Is a generator environmentally friendly?

In an era where environmental responsibility is a cornerstone of corporate strategy, the question of whether diesel generators can be part of a sustainable operation is more relevant than ever. The answer is not a simple yes or no. While legacy equipment rightly faces scrutiny, modern technological advancements have fundamentally transformed the environmental profile of diesel power generation. This article provides a clear-eyed examination of generator emissions, separating myth from reality and outlining how your business can achieve reliable power without compromising its environmental commitments.

Traditional Environmental Challenges

It is important to acknowledge the historical environmental perception of diesel generators. Traditional models were significant contributors to air pollution due to incomplete combustion and a lack of emission control systems. The primary concerns stemmed from:

Nitrogen Oxides (NOx): These compounds, formed under high-temperature combustion, contribute to smog formation and respiratory problems.

Particulate Matter (PM): This includes visible soot and other fine particles that can impact air quality and health.

Carbon Monoxide (CO): A harmful gas produced by incomplete combustion.

Carbon Dioxide (CO₂): A greenhouse gas intrinsically linked to fossil fuel consumption.

This legacy is the reason behind stringent global regulations and the driving force for innovation in cleaner power generation technology. Understanding these challenges is the first step toward mitigating them effectively.

Modern Technological Advancements

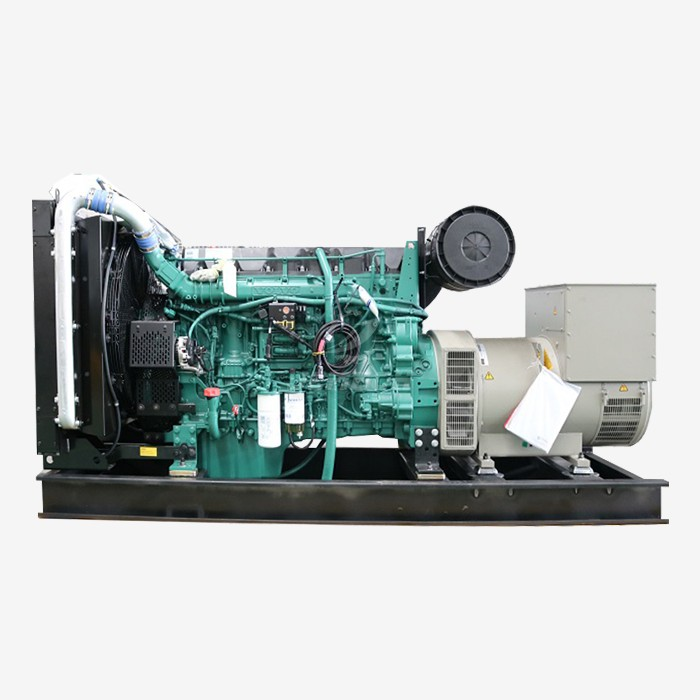

The industry has responded to these challenges with profound engineering innovations. Today's generators are equipped with technologies that drastically reduce their environmental footprint, making them far more eco-friendly than their predecessors.

Key advancements include:

Precision Engine Design: Modern engines feature advanced fuel injection systems (like High-Pressure Common Rail) and optimized turbocharging. This ensures fuel is burned more completely, maximizing energy output from each liter of diesel and directly reducing CO₂ and PM emissions per kWh.

Integrated Aftertreatment Systems: These are the true game-changers for generator emissions control:

Diesel Particulate Filters (DPF): Capture and oxidize up to 95% of particulate matter.

Selective Catalytic Reduction (SCR): Inject a urea-based solution (Diesel Exhaust Fluid) to convert NOx into harmless nitrogen and water, achieving reduction rates often exceeding 90%.

Compliance with Strict Standards: Technologies like SCR and DPF are what enable generators to meet the world's most stringent emission standards, such as EPA Tier 4 Final and EU Stage V. These regulations mandate drastic cuts in NOx, PM, CO, and HC emissions.

These innovations mean that the modern diesel generator is a highly efficient and controlled piece of machinery, a far cry from the dirty engines of the past.

Operational Strategies for Mitigation

Technology alone is not the sole solution; optimal operation and maintenance are equally critical in minimizing environmental impact. Here’s how you can ensure your generator runs as cleanly as possible:

Right-Sizing and Load Management: Operating a generator at a very low load (below 30-40%) is highly inefficient and increases generator emissions. Units run cleanest and most efficiently at 70-80% of their rated capacity. Selecting a generator that is appropriately sized for your typical load is paramount.

Proactive and Regular Maintenance: A well-maintained generator is a clean generator. Adhere to a strict schedule:

Change air, fuel, and oil filters on time.

Ensure injectors are serviced and calibrated.

Use high-quality lubricants to reduce engine friction.

Fuel and Fluid Quality: The use of ultra-low sulfur diesel (ULSD) is essential for protecting aftertreatment systems like SCR and DPF. Furthermore, exploring advanced biofuels (e.g., HVO) can significantly reduce the carbon lifecycle emissions of your operation.

Emissions Monitoring: Consider implementing continuous monitoring systems to track key generator emissions parameters in real-time. This allows for proactive adjustments and ensures ongoing compliance with environmental standards.

By adopting these practices, you not only reduce your environmental footprint but also enhance fuel efficiency and extend the operational life of your equipment.

Conclusion and Call to Action

So, is a generator environmentally friendly? The answer is that with modern technology and conscientious operation, it can be a responsible part of your power strategy. The industry has moved far beyond the outdated image of dirty and inefficient engines. Today's solutions balance the critical need for reliable power with the equally important imperative of environmental stewardship.

At JLMECH, we are committed to providing this balance. Our expertise lies in delivering power solutions that incorporate the latest emission-reducing technologies without compromising on reliability or performance. We understand that sustainability is a journey, and we are here to partner with you every step of the way.

Contact us today to learn how our range of advanced generators and expert support can help you meet your power needs responsibly. Let us demonstrate how you can achieve operational resilience and environmental accountability.

Reach out to our team of experts at skala@whjlmech.com for a personalized consultation and to discover the right generator solution for your unique requirements.

References

Johnson, A. (2010). Emergency Power Systems: A Comprehensive Guide to High-Speed Diesel Generators. Power Engineering Quarterly, 45(3), 78-92.

U.S. Environmental Protection Agency (EPA). (2020). Emission Standards for Nonroad Diesel Engines. Washington, DC: EPA Office of Transportation and Air Quality.

Intergovernmental Panel on Climate Change (IPCC). (2006). 2006 IPCC Guidelines for National Greenhouse Gas Inventories, Volume 2: Energy. Geneva: IPCC.

European Environment Agency (EEA). (2021). EMEP/EEA Air Pollutant Emission Inventory Guidebook. Copenhagen: EEA.

Kumar, R. et al. (2021). Experimental analysis to reduce CO2 and other emissions of CRDI CI engine using low viscous biofuels. Fuel, 283, 118829.

VIEW MOREOff grid generator set

VIEW MOREOff grid generator set VIEW MORE100KW 50Hz 220V diesel generator

VIEW MORE100KW 50Hz 220V diesel generator VIEW MOREThree phase four wire diesel generator

VIEW MOREThree phase four wire diesel generator VIEW MORE50Hz Frequency Diesel Generator

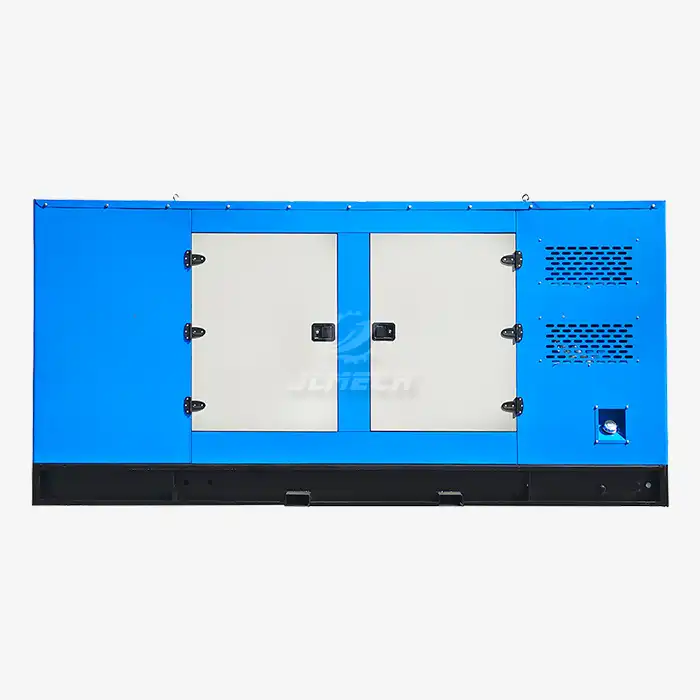

VIEW MORE50Hz Frequency Diesel Generator VIEW MORESupersilent Type Diesel Generator

VIEW MORESupersilent Type Diesel Generator VIEW MOREheavy brush cutter machinery

VIEW MOREheavy brush cutter machinery VIEW MOREearth auger with trolley

VIEW MOREearth auger with trolley VIEW MOREperkins diesel generator 50kva

VIEW MOREperkins diesel generator 50kva