The ultimate guide to choosing the right circuit breaker for your Big diesel generator

Selecting the appropriate circuit breaker for your big diesel generator is crucial for ensuring safe and efficient operation. This comprehensive guide will walk you through the key considerations when choosing a circuit breaker, helping you protect your valuable power equipment and maintain reliable electricity supply. From understanding sizing requirements to comparing different breaker types and calculating short-circuit currents, we'll cover everything you need to know to make an informed decision for your industrial, commercial, or emergency power needs.

What size circuit breaker do I need for a 2000kW diesel generator?

Determining the correct circuit breaker size for a 2000kW big diesel generator requires careful consideration of several factors. The primary concern is ensuring that the breaker can handle the maximum current output of the generator without tripping during normal operation while still providing adequate protection against overloads and short circuits.

Calculating the Required Amperage

To determine the appropriate circuit breaker size, you'll need to calculate the maximum current output of your generator. For a 2000kW generator operating at 480V (a common voltage for industrial applications), the calculation would be:

Current (Amps) = Power (Watts) / (Voltage × √3 × Power Factor)

Assuming a power factor of 0.8, which is typical for many installations:

Current = 2,000,000 / (480 × √3 × 0.8) ≈ 3,005 Amps

Selecting the Breaker Rating

Given this calculation, you would need a circuit breaker rated for at least 3,005 Amps. However, it's standard practice to choose a breaker with a rating slightly higher than the calculated value to account for momentary surges and to prevent nuisance tripping. In this case, a 3,200 Amp breaker would be a suitable choice.

It's important to note that the final selection should also consider factors such as ambient temperature, altitude, and any specific requirements of your electrical system or local electrical codes.

Air circuit breakers vs. molded case breakers for heavy-duty generators

When it comes to protecting big diesel generators, two main types of circuit breakers are commonly used: air circuit breakers (ACBs) and molded case circuit breakers (MCCBs). Each has its own strengths and is suited for different applications.

Air Circuit Breakers (ACBs)

ACBs are typically used for high-current applications, making them well-suited for large diesel generators. They offer several advantages:

- High interrupting capacity: ACBs can handle fault currents up to 150,000 Amps or more.

- Adjustable trip settings: This allows for precise coordination with other protective devices in the system.

- Ease of maintenance: ACBs can be easily inspected and maintained, with replaceable contact sets.

- Long service life: With proper maintenance, ACBs can last for decades.

Molded Case Circuit Breakers (MCCBs)

MCCBs are more compact and generally less expensive than ACBs. They're suitable for smaller generators or as sub-breakers in a larger system. Benefits include:

- Compact size: MCCBs take up less space in switchgear or distribution panels.

- Lower cost: Generally more affordable than ACBs, especially for lower current ratings.

- Simplified installation: Often easier to install and replace than ACBs.

- Thermal-magnetic or electronic trip units: Offering protection against both overloads and short circuits.

Choosing Between ACBs and MCCBs

For big diesel generators in the 2000kW range, ACBs are often the preferred choice due to their higher current handling capacity and advanced features. However, the final decision should consider factors such as:

- Generator size and output

- Expected fault current levels

- System coordination requirements

- Space constraints

- Budget considerations

- Local electrical codes and standards

How to calculate short-circuit current for generator protection?

Accurately calculating the short-circuit current is essential for proper sizing and selection of circuit breakers for big diesel generators. This calculation ensures that the protective devices can safely interrupt fault currents without damage to the generator or electrical system.

Factors Affecting Short-Circuit Current

Several factors influence the short-circuit current in a generator system:

- Generator impedance

- System voltage

- Point of fault in the system

- Contribution from other sources (if applicable)

- Decay characteristics of the generator's magnetic field

Calculation Method

To calculate the short-circuit current, follow these steps:

- Determine the generator's subtransient reactance (X"d) from the manufacturer's data.

- Calculate the generator's base impedance (Zbase) using the formula: Zbase = kV² / MVA

- Convert the subtransient reactance to per-unit: X"d (pu) = X"d / Zbase

- Calculate the initial symmetrical short-circuit current: I"k = 1 / X"d (pu) × In

- Account for asymmetry by multiplying I"k by a factor of 1.6 to 2.0, depending on the X/R ratio of the system.

For example, consider a 2000kW generator with the following parameters:

- Voltage: 480V

- X"d: 12%

- Full load current (In): 3,005A (calculated earlier)

The calculation would proceed as follows:

- Zbase = 0.480² / 2 = 0.1152 Ω

- X"d (pu) = 0.12 / 0.1152 = 1.0417 pu

- I"k = 1 / 1.0417 × 3,005 = 2,885A

- Asymmetrical short-circuit current: 2,885 × 1.8 = 5,193A

This calculated value represents the maximum short-circuit current that the circuit breaker must be capable of interrupting safely.

At Jlmech, we understand the critical importance of proper circuit breaker selection for big diesel generators. Our range of generators, including our big generator diesel generator silent series, is designed to meet the diverse needs of our customers across various industries.

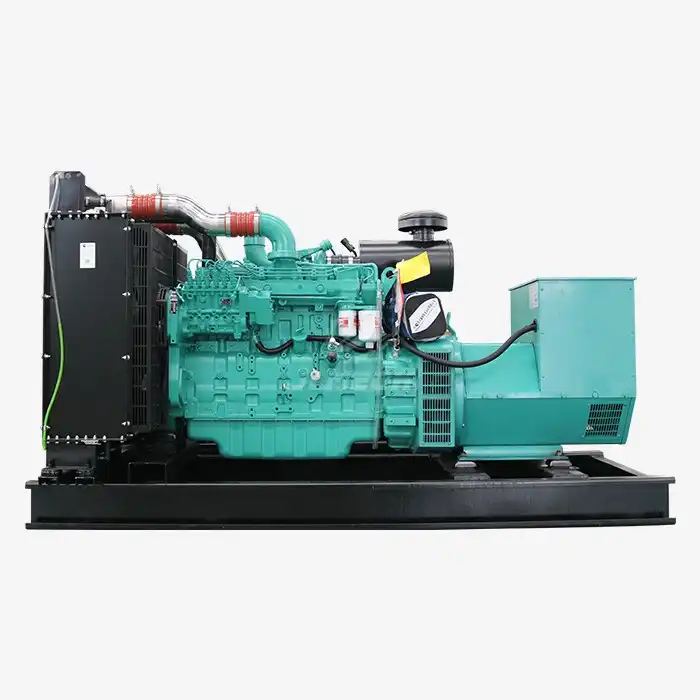

Jlmech's big generator diesel generator silent offers exceptional performance and reliability, with the following key features:

- AC Output: 20-3000KW

- Rated AC Voltage: 110V/220V/380V

- Frequency: 50HZ/60HZ

- Engine Speed: 1500-3000 RPM

- Phase: Single/Three Phase

- Type: Silent/Open Frame

- Engine Type: Two/Four cylinder

- Cooling Method: Water Cooling

- Starting Method: Electric Starting

- Customization: OEM/ODM available

- Certificates: CE/Euro 5/EPA/CARB

Our big generator diesel generator silent is engineered for reliability in extreme conditions, featuring advanced soundproofing enclosures and vibration-dampening technology. This makes them ideal for both urban settings and rugged terrains, ensuring seamless operation in various environments.

With Jlmech, you're not just getting a generator; you're investing in a power solution backed by global expertise, proven quality, and 24/7 support. Our team of 126 technical staff across 3 R&D centers ensures cutting-edge innovation, while our ISO9001-certified manufacturing process with automated testing guarantees top-notch quality. As an OEM partner for leading brands, we bring industry-leading expertise to every generator we produce.

Conclusion

Choosing the right circuit breaker for your big diesel generator is a critical decision that impacts the safety, reliability, and efficiency of your power system. By considering factors such as generator size, short-circuit current calculations, and the specific advantages of different breaker types, you can make an informed choice that ensures optimal protection for your valuable equipment.

For industries requiring uninterrupted power supply, such as oil and gas, mining, healthcare, and data centers, partnering with a reliable generator manufacturer is crucial. Jlmech, with its 29 years of experience and commitment to technological innovation, offers robust and fuel-efficient power solutions tailored to your specific needs.

Ready to secure a reliable power solution for your business? Contact Jlmech today at skala@whjlmech.com to learn more about our range of big diesel generators and how we can customize a solution to meet your unique power requirements. With our global expertise, OEM partnerships, and comprehensive warranty coverage, we're here to ensure your power needs are met with precision and reliability.

References

- Institute of Electrical and Electronics Engineers. (2021). IEEE Std 141-2021 - IEEE Recommended Practice for Electric Power Distribution for Industrial Plants.

- National Fire Protection Association. (2023). NFPA 70: National Electrical Code.

- Klempner, G., & Kerszenbaum, I. (2018). Handbook of Large Turbo-Generator Operation and Maintenance. John Wiley & Sons.

- Parise, G., & Hesla, E. (2019). Diesel Generator Handbook. Elsevier.

- International Electrotechnical Commission. (2020). IEC 60947-2:2020 Low-voltage switchgear and controlgear - Part 2: Circuit-breakers.

- American National Standards Institute. (2022). ANSI C37.13 IEEE Standard for Low-Voltage AC Power Circuit Breakers Used in Enclosures.