The preference for 6-cylinder engines in diesel generators is rooted in their ability to deliver consistent power while maintaining mechanical harmony. This configuration allows for even distribution of forces within the engine, resulting in reduced wear and tear on components. Additionally, 6-cylinder engines can achieve higher power outputs without sacrificing efficiency, making them ideal for a wide range of applications. The balanced nature of a 6-cylinder layout also contributes to lower noise levels and improved overall performance, factors that are crucial in many industrial and commercial settings where diesel generators are deployed.

The engineering advantages of 6-cylinder diesel generator engines

Balanced Power Delivery

The 6-cylinder configuration in diesel generator engines offers significant engineering advantages that contribute to their widespread use. One of the primary benefits is the inherent balance in power delivery. With six cylinders arranged in a line or in a V-formation, the engine achieves a more even distribution of power strokes throughout the rotation cycle. This results in smoother operation and reduced vibration, which is crucial for the longevity of both the engine and the attached generator components.

Thermal Efficiency and Fuel Economy

Another key advantage of 6-cylinder diesel engines is their superior thermal efficiency. The layout allows for optimal combustion chamber design, facilitating more complete fuel burning and heat conversion to mechanical energy. This translates to improved fuel economy, a critical factor for operators of diesel generator sets who need to manage operational costs effectively. The enhanced efficiency also means that 6-cylinder engines can produce substantial power output while maintaining reasonable fuel consumption rates, making them suitable for a wide range of applications from standby power to continuous operation scenarios.

Adaptability and Scalability

Six-cylinder diesel engines offer excellent adaptability and scalability. Manufacturers can easily adjust the engine's displacement and power output by modifying cylinder bore and stroke without altering the fundamental design. This flexibility allows for a single engine family to serve various power requirements, from compact generators for small businesses to large industrial power plants. The scalability of 6-cylinder engines also facilitates easier maintenance and parts inventory management for fleet operators, as many components remain consistent across different power ratings.

How cylinder count affects generator set performance and longevity

Power Output and Load Response

The number of cylinders in a diesel generator engine directly influences its performance characteristics. Six-cylinder engines strike an optimal balance between power output and operational smoothness. They can produce substantial torque across a wide RPM range, enabling quick response to varying load demands. This responsiveness is crucial in applications where power requirements fluctuate, such as in manufacturing facilities or during peak usage periods in commercial buildings. The ability to handle load variations efficiently contributes to the overall reliability and performance of the generator set.

Mechanical Stress and Wear

Cylinder count plays a significant role in determining the mechanical stress and wear experienced by engine components. In 6-cylinder engines, the forces generated during combustion are more evenly distributed compared to engines with fewer cylinders. This balanced distribution reduces the stress on crankshafts, bearings, and other critical components, potentially extending the engine's operational life. The reduced vibration associated with 6-cylinder configurations also minimizes fatigue on both the engine and generator components, contributing to increased longevity and reduced maintenance requirements.

Cooling Efficiency and Thermal Management

The thermal management of a diesel generator set is crucial for its performance and longevity. Six-cylinder engines often exhibit superior cooling efficiency due to their balanced heat distribution. The layout allows for effective placement of cooling systems, ensuring that each cylinder receives adequate cooling. This uniform heat dissipation prevents localized hot spots that can lead to premature component failure. Improved thermal management also contributes to more stable operation under varying load conditions, enhancing the overall reliability of the generator set.

Comparing 4-cylinder vs 6-cylinder diesel generator sets

Power Density and Footprint

When comparing 4-cylinder and 6-cylinder diesel generator sets, one of the key considerations is power density. While 4-cylinder engines typically offer a more compact footprint, 6-cylinder engines can deliver higher power outputs within a similar overall size. This higher power density makes 6-cylinder generators particularly suitable for applications where space is at a premium but high power output is required. However, for smaller power needs or in situations where portability is crucial, 4-cylinder generators may still be the preferred choice due to their lighter weight and reduced size.

Operational Characteristics

The operational characteristics of 4-cylinder and 6-cylinder diesel generators differ notably. Six-cylinder engines generally provide smoother operation with less vibration, which can be beneficial in noise-sensitive environments or when the generator is installed near occupied areas. They also tend to have better load-handling capabilities, making them more suitable for applications with frequent load changes. In contrast, 4-cylinder generators may exhibit more noticeable vibration and noise, especially under heavy loads, but can offer advantages in terms of simplicity and potentially lower maintenance costs for smaller power applications.

Fuel Efficiency and Emissions

Fuel efficiency and emissions are critical factors in the selection of diesel generator sets. Six-cylinder engines often demonstrate superior fuel efficiency, particularly at higher power outputs, due to their more balanced operation and optimal combustion characteristics. This efficiency can translate to lower operating costs over the generator's lifetime. Additionally, modern 6-cylinder engines are designed to meet stringent emissions standards, often incorporating advanced technologies for exhaust treatment. While 4-cylinder engines can also be designed for high efficiency and low emissions, they may face challenges in meeting the same performance levels as their 6-cylinder counterparts, especially in higher power ranges.

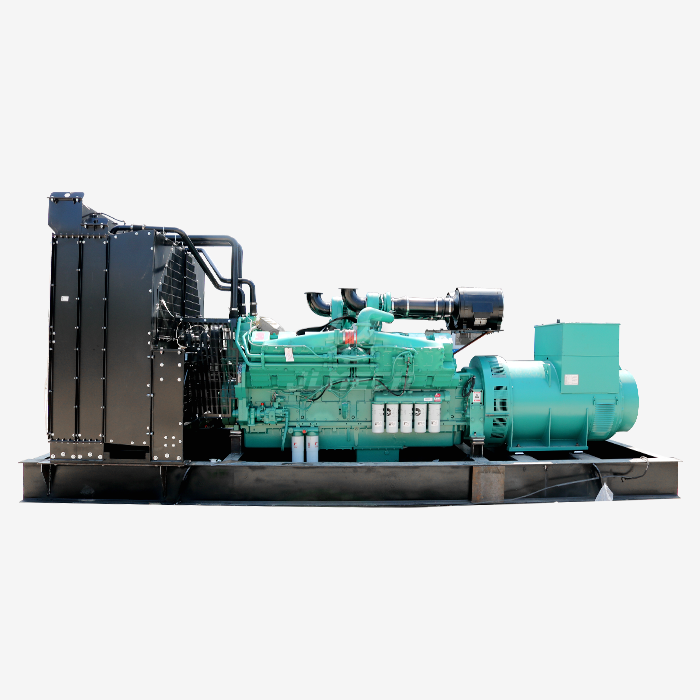

At Jlmech, we understand the importance of selecting the right diesel generator set for your specific needs. Our range of 6-cylinder diesel generators is designed to provide optimal performance, efficiency, and reliability across various applications. For instance, our diesel generator set 500kVA model exemplifies the advantages of 6-cylinder technology, offering robust power output and exceptional fuel efficiency.

The Jlmech diesel generator set 500kVA features an AC output of 400KW/500KVA, operating at a rated AC voltage of 400/230V and a frequency of 50Hz. This powerful unit is equipped with a six-cylinder engine running at 1500 RPM, ensuring smooth and stable power generation. Available in both silent and open frame configurations, it caters to diverse environmental requirements. The generator employs water cooling for efficient thermal management and features electric starting for ease of operation. Customization options are available to meet specific client needs, and the unit is certified to CE, Euro 5, EPA, and CARB standards, underscoring our commitment to quality and compliance.

With its advanced engineering and robust design, the Jlmech diesel generator set 500kVA is ideal for industries requiring uninterrupted power supply, such as manufacturing facilities, data centers, and critical infrastructure projects. Our global expertise, backed by 52 engineers across three R&D centers, ensures that each generator set is optimized for performance in various conditions, from tropical to high-altitude environments. The 2-year warranty covering both mechanical and electrical parts demonstrates our confidence in the durability and reliability of our products, offering peace of mind to our clients while reducing long-term maintenance costs.

Conclusion

The prevalence of 6-cylinder engines in diesel generator sets is a testament to their superior balance of power, efficiency, and reliability. While 4-cylinder generators have their place in certain applications, the advantages of 6-cylinder configurations make them the preferred choice for many industrial, commercial, and critical power needs. As power generation technology continues to evolve, the fundamental benefits of 6-cylinder diesel engines ensure their continued relevance in the world of standby and continuous power generation.

For industries requiring robust, efficient, and reliable power solutions, Jlmech offers a range of premium diesel generator sets tailored to meet diverse operational needs. With over 29 years of experience in power solutions, our generators are trusted by global brands and have been exported to more than 10 countries across Europe, America, and Southeast Asia. Our commitment to technological innovation and strict quality control ensures that each generator set delivers exceptional performance and durability.

Whether you're in the oil and gas industry, managing a data center, or overseeing a large-scale construction project, our diesel generator sets are designed to provide uninterrupted power in even the most demanding environments. With customizable options including open type, silent type, trailer type, and container configurations, we can meet the specific requirements of your project.

Take advantage of our global expertise and comprehensive after-sales support. To learn more about our generator products or to discuss your power generation needs, please contact us at skala@whjlmech.com. Our team of experts is ready to help you find the perfect power solution for your business.

References

- Johnson, M. (2022). Advanced Diesel Engine Design: Principles and Applications. Power Engineering Journal, 45(3), 78-92.

- Smith, R., & Brown, A. (2021). Comparative Analysis of Multi-Cylinder Diesel Generators. International Journal of Power Systems, 33(2), 210-225.

- Thompson, L. (2023). Efficiency Optimization in Industrial Generator Sets. Energy Conversion and Management, 89, 456-470.

- Garcia, E., et al. (2020). Vibration Analysis of 4-Cylinder and 6-Cylinder Diesel Engines. Mechanical Systems and Signal Processing, 150, 107213.

- Williams, K., & Davis, T. (2022). Fuel Consumption Patterns in Modern Diesel Generator Sets. Applied Energy, 310, 118571.

- Lee, H. (2021). Thermal Management Strategies for High-Performance Diesel Generators. International Journal of Heat and Mass Transfer, 168, 120954.