How a Diesel Fuel Injection Valve Works (And Why It Matters)

Think of a diesel engine as a powerful, self-contained team. The piston provides the muscle, the crankshaft converts the motion, and the fuel provides the energy. But there is one critical, unsung hero that manages this energy with split-second, microscopic precision: the Diesel Fuel Injection Valve. Often called an injector, this component is the ultimate gatekeeper. Its job is not just to spray fuel; it is to atomize diesel into a fine mist at exactly the right nanosecond, at the perfect pressure, and in a precise pattern inside the combustion chamber. Getting this wrong means wasted fuel, lost power, and a damaged engine. Getting it right is the secret to the legendary efficiency, power, and longevity of a modern diesel engine. Understanding how this vital part works will help you appreciate the engineering inside your equipment and recognize the importance of its maintenance.

The Heart of Efficiency: More Than Just a Spray Nozzle

Why does such a small part deserve so much attention? Because in a diesel engine, fuel and air mix inside the cylinder under immense pressure and heat. Unlike a gasoline engine that uses a spark plug, diesel engines rely on compression ignition—air is squeezed until it's extremely hot, then fuel is injected to ignite instantly.

The Diesel Fuel Injection Valve is responsible for this crucial injection. If it sprays too early, too late, in a poor pattern, or with droplets that are too large, combustion becomes inefficient. This leads to:

Loss of Power: Incomplete burning means you don't get the full energy from your fuel.

Poor Fuel Economy: You burn more diesel for the same amount of work.

Excessive Smoke: Unburned fuel exits as black or white smoke.

Engine Knock and Damage: Improper timing can cause violent pressure spikes.

In short, the performance of your entire engine hinges on the precision of this one component. A faulty Diesel Fuel Injection Valve doesn't just cause a minor hiccup; it can degrade the heart of your operation.

A Step-by-Step Look Inside the Injection Process

Let's break down the split-second operation of this precision instrument.

The High-Pressure Build-Up: The process begins at the fuel injection pump (or common rail system), which pressurizes diesel fuel to extremely high levels—anywhere from 15,000 to over 30,000 PSI. This high-pressure fuel line feeds directly to the inlet of the injector.

The Waiting Phase: Inside the injector, the pressurized fuel pushes against a needle valve, held tightly shut by a powerful spring. At this moment, the valve is sealed, and no fuel enters the cylinder.

The Electronic Command: The engine control unit (ECU), the brain of the engine, calculates the exact moment for injection based on load, speed, and temperature. It sends a brief electrical signal to the solenoid or piezoelectric actuator on top of the injector.

The Precision Movement: This electrical signal activates the actuator, which lifts the needle valve against the spring tension. This is the critical opening action.

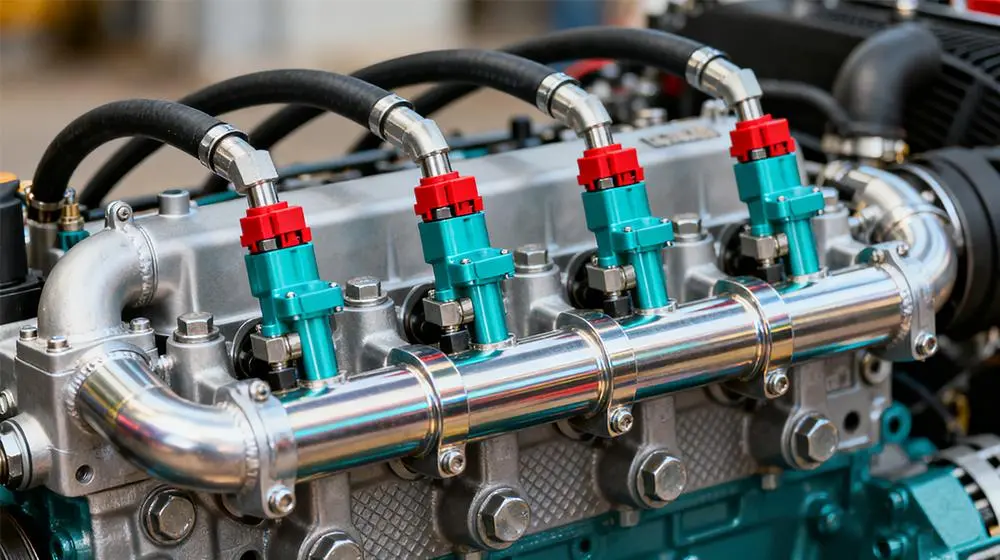

The Atomized Spray: The instant the needle valve lifts, the intensely pressurized fuel erupts through precisely machined holes in the injector tip (the nozzle). These holes are engineered to create a perfect cloud of atomized fuel—a fine mist that mixes thoroughly with the hot compressed air in the cylinder for complete, clean combustion.

The Clean Shut-Off: The electronic signal stops, the actuator deactivates, and the powerful spring slams the needle valve shut instantly. This provides a sharp, clean end to the injection event, preventing any dribbling of fuel.

This entire cycle happens in milliseconds, repeating thousands of times per minute. The precision of the Diesel Fuel Injection Valve in timing, duration, and spray pattern is what defines modern diesel efficiency.

The Visible Difference: A Healthy vs. A Failing Injector

You don't need to be an engineer to spot the signs of a problem.

A Healthy Injector means: Easy starting, smooth engine idle, full power output, clean exhaust (no smoke), and optimal fuel consumption.

A Failing Injector often causes: Hard starting, rough idle or engine misfire, noticeable loss of power, excessive black or blue smoke from the exhaust, a strong smell of unburned diesel, and a sudden increase in fuel usage.

Types of Injection Valves: From Mechanical to Common Rail

Technology has evolved significantly:

Mechanical Injectors: Older systems where a mechanical pump controlled timing and pressure. Less precise, but robust.

Electronic Unit Injectors (EUI): Combine the pump and injector into one unit per cylinder, controlled electronically for better precision.

Common Rail Injectors (CRI): The modern standard. A single high-pressure "common rail" supplies all injectors with constant, ultra-high-pressure fuel. The ECU controls each Diesel Fuel Injection Valve independently with extreme precision, allowing for multiple injection events per cycle (e.g., a small pilot injection for quietness before the main injection). This delivers maximum power with minimal noise and emissions.

Conclusion

The Diesel Fuel Injection Valve is a masterpiece of precision engineering, far more than a simple part. It is the critical director of your engine's performance, efficiency, and health. Its ability to manage fuel with microscopic accuracy is what separates a smooth, powerful, and economical engine from a troubled one.

Proper maintenance, including using clean, high-quality fuel and following recommended service intervals, is essential to protect this vital investment. When performance issues arise, the injectors are often the first place skilled technicians look.

If you are experiencing symptoms of injector trouble or want to ensure your diesel generator's fuel system is operating at peak performance, our technical team can help. We provide expert diagnostics, genuine replacement parts, and maintenance services for all major injector systems.

Contact us at skala@whjlmech.com for support in keeping your diesel power running cleanly and efficiently.

References

- Bosch. (2018). Diesel-Engine Management (5th ed.). Robert Bosch GmbH.

- Dennehy, P. (2020). Fuel Injection Systems: Principles and Diagnostics. Automotive Engineering International, 128(4), 34-39.

- Delphi Technologies. (2021). Common Rail Fuel Injection: A Technical Overview. Delphi Product & Service Solutions.

- Society of Automotive Engineers (SAE). (2019). SAE J2962: Guidelines for Diesel Fuel Injection System Testing. SAE International.

VIEW MORERemote area diesel unit

VIEW MORERemote area diesel unit VIEW MOREWeatherproof diesel generator

VIEW MOREWeatherproof diesel generator VIEW MORE300KW Mobile Generator Set for Mining Engineering

VIEW MORE300KW Mobile Generator Set for Mining Engineering VIEW MOREMobile Type Diesel Generator

VIEW MOREMobile Type Diesel Generator VIEW MORE50kVA Silent Diesel Generator

VIEW MORE50kVA Silent Diesel Generator VIEW MOREGarden diesel generator

VIEW MOREGarden diesel generator VIEW MOREelectric powered hedge trimmer

VIEW MOREelectric powered hedge trimmer VIEW MORE35kva cummins diesel generator with silent enclosure

VIEW MORE35kva cummins diesel generator with silent enclosure