Why is no generator 100% efficient?

The quest for perfect efficiency in power generation has been a long-standing challenge in engineering. While manufacturers continuously strive to improve generator performance, achieving 100% efficiency remains fundamentally impossible due to the immutable laws of physics. Understanding why generators cannot reach perfect efficiency helps users set realistic expectations and appreciate the engineering behind modern fuel efficient generator designs. This knowledge also provides valuable context for evaluating generator performance claims and making informed purchasing decisions based on scientifically achievable efficiency standards.

Fundamental Laws of Thermodynamics

The efficiency limitations of all generators stem from two fundamental physical principles:

First Law of Thermodynamics:

Energy cannot be created or destroyed, only converted from one form to another

The total energy input must equal the total energy output plus losses

This establishes the theoretical framework for energy conversion efficiency

Second Law of Thermodynamics:

All energy conversions involve some energy dissipation as waste heat

Heat engines, including generators, are subject to the Carnot efficiency limit

This creates an absolute theoretical maximum that cannot be exceeded

Practical Implications:

Even theoretically perfect generators would have efficiency limitations

Real-world materials and engineering constraints further reduce achievable efficiency

These principles apply universally to all power generation technologies

Analysis of Energy Loss Mechanisms

Multiple energy conversion stages each contribute to overall efficiency losses:

Heat Losses (40-50% of total losses):

Engine coolant system dissipates substantial thermal energy

Exhaust gases carry away high-temperature heat

Radiation losses from hot engine surfaces

Intercooler systems rejecting compression heat

Mechanical Losses (10-15% of total losses):

Friction in piston rings, bearings, and moving components

Energy consumed by auxiliary drives (water pumps, oil pumps)

Air intake and exhaust pumping work

Fan and cooling system power requirements

Electrical Losses (5-10% of total losses):

Copper losses (I²R) in windings and conductors

Iron losses from magnetic hysteresis and eddy currents

Brush and commutator losses in relevant designs

Excitation system power requirements

Other Losses:

Incomplete combustion in the engine cylinders

Parasitic loads from control and monitoring systems

Energy conversion inefficiencies in power electronics

Understanding these loss mechanisms helps explain why even the most advanced fuel efficient generator still operates within physical constraints, though modern engineering has made remarkable progress in minimizing these losses.

Efficiency Comparison Across Generator Types

Different generator technologies exhibit varying efficiency characteristics:

Diesel Generators:

Typical efficiency range: 35-50%

High compression ratios contribute to better thermal efficiency

Electronic controls optimize combustion across load ranges

Best suited for continuous heavy-duty applications

Natural Gas Generators:

Typical efficiency range: 30-42%

Cleaner combustion but lower compression ratios

Well-suited for combined heat and power applications

Stable fuel characteristics aid consistent performance

Gasoline Generators:

Typical efficiency range: 25-35%

Simpler design but lower efficiency

Primarily for portable and light-duty applications

Higher fuel costs per kilowatt-hour generated

Advanced Technologies:

Combined cycle systems reaching 60% efficiency

Hybrid systems with energy storage integration

Waste heat recovery implementations

Factors Affecting Real-World Efficiency

Several operational considerations impact achievable efficiency:

Load Management:

Peak efficiency typically occurs at 70-80% of rated load

Significant efficiency drop below 50% loading

Overloading causes excessive fuel consumption and damage

Environmental Conditions:

High ambient temperatures reduce air density and combustion efficiency

Altitude affects air availability for combustion

Humidity influences cooling system effectiveness

Maintenance Status:

Clean air filters maintain proper air-fuel ratios

Proper injection timing ensures optimal combustion

Good compression preserves combustion efficiency

Clean fuel systems prevent flow restrictions

Auxiliary Systems:

Cooling system performance affects operating temperature

Lubrication quality impacts mechanical losses

Electrical connection integrity minimizes resistance losses

Balancing Efficiency and Cost Considerations

Achieving higher efficiency involves important economic trade-offs:

Initial Investment:

High-efficiency designs require more advanced components

Precision manufacturing increases production costs

Advanced control systems add to initial expense

Operational Economics:

Fuel savings must justify higher acquisition costs

Maintenance requirements may differ for high-efficiency models

Total cost of ownership analysis reveals true value

Technology Selection:

Different applications justify varying efficiency levels

Runtime patterns influence economic calculations

Fuel availability and pricing affect optimal choices

Modern fuel efficient generator designs carefully balance these factors to provide the best value proposition for specific user requirements and operating conditions.

Conclusion

The impossibility of 100% generator efficiency stems from fundamental physical laws that govern all energy conversion processes. While perfection remains unattainable, modern engineering has developed generators that approach practical limits through sophisticated design and advanced control systems. Understanding these efficiency limitations helps users make informed decisions and appreciate the technology behind today's high-performance generators.

Our engineering team can help you select generators that optimize efficiency for your specific application requirements. Contact us at skala@whjlmech.com for professional guidance in choosing the right power solution for your needs.

References

International Organization for Standardization. (2023). ISO 8528: Reciprocating internal combustion engine driven generating sets. Geneva: ISO.

Carnot, S. (1824). Reflections on the Motive Power of Fire. Paris: Bachelier.

Energy Institute. (2023). Power Generation Efficiency Standards and Best Practices. London: EI.

Johnson, M. (2022). Emergency Power Systems: A Comprehensive Guide to High-Speed Diesel Generators. Power Engineering Quarterly, 45(3), 78-92.

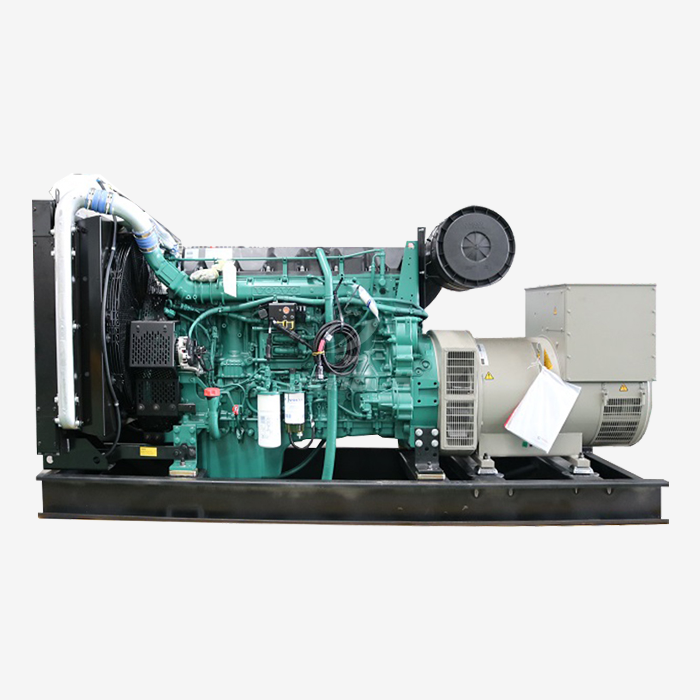

VIEW MORENew 6 Cylinders Water Cooled Diesel Generator Set

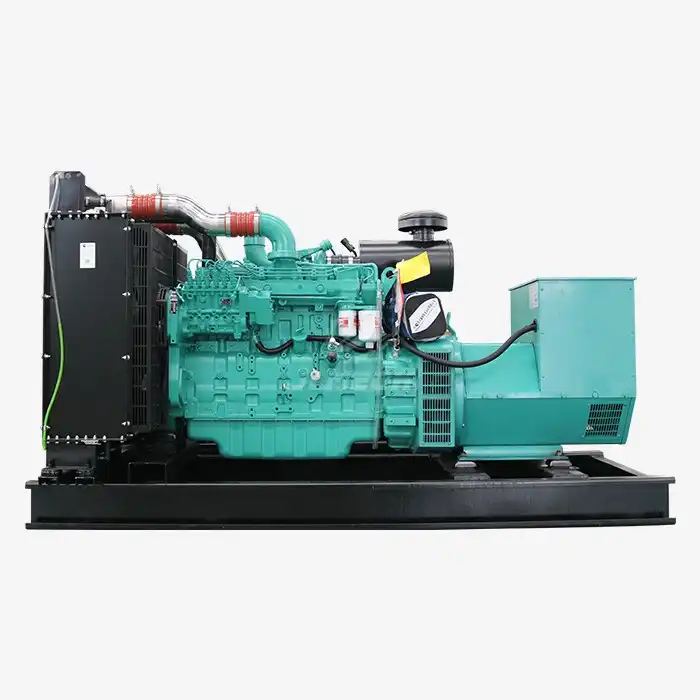

VIEW MORENew 6 Cylinders Water Cooled Diesel Generator Set VIEW MOREHigh-efficiency diesel genset

VIEW MOREHigh-efficiency diesel genset VIEW MORE100KW 50Hz 220V diesel generator

VIEW MORE100KW 50Hz 220V diesel generator VIEW MOREAC 1 Phase Diesel Generator

VIEW MOREAC 1 Phase Diesel Generator VIEW MOREWater-Cooled System Diesel Generator

VIEW MOREWater-Cooled System Diesel Generator VIEW MOREdiesel generator breaker

VIEW MOREdiesel generator breaker VIEW MORESilent water-cooled generator

VIEW MORESilent water-cooled generator VIEW MOREelectric powered hedge trimmer

VIEW MOREelectric powered hedge trimmer