What is the process of maintaining a diesel generator?

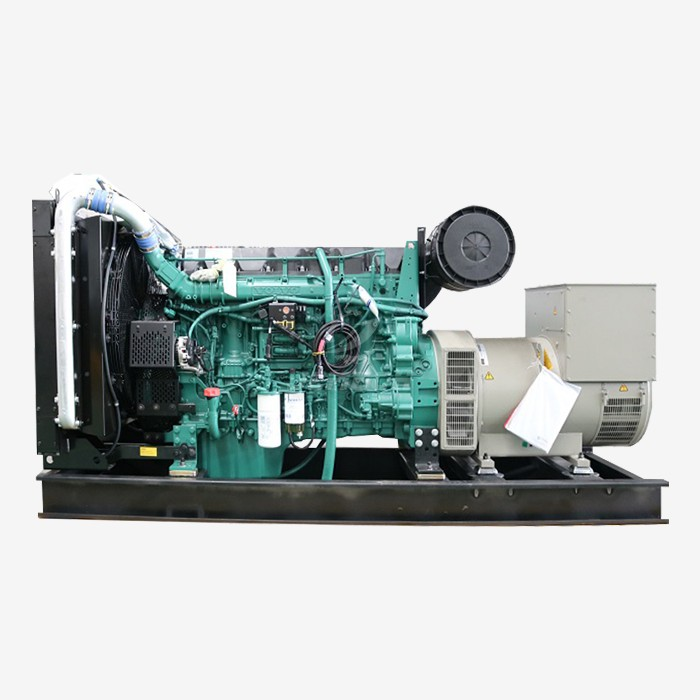

A diesel generator is a significant investment for ensuring business continuity, safety, and operational reliability. However, its value is only realized through a proactive and disciplined maintenance approach. True maintenance goes beyond simply following steps; it requires a mindset of preventive care. Recognizing that a small issue today can prevent a catastrophic failure tomorrow is key. A comprehensive diesel generator maintenance schedule is your primary tool for transforming this awareness into action, safeguarding your power asset against unexpected downtime and costly repairs.

The Maintenance Core

The cornerstone of effective maintenance is adherence to the manufacturer's official diesel generator maintenance schedule. This schedule, found in your operator's manual, is not a suggestion but a meticulously designed plan based on engine runtime hours or elapsed time (whichever comes first). It is engineered to address wear and tear at precise intervals, ensuring optimal performance and longevity. Deviating from this schedule can void warranties and significantly increase the total cost of ownership. Your first and most important step is to locate this document and use it as your maintenance bible.

Maintenance Process Explained

A typical maintenance regimen is structured around increasing intervals of complexity and thoroughness.

Daily/Weekly Checks (Operator Visual Inspections):

Check fuel, coolant, and engine oil levels.

Inspect the unit for any signs of fluid leaks (oil, coolant, fuel).

Ensure the area around the generator is clean and free of debris.

Note any fault codes on the control panel.

Monthly/Quarterly Tasks:

Run the generator under load for at least 30 minutes. This exercises the engine, burns off moisture, and verifies system operation.

Check battery terminals for corrosion and ensure they are tight and clean.

Inspect drive belts for cracks and proper tension.

Check the air filter restriction indicator.

Annual Service (Requires a Certified Technician):

This is the most critical service interval and should be performed by a qualified professional. It generally includes:

Changing the engine oil and oil filter.

Replacing the fuel filter(s).

Replacing the air filter.

Draining and replacing the coolant, checking the concentration of antifreeze/corrosion inhibitor.

Testing and inspecting the automatic transfer switch (ATS).

A comprehensive inspection of all hoses, connections, and wiring.

Adhering to this structured diesel generator maintenance schedule is non-negotiable for reliability.

Seasonal Maintenance

Environmental changes demand additional vigilance. A thorough diesel generator maintenance schedule accounts for seasonal variations.

Summer/Warm Weather: Focus on cooling system efficiency. Ensure the radiator fins are clean and free of debris. Verify coolant concentration to prevent overheating. Check that cooling fans are operating correctly.

Winter/Cold Weather: Prioritize startability. Use winter-grade fuel to prevent waxing. Test block heaters and ensure glow plugs or intake grid heaters are functional. Check the battery's cold cranking amps (CCA) as cold weather reduces its output. This proactive, seasonal adjustment is a hallmark of a mature maintenance strategy.

Maintenance Records

Meticulous record-keeping is often the most overlooked aspect of maintenance. A detailed log of all services, inspections, and repairs is not just a diary; it is a valuable asset. It provides:

Proof of Compliance: Essential for meeting insurance and regulatory requirements.

Increased Resale Value: Demonstrates to potential buyers that the asset has been cared for professionally.

Historical Data: Allows technicians to quickly diagnose recurring issues based on past trends.

Warranty Validation: Provides necessary proof that maintenance was performed to the manufacturer's standards. A complete diesel generator maintenance schedule includes a system for flawless record-keeping.

Conclusion

A disciplined maintenance process is the definitive factor that separates a reliable power source from an unreliable liability. It is a systematic investment that pays dividends in extended engine life, unwavering reliability, and lower total operating costs. By understanding, implementing, and documenting a rigorous diesel generator maintenance schedule, you protect your operations and your capital investment.

JLMECH possesses extensive expertise in power generation solutions and upholds an unwavering commitment to quality. We don't just build durable generators; we provide the support to keep them running for years to come.

Ensure your generator is always mission-ready. Our expert team at JLMECH is here to help. We offer comprehensive service contracts, genuine maintenance kits, and technical support. Email us at skala@whjlmech.com to learn about our custom products and services designed to meet your unique power requirements.

References

International Organization for Standardization. (2018). *ISO 8528-5:2018 Reciprocating internal combustion engine driven alternating current generating sets — Part 5: Generating sets*. Geneva, Switzerland.

National Fire Protection Association. (2022). NFPA 110: Standard for Emergency and Standby Power Systems. Quincy, MA, USA.

Davis, T. (2021). Proactive Maintenance Strategies for Critical Power Assets. Facility Management Journal, 28(1), 34-48.