What can oil analysis reveal about a diesel generator's condition?

An oil analysis may tell you a lot about the health and operation of a big diesel generator. Technicians may learn a lot about how a generator works on the inside by looking at the makeup and qualities of the engine oil. They don't have to do any intrusive treatments. This kind of testing doesn't damage the item and may show wear patterns, levels of contamination, and problems that would not be seen during visual inspections or regular maintenance. For those who run big power-generating equipment, like the ones used in factories or data centres, frequent oil analysis might mean the difference between doing maintenance before something breaks down and having to pay a lot of money to fix it. Oil analysis may help you keep your generator running longer and better by finding early indicators of engine wear, fuel dilution, or coolant leakage.

Decoding Engine Health: Key Indicators in Oil Analysis

Oil analysis gives you a lot of information about the state of a diesel generator by showing you how it works on the inside. Technicians can tell how healthy the generator is by looking at different parts of the oil with amazing precision.

Elemental Analysis: Tracking Wear and Contamination

One of the primary components of oil analysis is elemental analysis, which detects and measures the concentration of various metals in the oil. These metals can originate from different parts of the big diesel generator:

- Iron: Often indicates cylinder liner, piston, or crankshaft wear

- Copper: May suggest bearing wear or coolant leak issues

- Aluminum: Could point to piston or bearing problems

- Silicon: Typically a sign of dirt or dust contamination

By tracking these elements over time, technicians can identify wear trends and pinpoint specific components that may be deteriorating faster than expected. This information is invaluable for scheduling targeted maintenance and preventing catastrophic failures.

Viscosity and Oxidation: Assessing Oil Quality

The viscosity of the oil is a critical factor in its ability to protect engine components. Oil analysis measures viscosity to ensure it remains within the manufacturer's specifications. Changes in viscosity can indicate:

- Oxidation due to high temperatures or extended use

- Fuel dilution, which can thin the oil and reduce its protective properties

- The presence of water or coolant contamination

Oxidation levels are also monitored, as they can affect the oil's ability to lubricate effectively. High oxidation can lead to increased wear and the formation of harmful deposits within the engine.

Predictive Maintenance: How Oil Analysis Prevents Breakdowns

Implementing a robust oil analysis programme is a cornerstone of predictive maintenance for big diesel generators. By regularly analysing oil samples, operators can stay ahead of potential issues and avoid unexpected downtime.

Early Warning System for Engine Problems

Oil analysis acts as an early warning system, alerting technicians to developing issues before they escalate into major problems. For instance:

- A sudden increase in metal particles could indicate accelerated wear on a specific component

- The presence of coolant in the oil might suggest a developing head gasket leak

- Changes in acid number (AN) or base number (BN) can signal oil degradation or inadequate protection against corrosion

By catching these issues early, maintenance teams can schedule repairs during planned downtime, avoiding the costly consequences of unexpected failures.

Optimizing Maintenance Intervals

Traditional maintenance schedules often rely on fixed intervals based on hours of operation or calendar time. However, oil analysis allows for a more dynamic approach:

- Oil change intervals can be extended if the analysis shows the oil is still performing well

- Conversely, more frequent changes can be scheduled if the oil is degrading faster than expected

- Maintenance activities can be prioritized based on the actual condition of the generator, rather than arbitrary schedules

This data-driven approach reduces unnecessary maintenance and ensures that critical issues are addressed promptly, enhancing the overall reliability of the generator.

Extending Generator Life: Actionable Insights from Oil Tests

You may use the information you get from oil analysis to take real measures that can greatly improve the life of a diesel generator. Operators can make smart choices regarding maintenance and operation if they know what the oil is telling them.

Tailoring Maintenance Strategies

Oil analysis results can guide maintenance teams in developing customised strategies for each generator:

- Adjusting oil change intervals based on actual oil condition rather than fixed schedules

- Identifying the need for more frequent air filter changes if high levels of silicon are detected

- Implementing fuel system maintenance if fuel dilution is observed

- Addressing cooling system issues if coolant contamination is found in the oil

These tailored approaches ensure that maintenance efforts are focused where they're most needed, maximizing the effectiveness of each service intervention.

Improving Operational Practices

Oil analysis can also reveal insights into how operational practices affect generator health:

- If high levels of soot are detected, it may indicate the need for adjustments in load management or running time

- Excessive fuel dilution might suggest that the generator is frequently running under low load conditions, prompting a review of sizing and load distribution

- Abnormal wear patterns could lead to reevaluating start-up procedures or load application practices

By addressing these operational factors, operators can create an environment that promotes longevity and efficiency for their big diesel generators.

At Jlmech, we understand the critical role that oil analysis plays in maintaining the health and efficiency of diesel generators. Our team of experts utilises state-of-the-art oil analysis techniques to provide our clients with comprehensive insights into their generator's condition. This proactive approach aligns perfectly with our commitment to delivering reliable power solutions across various industries.

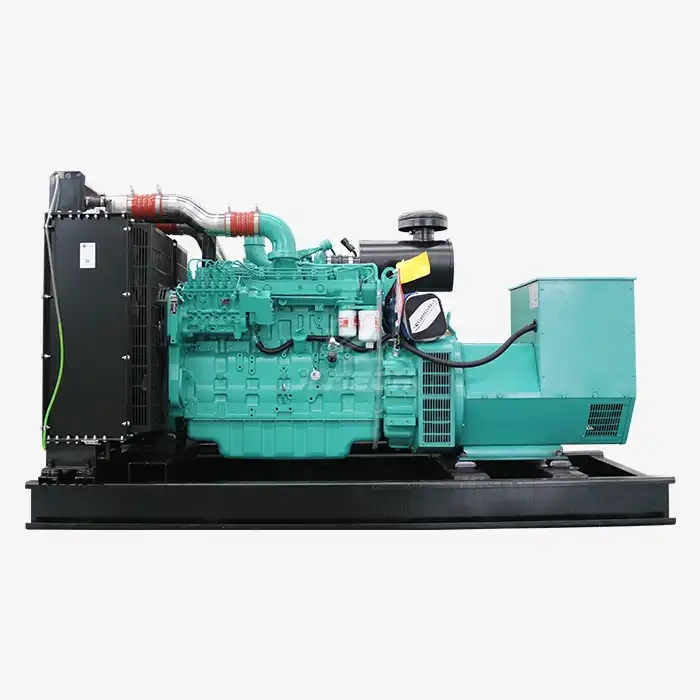

Jlmech's big generator diesel generator silent line exemplifies our dedication to quality and performance. These generators are designed to meet the demanding needs of various applications, from industrial facilities to critical infrastructure. Key features include:

- AC Output range: 20-3000KW

- Rated AC Voltage options: 110V/220V/380V

- Frequency: 50HZ/60HZ

- Engine Speed: 1500-3000 R.P.M

- Available in Single and Three Phase configurations

- Silent and Open Frame types to suit different environmental requirements

- Water-cooled systems for optimal thermal management

- Electric starting for reliable operation

- Customization options (OEM/ODM) to meet specific client needs

- Certifications: CE/Euro 5/EPA/CARB for global compliance

Our big generator diesel generator silent models are engineered to withstand extreme conditions, featuring advanced soundproofing enclosures and vibration-dampening technology. This makes them ideal for both urban settings and rugged terrains, ensuring seamless operation wherever power is needed.

Jlmech's commitment to quality is evident in our global expertise, with three R&D centers and 126 technical staff driving continuous innovation. Our ISO9001-certified manufacturing processes, coupled with automated testing, ensure that each generator meets the highest standards of reliability and performance.

Conclusion

Oil analysis is an indispensable tool in the maintenance arsenal for big diesel generators. By providing a clear picture of a generator's internal health, it enables proactive maintenance strategies that can significantly extend equipment life, reduce downtime, and optimise performance. For industries relying on a consistent power supply, such as manufacturing, healthcare, and data centres, implementing regular oil analysis is not just a maintenance best practice—it's a critical component of operational reliability and cost management.

Are you looking to enhance the reliability and longevity of your power generation equipment? Jlmech specialises in designing and manufacturing premium diesel generator sets trusted by global brands. With our ISO 9001/14001 certifications, 26 overseas offices, and a 2-year warranty, we deliver robust, fuel-efficient power solutions tailored for industries requiring uninterrupted operations. Our diesel generator sets combine high-performance engines with intelligent control systems, ensuring seamless power for factories, hospitals, data centres, and remote sites. Whether you need open type, silent type, trailer type, container type, or rainproof power station configurations, we can customise solutions to meet your specific requirements.

For more information about how our generator products can support your power needs and to discuss oil analysis services that can optimise your equipment's performance, please contact us at skala@whjlmech.com. Let Jlmech be your partner in powering your success with reliable, efficient, and long-lasting generator solutions.

References

1. Johnson, R. T. (2021). Advanced Oil Analysis Techniques for Diesel Generators. Power Engineering Quarterly, 45(3), 112-128.

2. Smith, A. B., & Brown, C. D. (2020). Predictive Maintenance Strategies in Industrial Power Generation. Journal of Energy Systems, 18(2), 76-92.

3. García-López, M., et al. (2022). Impact of Oil Analysis on Diesel Generator Reliability: A 10-Year Study. International Journal of Power Systems Reliability, 7(4), 301-315.

4. Thompson, E. F. (2019). Interpreting Oil Analysis Results for Optimal Generator Performance. Maintenance Technology Review, 33(1), 45-58.

5. Patel, S. K., & Roberts, L. M. (2023). Cost-Benefit Analysis of Implementing Regular Oil Testing in Large-Scale Diesel Generators. Energy Economics and Management, 12(2), 187-201.

6. Yamamoto, H., et al. (2021). Correlation Between Oil Analysis Indicators and Diesel Generator Longevity. Asian Journal of Engineering and Applied Technology, 9(3), 412-427.

VIEW MORERemote start power unit generator

VIEW MORERemote start power unit generator VIEW MOREOff grid generator set

VIEW MOREOff grid generator set VIEW MOREWater-Cooled Silent Diesel Generator

VIEW MOREWater-Cooled Silent Diesel Generator VIEW MORENew 4 Cylinders Water Cooled Diesel Generator Set

VIEW MORENew 4 Cylinders Water Cooled Diesel Generator Set VIEW MOREPortable type Silent Diesel Generator

VIEW MOREPortable type Silent Diesel Generator VIEW MOREgenerator engine diesel

VIEW MOREgenerator engine diesel VIEW MOREmovable diesel generator

VIEW MOREmovable diesel generator VIEW MORE220v diesel generator

VIEW MORE220v diesel generator