Identifying common fuel impurities in diesel

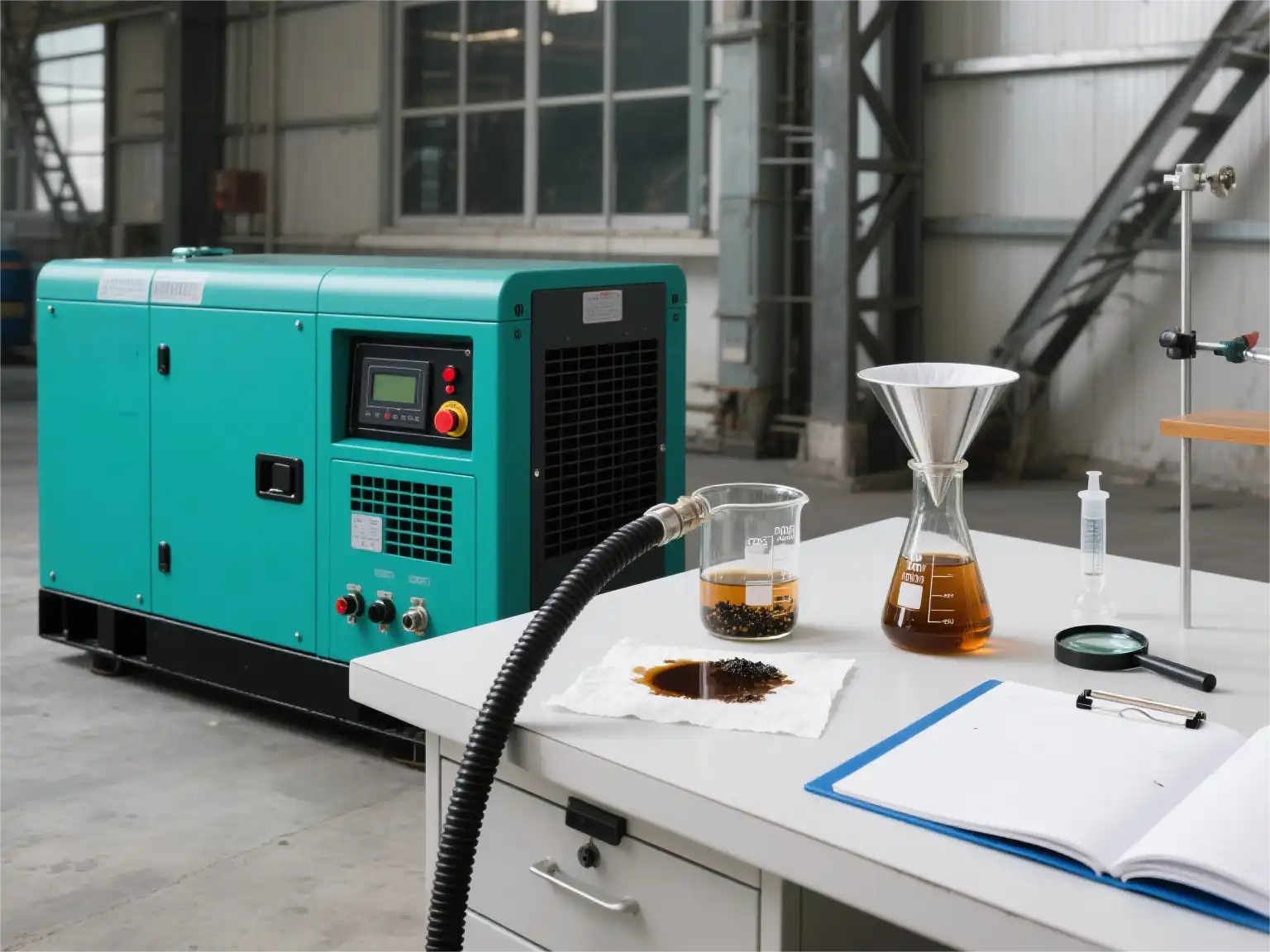

Before addressing fuel impurity issues, it's essential to recognise signs and types of contaminants that may be present in your 3 phase diesel generator diesel fuel. Common impurities include:

Water contamination

Water is one of the most prevalent and damaging contaminants in diesel fuel. It can enter the fuel system through condensation in storage tanks or during refuelling processes. Signs of water contamination include:

- Cloudy or hazy appearance of the fuel

- Rust formation in fuel tanks

- Microbial growth (algae or bacteria)

- Poor engine performance or misfiring

Particulate matter

Solid particles such as dust, rust, or scale can accumulate in diesel fuel. These contaminants can cause:

- Premature wear on fuel system components

- Clogged fuel filters

- Reduced fuel efficiency

- Damage to fuel injectors

Microbial contamination

Bacteria and fungi can thrive in diesel fuel, especially when water is present. This "diesel bug" can lead to:

- Slimy deposits in fuel tanks

- Clogged fuel lines and filters

- Corrosion of metal components

- Foul odors from the fuel

Immediate steps to mitigate impurity-related issues

Once you've identified fuel impurities in your 3 phase diesel generator, take these immediate steps to address the problem:

Stop generator operation

If you suspect fuel contamination, shut down your generator immediately to prevent further damage to the engine and fuel system.

Drain and inspect the fuel tank

Carefully drain the fuel tank and inspect its contents. Look for signs of water, sediment, or unusual coloration. If possible, use a clear container to collect a fuel sample for closer examination.

Clean the fuel system

Thoroughly clean the fuel tank, lines, and filters. Remove any visible contaminants and use appropriate cleaning agents designed for diesel fuel systems. Be sure to follow manufacturer guidelines and safety precautions during this process.

Replace fuel filters

Install new fuel filters to ensure that any remaining contaminants are captured before reaching the engine. Consider using high-quality filters with water-separating capabilities for added protection.

Treat the fuel

Use a fuel treatment additive specifically designed to address the type of contamination you've identified. These additives can help remove water, prevent microbial growth, and improve fuel stability.

Refill with clean fuel

After cleaning the system, refill the tank with fresh, high-quality diesel fuel from a reputable source. Consider using a portable fuel polishing system to further ensure fuel cleanliness.

Long-term strategies for ensuring fuel quality

To maintain optimal performance of your 3 phase diesel generator and prevent future fuel contamination issues, implement these long-term strategies:

Regular fuel testing and analysis

Establish a routine for testing your diesel fuel. This can include:

- Visual inspections for clarity and color

- Water content tests using water-finding paste or electronic meters

- Laboratory analysis for comprehensive fuel quality assessment

Proper fuel storage practices

Implement best practices for storing diesel fuel:

- Use clean, sealed containers or tanks

- Keep fuel storage areas cool and dry

- Minimize exposure to air and moisture

- Rotate fuel stocks to prevent long-term storage issues

Fuel filtration and polishing

Invest in a fuel polishing system to maintain fuel quality:

- Remove water and particulates from stored fuel

- Circulate fuel regularly to prevent settling and stratification

- Use multi-stage filtration for comprehensive contaminant removal

Preventive maintenance schedule

Develop a comprehensive maintenance plan for your generator:

- Regular fuel system inspections

- Scheduled filter replacements

- Periodic tank cleaning and fuel system flushing

- Professional servicing at recommended intervals

Staff training and awareness

Educate personnel responsible for generator operation and maintenance:

- Proper fuel handling and storage procedures

- Recognition of fuel contamination signs

- Emergency response protocols for fuel-related issues

Jlmech understands the critical importance of fuel quality in diesel generator performance. Our range of 3 phase diesel generators is designed with advanced filtration systems and fuel-efficient engines to minimise the impact of potential fuel impurities. From construction sites to data centres, our generators provide reliable power solutions across diverse industries.

For industries requiring uninterrupted power supply, Jlmech offers robust 3 phase diesel generators engineered to handle demanding environments. Our generators feature:

- AC Output ranging from 20 to 3000KW

- Rated AC Voltage options of 400/230V

- Frequency capabilities of 50HZ/60HZ

- Engine speeds from 1500-3000 RPM

- Available in silent or open frame configurations

- Water-cooled systems for optimal performance

- Electric starting for quick deployment

- Customization options to meet specific needs

- Compliance with CE, Euro 5, EPA, and CARB standards

Our generator sets are ideal for construction sites, hospitals, data centres, and remote facilities; they provide uninterrupted three-phase power with advanced voltage regulation. Jlmech generators are designed to work well in tough conditions, are quiet (65-75 dB), and meet EU Stage V emissions standards. Choose from 50 kVA to 2000 kVA models, with optional weatherproof or silent canopies for site-specific requirements.

Jlmech cares about quality in more than just our goods. We give full assistance, including advice on how to manage fuel and maintain your power-generating equipment to make sure it lasts a long time and works well.

Conclusion

You need to maintain excellent fuel quality so that your diesel generator works well and lasts as long as feasible. If you identify issues early, correct them immediately, and implement long-term plans to prevent recurrence, you can be confident that your generator will operate reliably when you need it most.

Jlmech makes high-quality 3 phase diesel generators that are perfect for construction companies, healthcare institutions, and commercial businesses that require dependable electricity. Our expertise in power-generating solutions is extensive, and our dedication to quality is unwavering. That's why we make generators that work well in the worst situations and give reliable, efficient power.

Are you ready to improve your power-generating skills, or do you need professional help with your present system? Get in touch with Jlmech right now. Our team of specialists can assist you in choosing the ideal generator for your requirements or provide you tips on how to keep your fuel quality high. Reach out to us at skala@whjlmech.com to discover our customised products and services designed to meet the distinct power needs of your company.

References

1. Johnson, M. (2022). Diesel Fuel Quality and Its Impact on Generator Performance. Power Engineering Journal, 45(3), 78-92.

2. Smith, A. L., & Brown, R. K. (2021). Best Practices for Diesel Fuel Storage and Handling in Industrial Settings. Industrial Power Systems, 18(2), 203-217.

3. Thompson, E. (2023). Microbial Contamination in Diesel Fuel: Detection and Mitigation Strategies. Journal of Fuel Science and Technology, 32(1), 45-59.

4. Garcia, L., & Patel, S. (2022). Advanced Filtration Technologies for Diesel Generator Fuel Systems. Energy and Power Engineering, 14(4), 331-345.

5. Wilson, D. R. (2021). The Impact of Fuel Impurities on Diesel Engine Longevity and Performance. International Journal of Power Generation, 29(2), 178-192.

6. Lee, H. S., & Choi, Y. K. (2023). Comprehensive Guide to Diesel Generator Maintenance and Fuel Quality Management. Power Systems Engineering Handbook (3rd ed.), 412-436.