Can I run a generator in an enclosed space?

For businesses and industries relying on diesel generators, this is one of the most critical safety questions you can ask. The short and definitive answer is no—you should never run a standard diesel generator in an enclosed space without proper engineering controls. Doing so creates immediate and severe risks to human life, equipment, and property. However, with specialized design and safety systems, it is possible to safely operate an enclosed diesel generator unit. This article explains the critical differences between a dangerous improvisation and a professionally engineered solution, guiding you toward safe and compliant power generation.

Understanding the Dangers

Running a standard generator indoors or in a poorly ventilated enclosure poses two primary, life-threatening hazards:

Carbon Monoxide (CO) Poisoning: Generators produce large amounts of carbon monoxide, an odorless and colorless gas. In an enclosed space, it can rapidly reach lethal concentrations, causing unconsciousness and death within minutes. NFPA 37 requires generators to be positioned to prevent exhaust gases from entering buildings through openings like windows and doors .

Fire and Explosion Risk: A generator presents multiple ignition sources. Hot exhaust components can ignite flammable materials , and a fuel leak could lead to a fire or explosion. The engine's air intake must also have unrestricted access to clean, cool air for proper combustion and cooling; restricting it can cause the engine to overheat and fail.

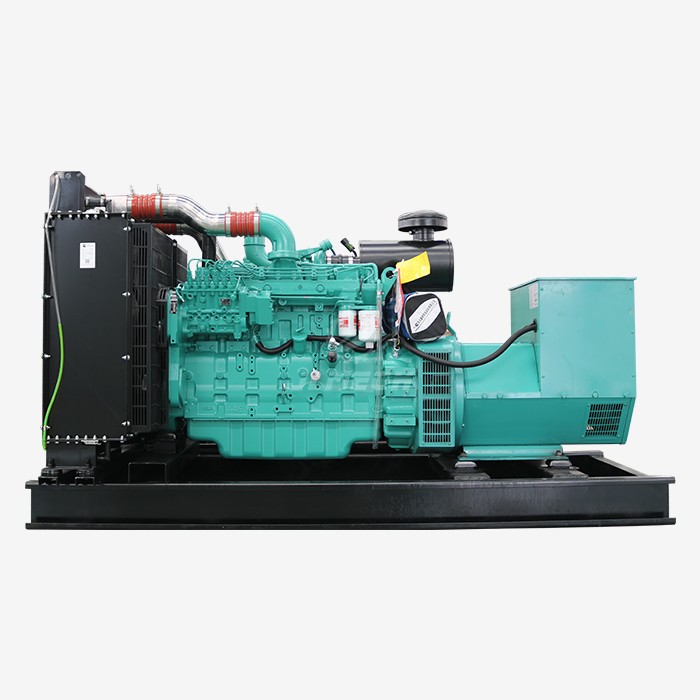

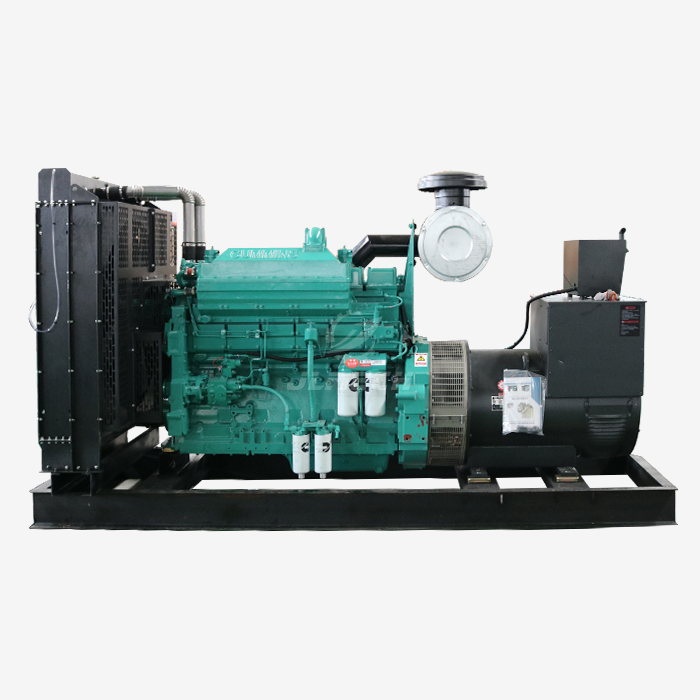

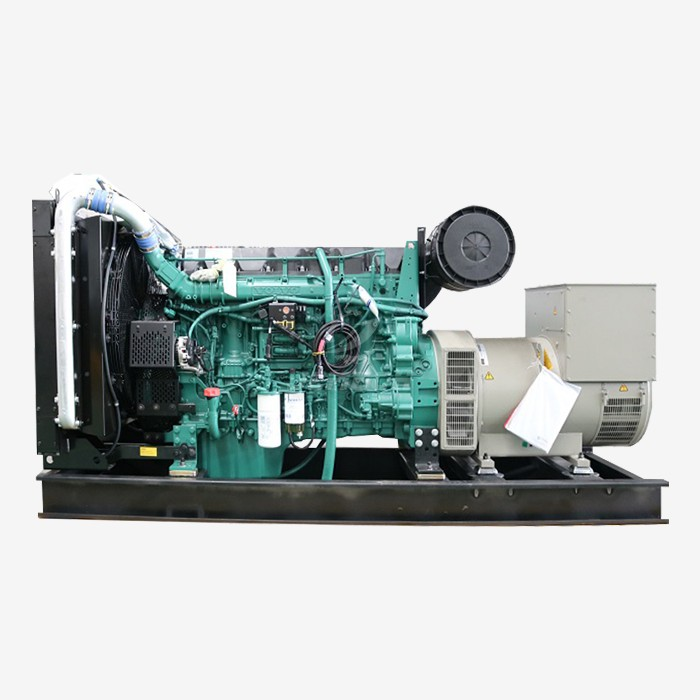

What is a Safely Enclosed Diesel Generator?

A safely enclosed diesel generator is not a standard generator placed in a random room. It refers to a fully integrated system where the generator is housed within a structure or enclosure specifically designed to mitigate all associated risks. This involves:

Professional Engineering: The enclosure is designed with integral ventilation, exhaust, fire protection, and cooling systems.

Compliance with Codes: The installation adheres to strict national and international standards, such as NFPA 37 for stationary combustion engines and relevant electrical codes like NFPA 70 (NEC).

Purpose-Built Components: It uses components like industrial-grade mufflers, correctly sized ventilation ducts, and fire-rated construction materials where necessary.

Essential Engineering Requirements

Creating a safe enclosed diesel generator setup requires addressing several non-negotiable engineering challenges:

Ventilation and Airflow: This is the system's lifeline. The enclosure must have a dedicated and correctly sized air intake and exhaust system. This system must provide sufficient cool, fresh air for both engine combustion and radiator cooling, while simultaneously removing hot air from the enclosure to prevent overheating. The ventilation design must also manage the risk of unburnt gas ignition in the exhaust system under fault conditions.

Exhaust System Management: The engine exhaust must be routed outside via a permanently installed, heat-resistant piping system. This often includes a high-quality muffler to reduce noise. The exhaust termination point must be located safely away from air intakes, windows, or any openings where gases could re-enter a building.

Heat Dissipation: Generators produce significant waste heat. The enclosure design must manage this thermal load to prevent damage to the generator and the enclosure itself. This typically involves coordinating the generator's radiator fan with the designed ventilation pathway.

Fire Protection: The installation must include fire protection measures. This can involve constructing the enclosure with non-combustible materials, providing a non-combustible surface like concrete for the generator to sit on, and installing automatic fire suppression systems as required by code.

Compliance and Safety Standards

Safely enclosing a generator is governed by a framework of codes and standards designed to protect life and property. Key among them are:

NFPA 37, Standard for the Installation and Use of Stationary Combustion Engines: This is a core standard, covering installation requirements, clearances from combustibles, and fuel supply safety.

NFPA 110, Standard for Emergency and Standby Power Systems: This defines requirements for the performance, installation, and maintenance of emergency power supply systems (EPSS).

Local Building and Electrical Codes: These adopt standards like the National Electrical Code (NEC) and have additional requirements for fuel storage, fire ratings, and permits, as seen in checklists from authorities like the San Francisco Fire Department.

Other International Standards: Depending on the location and application, other standards may apply, such as SS 535:2018 in Singapore or IEC/IEEE 63332-387:2024 for nuclear facilities.

Professional Installation vs. DIY Risks

This is not a do-it-yourself project. The risks of improper installation are simply too high.

Professional Installation ensures that the complex integration of structural, mechanical, and electrical systems is done correctly. A licensed professional will design to meet all applicable codes, obtain necessary permits, and validate that the system is safe and functional.

DIY Attempts carry an extreme risk of creating an unseen hazard. Mistakes in ventilation calculation, exhaust routing, or electrical wiring can lead to carbon monoxide poisoning, fire, engine failure, and voided warranties. The potential cost of a failure—in human life or property destruction—dwarfs the initial cost of a professional installation.

Conclusion

So, can you run a generator in an enclosed space? The answer is clear: only if it is a professionally engineered enclosed diesel generator system designed and installed in full compliance with all relevant safety codes and standards. Never attempt to run a standard portable or standby generator inside a building, garage, or other enclosed area without proper ventilation and safety systems. The safe path involves recognizing the serious hazards and partnering with experts to implement a correct and reliable solution.

Our expert team can help you select the most suitable enclosed diesel generator for your specific needs. Please send an email to skala@whjlmech.com to learn about our customized products and services designed for your company's unique power requirements.

References

IEC/IEEE 63332-387:2024. (2024). Nuclear facilities - Electrical power systems: Diesel generator units applied as standby power sources. International Electrotechnical Commission.

Captiva Island Fire Control District. (n.d.). Generator Safety Concerns.

U.S. Department of Energy. (n.d.). *CX-020900: MFC-787 Equipment Enclosure*.

Risk analysis of unburnt gas ignition in an exhaust system connected to a confined and mechanically ventilated enclosure fire. (2017). Fire Safety Journal, 91, 291-302.

Patel, D., et al. (2013). HIGH ALTITUDE, HIGH VOLTAGE TERMINAL BLOCK ASSEMBLY. U.S. Patent No. US20130036602A1.

SS 535:2018. (2018). Code of practice for installation, operation, maintenance, performance and construction. Singapore Standards.

San Francisco Fire Department. (n.d.). *2.07 Permit Application Checklist for Diesel Generators, Fuel-Oil Systems, Diesel Fire Pumps, and Fuel Tanks Serving Generators and Fire Pumps*.

NFPA 37-2018. (2018). Standard for the Installation and Use of Stationary Combustion Engines and Gas Turbines. National Fire Protection Association.

Electronic Code of Federal Regulations (eCFR). (2017). *14 CFR Part 29 Subpart E - Exhaust System*.