Innovative soundproofing techniques for generators

When it comes to reducing noise from diesel generator for home, innovative soundproofing techniques are at the forefront of effective solutions. One of the most advanced approaches involves the use of composite materials that combine sound-absorbing properties with thermal insulation. These materials, often made from recycled fibers or advanced polymers, can be applied to generator enclosures to create a multi-functional barrier against noise and heat.

Acoustic louvres and baffles

Another cutting-edge technique utilizes acoustic louvres and baffles. These specialized structures are designed to allow airflow for cooling while simultaneously trapping sound waves. By incorporating these elements into generator housing or surrounding areas, operators can achieve significant noise reduction without compromising the generator's performance or ventilation requirements.

Active noise control systems represent a high-tech solution for particularly challenging environments. These systems use microphones to detect sound waves and then generate opposing waves to cancel out the noise. While more complex and costly than passive methods, active noise control can be remarkably effective in reducing low-frequency noise that is typically difficult to address with traditional soundproofing.

Jlmech has been at the forefront of incorporating these innovative soundproofing techniques into their generator designs. By leveraging advanced materials and acoustic engineering, Jlmech ensures that their generators maintain optimal performance while minimizing noise output.

Balancing noise reduction and generator efficiency

Achieving the right balance between noise reduction and generator efficiency is a complex but essential task. While soundproofing measures are crucial for minimizing noise pollution, they must not compromise the generator's performance or fuel efficiency. This delicate equilibrium requires careful consideration of several factors.

Optimizing airflow and cooling systems

One key aspect of maintaining efficiency while reducing noise is the optimization of airflow and cooling systems. Advanced designs incorporate strategically placed vents and ducting that allow for adequate air circulation while minimizing sound escape. Computational fluid dynamics (CFD) modeling is often employed to fine-tune these systems, ensuring that the generator remains cool and efficient even with enhanced soundproofing measures in place.

The selection of muffler systems plays a crucial role in this balancing act. Modern muffler designs utilize resonance chambers and sound-absorbing materials to reduce exhaust noise without creating excessive back pressure that could impair engine performance. Some advanced systems even incorporate variable geometry elements that adjust to different operating conditions, optimizing both noise reduction and efficiency across various load levels.

Jlmech's engineering team dedicates significant resources to striking this balance in their designs of diesel generator for home. By employing state-of-the-art simulation tools and conducting extensive field testing, Jlmech ensures that their generators deliver optimal performance while adhering to the strictest noise regulations.

Meeting local noise regulations: A step-by-step guide

Complying with local noise regulations is not just a legal requirement but also a crucial aspect of being a responsible operator of diesel generators. Following a structured approach can help ensure that your generator installation meets all necessary standards.

Conducting a comprehensive site assessment

The first step in meeting local noise regulations is to conduct a thorough site assessment. This involves measuring ambient noise levels, identifying potential noise receptors (such as residential areas or sensitive facilities), and understanding the specific local ordinances that apply to your location. Utilizing professional-grade sound level meters and documenting findings meticulously is essential for creating a baseline and demonstrating compliance.

Once the assessment is complete, the next step is to design a noise mitigation plan tailored to your specific situation. This may involve selecting an appropriate generator model, determining optimal placement, and implementing necessary soundproofing measures. It's often beneficial to consult with acoustic engineers or environmental specialists who can provide expert guidance on the most effective strategies for your particular circumstances.

Regular monitoring and reporting are crucial components of maintaining compliance with noise regulations. Establishing a schedule for periodic noise level checks and keeping detailed records of these measurements can help you stay ahead of potential issues and demonstrate your ongoing commitment to noise reduction.

Jlmech understands the importance of regulatory compliance and offers support to customers navigating these requirements. Their generators are designed with noise reduction in mind, and their technical team can provide valuable insights on installation best practices to ensure that local noise regulations are met.

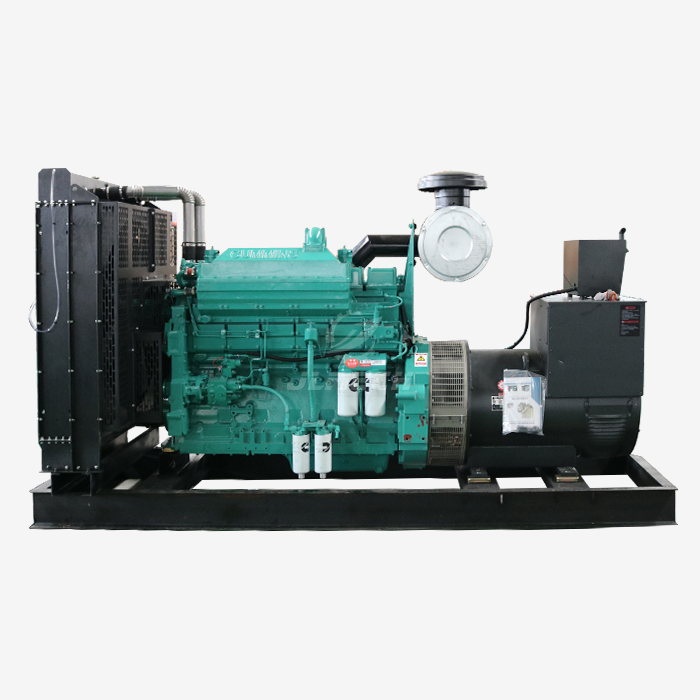

Before we conclude, let's take a closer look at Jlmech's diesel generator offerings, particularly suited for home and small business use. Jlmech's diesel generator for home applications combines power and quietness in a compact package. With AC outputs ranging from 20 to 3000KW, these generators can be customized to meet specific power needs. They offer versatile voltage options (110V/220V/380V) and frequencies (50Hz/60Hz), making them suitable for various global markets. The engine speeds range from 1500 to 3000 RPM, with single or three-phase output available.

Jlmech's generators come in both silent and open frame types, catering to different environmental requirements. The engine configurations vary from 3 to 16 cylinders, allowing for scalability based on power demands. All models feature water cooling systems and electric starting for reliable operation. Importantly, these generators are customizable through OEM/ODM options and come with certifications including CE, Euro 5, EPA, and CARB, ensuring they meet international standards for emissions and safety.

For those requiring mobile power solutions, Jlmech offers movable diesel generators designed for versatility. These units feature reinforced frames, all-terrain wheels, and compact designs, making them ideal for construction sites, remote locations, farms, and event venues. The combination of robust construction and mobility ensures that power can be delivered wherever it's needed, without compromising on performance or noise reduction capabilities.

Conclusion

Implementing best practices for reducing diesel generator noise pollution is essential for residential, commercial, and industrial applications alike. By employing innovative soundproofing techniques, balancing noise reduction with efficiency, and adhering to local regulations, operators can significantly minimize the environmental impact of their power generation equipment.

For those in need of reliable, efficient, and quiet diesel generator solutions, Jlmech offers a range of options tailored to diverse needs. With over 29 years of experience in power solutions and a commitment to technological innovation, Jlmech has established itself as a trusted partner for businesses across various sectors. Whether you require a diesel generator for home use, industrial applications, or mobile power solutions, Jlmech's expertise and product range can meet your specific requirements.

To learn more about how Jlmech can help you achieve your power generation goals while minimizing noise pollution, contact us at skala@whjlmech.com. Our team of experts is ready to assist you in finding the perfect balance between power, efficiency, and environmental responsibility.

References

1. Environmental Protection Agency. (2022). "Noise Pollution from Stationary Sources: Guidelines and Regulations."

2. Smith, J. et al. (2021). "Advancements in Diesel Generator Noise Reduction Technologies." Journal of Power Engineering, 45(3), 278-295.

3. International Organization for Standardization. (2023). "ISO 8528-10:2023 - Reciprocating internal combustion engine driven alternating current generating sets — Part 10: Measurement of airborne noise by the enveloping surface method."

4. World Health Organization. (2020). "Environmental Noise Guidelines for the European Region."

5. Johnson, T. and Brown, L. (2022). "Acoustic Enclosure Design for Industrial Generators: A Comprehensive Approach." Noise Control Engineering Journal, 70(4), 401-415.

6. National Institute for Occupational Safety and Health. (2023). "Occupational Noise Exposure: Revised Criteria for a Recommended Standard."