Are Diesel Generators Always Noisy? Debunking the Myth.

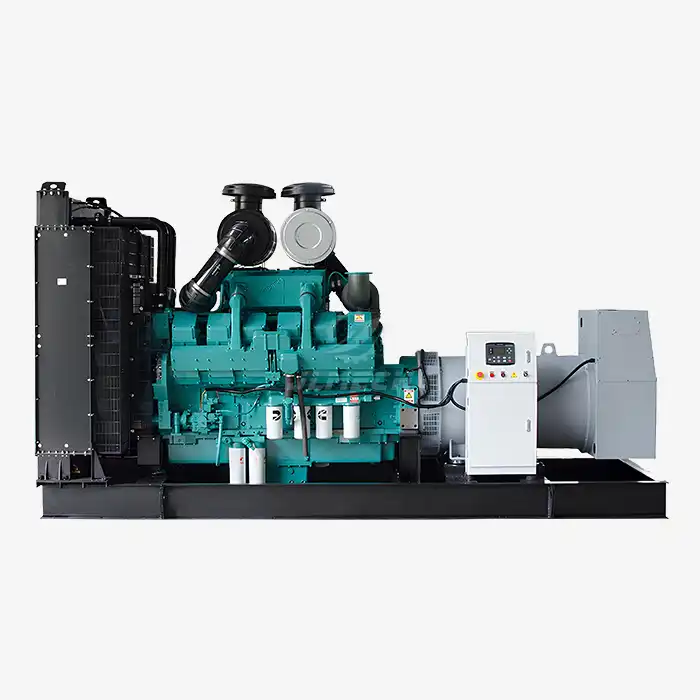

The image of a loud, rumbling diesel generator is firmly planted in the public mind. For many, the very thought of a generator conjures up a familiar chorus of complaints about the noise. This perception often leads to hesitation when considering a diesel generator for applications where peace and quiet are valued—be it a residential area, a hospital, a hotel, or an outdoor event. However, the question remains: are diesel generators inherently noisy? The reality is that modern engineering has dramatically transformed the landscape of diesel generator noise control. While traditional, unregulated models can indeed be loud, advancements in acoustic science have given rise to a new generation of generators that are anything but. This article will dismantle the common myth, explore the sources of sound, and reveal the sophisticated technologies that make quiet, reliable power a reality today.

The Origins of the Noise

To effectively control noise, one must first understand where it comes from. A diesel generator produces sound from several key sources, each requiring a specific approach to mitigation. The primary contributors to diesel generator noise are:

Engine Mechanical Noise: This is the sound produced by the rapid combustion within the cylinders and the movement of internal parts like pistons, valves, and the crankshaft. It is a dominant source of mid-to-high-frequency noise.

Exhaust Noise: The high-pressure gases released from the engine cylinders create a powerful pulsating flow out of the exhaust system. This is often one of the loudest noise sources if left untreated.

Cooling Fan Noise: To maintain a safe operating temperature, a large cooling fan operates continuously, generating significant aerodynamic noise as it moves air.

Induction Noise: The engine's air intake system produces noise as air is rapidly drawn in for the combustion process.

Generator (Alternator) Noise: The electromagnetic forces within the generator itself, combined with the cooling fan on its shaft, produce a characteristic high-frequency hum.

Research on a 40kW unit, for instance, successfully identified and targeted these specific noise sources, leading to a significant reduction in overall sound levels .

Modern Noise Control Technologies

The "loud generator" stereotype is being dismantled by a suite of advanced noise control technologies. Modern "silent" or "super-silent" generators are not just basic units in a box; they are meticulously engineered systems. Key innovations include:

Advanced Enclosures: Generators are housed in cabins made from steel or aluminum composite panels filled with high-density sound-absorbing materials like rock wool or foam . These enclosures are designed to contain and dampen sound effectively.

Sophisticated Mufflers: High-performance exhaust silencers, or mufflers, are critical for tackling low-frequency exhaust noise. Their internal baffles and chambers are designed to disrupt and absorb sound waves before they can escape.

Vibration Isolation: The engine and alternator are mounted on specially designed rubber or spring isolators. This prevents structure-borne vibration from being transmitted to the frame and the surrounding environment, a key step in reducing radiated noise .

Optimized Cooling with Acoustic Baffles: Instead of an open design, quiet generators use Z-shaped or labyrinthine air intake and exhaust ducts lined with acoustic louvers . This allows essential airflow for cooling while trapping and absorbing noise, preventing it from escaping directly to the outside.

Passive vs. Active Noise Control

The battle against generator noise is fought on two fronts: passive and active control. Most commercial silent generators rely on robust passive methods, which form the foundation of noise reduction.

Passive Noise Control: This refers to the use of physical materials and structures to block, absorb, or dampen sound. This includes all the technologies mentioned above—enclosures, mufflers, vibration isolators, and acoustic baffles. The design of a "double-layer air duct ultra-quiet power supply" is a prime example, achieving a remarkable noise level of less than 65 dB(A) at 7 meters through superior passive design .

Active Noise Control (ANC): This is a more advanced, electronic approach. ANC systems use microphones to pick up the low-frequency noise, a digital processor to analyze it, and speakers to generate an "anti-noise" signal that is the exact opposite (180 degrees out of phase). When these two signals meet, they cancel each other out. This technology has been successfully applied in luxury yachts, achieving over 5 dB of broadband attenuation and up to a 23% reduction in perceived loudness for generator noise .

Quantifying the Quiet: Noise Level Benchmarks

So, how quiet is "quiet"? The industry uses the decibel (dB(A)) scale to measure sound pressure levels. To put it in perspective, here are some common benchmarks:

Normal Conversation: ~60 dB(A)

Super Silent Generators: Some advanced designs, such as those featuring double-layer air ducts, can achieve noise levels as low as 65 dB(A) at 7 meters during no-load operation .

Standard Silent Generators: Typically operate between 70-75 dB(A) at 7 meters . Research on a 10kW unit achieved around 70 dB(A) at 3 meters through comprehensive vibration and noise treatment .

Unenclosed Industrial Generator: Can easily exceed 100 dB(A) at close range.

These figures demonstrate that a modern quiet generator can be a good neighbor, operating at sound levels comparable to everyday activities.

The Critical Balance: Noise Control vs. Ventilation

One of the biggest engineering challenges in creating a quiet generator is managing heat. A fully sealed enclosure would be very quiet but would cause the engine to overheat rapidly. Therefore, effective diesel generator noise control is a delicate balancing act between acoustics and thermodynamics.

Engineers use computational fluid dynamics (CFD) software to model and optimize airflow within the enclosure . The goal is to design intake and exhaust paths that provide maximum cooling with minimal acoustic leakage. Solutions like the Z-curved air ducts and specialized heat dissipation systems that transfer heat from inside the enclosure to external radiators via heat pipes are brilliant solutions to this very problem, ensuring full power output is maintained without compromising on noise levels.

Choosing the Right Generator for Your Noise Needs

When selecting a generator where noise is a concern, you must be an informed buyer. Simply asking for a "quiet generator" is not enough. Here is a practical checklist:

Ask for the Decibel Rating: Always request the official dB(A) measurement and confirm the distance at which it was taken (e.g., 7m or 3m).

Understand Load Conditions: Note that noise levels can be slightly higher under full electrical load compared to no-load conditions .

Prioritize a Quality Enclosure: Look for generators with robust, well-sealed enclosures filled with sound-absorbing material.

Consider the Installation Site: Factor in local noise regulations and the proximity to residential buildings, bedrooms, or other noise-sensitive areas. The perception of diesel generator noise is as important as the measurement itself.

Conclusion

The myth that diesel generators are always noisy is precisely that—a myth. While they are powerful machines that naturally generate sound, modern acoustic engineering has proven exceptionally effective at taming it. Through a combination of advanced enclosures, strategic vibration damping, high-efficiency mufflers, and intelligent cooling design, today's silent and super-silent diesel generators can provide reliable power without disturbing the peace. The challenge of diesel generator noise has been met with innovative and reliable solutions.

If you have specific noise level requirements or need a generator for a noise-sensitive environment, our engineering team is ready to help. We specialize in matching the right quiet power solution to your unique needs. For a personalized consultation, please contact us at skala@whjlmech.com.

References

Yan, T., Yang, L., Liu, J., Ouyang, X., Wu, X., & Bin, C. (2021). Noise Source Identification and Reduction of a 40 kW Diesel Generator Set. Noise and Vibration Control, 41(4), 276-281 .

Anonymous. (2018). Research on Ventilation, Heat Dissipation, and Vibration Noise of Silent Diesel Generator Sets. Anhui Polytechnic University .

World Ocean Engineering. Silent Environmental Power Station. Retrieved from .

Anonymous. (2020). Design of a Double-Layer Air Duct Ultra-Quiet Power Supply. 2020 China Communications Energy Conference Proceedings .

D. Pan, X. Qiu, & J. Yuan. (2016). Active noise control of a diesel generator in a luxury yacht. Applied Acoustics, 105, 209-214 .

Hong, S. (2018). A Low-Noise Diesel Generator Set. Chinese Utility Model Patent No. CN201820467652.X .

CCTV Finance. (2012). Saiwate Products Feature Efficient Noise Reduction and Environmental Protection. Retrieved from.