals

Determining the optimal oil change frequency involves evaluating several key factors. The single most important factor is the manufacturer’s recommendations outlined in your official diesel generator maintenance schedule. Engine designers specify intervals based on rigorous testing, accounting for internal clearances, materials, and expected operating conditions. Ignoring these guidelines can void warranties and risk costly damage.

Other critical factors include:

Operational Load: Generators running under heavy load (>70% capacity) generate more heat and contaminants, necessitating more frequent changes. Conversely, units frequently operating under light loads may develop fuel dilution and require shorter intervals.

Environmental Conditions: Dusty, humid, or extremely hot environments accelerate oil degradation.

Fuel Quality: Poor-quality or contaminated fuel can introduce harmful particles and moisture into the oil.

Run Hours vs. Time: Even with minimal use, oil should be changed at least annually to prevent acidity buildup and moisture absorption.

Your diesel generator maintenance schedule should integrate these variables to determine the correct interval.

General Guidelines and Recommended Intervals

While always deferring to your manufacturer’s manual, these general guidelines can serve as a reference point:

Standby Generators: Used for emergency power during outages: Change oil every 100-200 hours of operation or annually.

Prime Power Generators: Used as a primary power source: Change oil every 250-500 hours of operation.

Continuous/Heavy-Duty Applications: Subject to extreme loads or harsh conditions: Change oil every 100-150 hours.

These intervals highlight why a customized diesel generator maintenance schedule is essential—it harmonizes manufacturer specs with your real-world usage.

Signs That Immediate Oil Change is Needed

Even before a scheduled service, watch for these signs indicating urgent need for an oil change:

Dark, Murky Oil: Fresh oil is amber and translucent. Black, gritty oil is saturated with contaminants.

Fuel Odor: A strong smell of diesel in the oil indicates fuel dilution, often from frequent low-load operation.

High Oil Consumption: Needing frequent top-offs between changes can signal internal leaks or burning.

Overheating: Degraded oil loses its ability to lubricate and cool, leading to elevated operating temperatures.

Warning Lights: Never ignore the engine oil pressure or check engine lights.

Regular oil analysis is the most accurate method to monitor condition and optimize your diesel generator maintenance schedule.

Basic Oil Change Procedure and Common Mistakes

A proper oil change involves more than just draining and refilling. Key steps include:

Run the generator to warm the oil (ensures complete drainage).

Turn off the engine and isolate it from all power sources.

Place a drain pan beneath the oil drain plug.

Remove the plug and allow oil to drain completely.

Replace the oil filter—this is critical, as a clogged filter can circulate contaminants.

Refill with the exact type and grade of oil specified by the manufacturer.

Start the engine and check for leaks, then verify oil level.

Common mistakes to avoid:

Reusing old oil filters.

Over- or under-tightening the drain plug or filter.

Using incorrect oil viscosity or API rating.

Not disposing of old oil and filters responsibly.

Failing to document the service in your maintenance log.

Conclusion

A disciplined approach to oil changes, guided by a professional diesel generator maintenance schedule, is one of the most effective ways to ensure reliability, maximize longevity, and protect your power investment. It turns reactive repairs into proactive care, saving significant time and money while preventing operational disruptions.

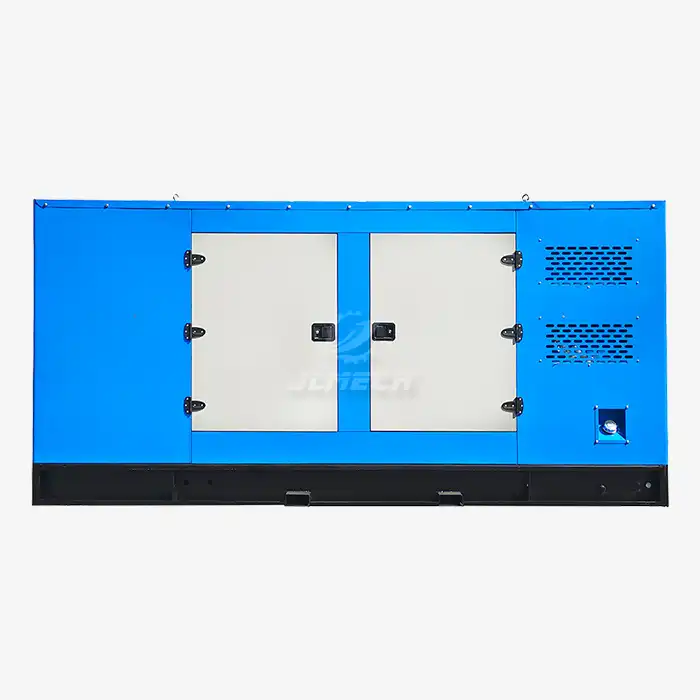

JLMECH possesses extensive expertise in power generation solutions and upholds an unwavering commitment to quality. We provide detailed maintenance guidance and high-performance generator systems built for resilience.

Need help optimizing your maintenance plan? Our expert team at JLMECH is here to assist you. Contact us today at skala@whjlmech.com to discuss your specific needs and discover our tailored power solutions and support services.

References

International Organization for Standardization. (2018). *ISO 8528-5:2018 Reciprocating internal combustion engine driven alternating current generating sets — Part 5: Generating sets*. Geneva, Switzerland.

Society of Automotive Engineers (SAE). (2019). SAE J300: Engine Oil Viscosity Classification. Warrendale, PA, USA.

National Fire Protection Association (NFPA). (2022). NFPA 110: Standard for Emergency and Standby Power Systems. Quincy, MA, USA.

VIEW MOREStandby generator 20kVA

VIEW MOREStandby generator 20kVA VIEW MORECustomized 100KW diesel generator

VIEW MORECustomized 100KW diesel generator VIEW MORE50kVA Silent Diesel Generator

VIEW MORE50kVA Silent Diesel Generator VIEW MOREDirect injector diesel engine generator

VIEW MOREDirect injector diesel engine generator VIEW MOREMaximum power 3000KW generator

VIEW MOREMaximum power 3000KW generator VIEW MOREperkins 100kva diesel generator

VIEW MOREperkins 100kva diesel generator VIEW MORE300kva diesel generator perkins ats

VIEW MORE300kva diesel generator perkins ats VIEW MOREgenerator engine diesel

VIEW MOREgenerator engine diesel