Diesel fuel can be prone to issues that affect startup performance. In colder environments, diesel fuel may gel or develop wax crystals, impeding proper flow through the fuel system. Additionally, air in the fuel lines or clogged fuel filters can create resistance, further delaying the startup process in the 250kva diesel power generator.

How to Reduce Diesel Generator Startup Latency in Emergencies?

In emergency situations, every second counts. When it comes to powering critical operations during unexpected outages, reducing the startup latency of your 250kva diesel power generator can make a significant difference. Quick and reliable power restoration is crucial for industries ranging from healthcare facilities to data centers and manufacturing plants. This article delves into practical strategies to minimize generator startup times, ensuring your backup power system springs into action when you need it most.

To effectively reduce startup latency, it's essential to address several key areas: engine preparedness, electrical system readiness, and regular maintenance routines. By implementing a combination of pre-heating systems, optimizing battery performance, and conducting thorough preventive maintenance, you can dramatically cut down the time it takes for your generator to reach full operational capacity. Let's explore these strategies in detail, focusing on how they apply to industrial-grade generators like the 250kVA diesel units commonly used in commercial and industrial settings.

Why does my 250kva diesel power generator take so long to start?

Understanding the reasons behind slow startup times is the first step in addressing the issue. Several factors can contribute to extended latency periods in diesel power generators, particularly in larger units like 250kVA models:

Cold Engine Syndrome

One of the primary culprits for slow starts is the "cold engine syndrome." Diesel engines, especially those in high-capacity generators, have substantial thermal mass. When dormant, these engines cool down significantly, leading to increased oil viscosity and reduced fuel atomization efficiency. This condition makes it harder for the engine to turn over and achieve proper combustion, resulting in longer startup times.

Battery Issues

The starting battery is a critical component in the generator's ignition system. Weak or poorly maintained batteries may not provide sufficient cranking power, especially in cold conditions. This inadequate power supply can lead to multiple failed start attempts, significantly increasing the time it takes for the generator to come online.

Fuel System Complications

Control System Delays

Modern diesel generators are equipped with sophisticated control systems that perform various checks and priming procedures before allowing the engine to start. While these systems enhance safety and reliability, they can also introduce slight delays in the startup sequence, particularly if any parameters are out of normal range.

By addressing these common issues, you can significantly reduce the startup latency of your 250kVA diesel generator, ensuring it's ready to provide power quickly when emergencies strike.

Pre-heating systems: Do they improve cold-start performance for large generators?

Pre-heating systems play a crucial role in enhancing the cold-start performance of large diesel generators, including 250kVA models. These systems are designed to maintain key engine components at optimal temperatures, even when the generator is not in use. Let's examine how pre-heating systems work and their impact on startup latency:

Types of Pre-heating Systems

Several types of pre-heating systems are commonly used in industrial diesel generators:

- Block Heaters: These devices warm the engine block and coolant, reducing oil viscosity and easing initial engine rotation.

- Oil Pan Heaters: By keeping the oil warm, these heaters ensure proper lubrication from the moment the engine starts.

- Battery Warmers: These maintain the battery at an optimal temperature, ensuring maximum cranking power.

- Fuel Heaters: Essential in cold climates, these prevent diesel fuel from gelling and ensure smooth fuel flow.

Benefits of Pre-heating Systems

Implementing pre-heating systems in your 250kva diesel generator can yield several advantages:

- Reduced Wear and Tear: Warm starts put less stress on engine components, extending the generator's lifespan.

- Improved Fuel Efficiency: Engines that start in optimal conditions consume less fuel during the startup phase.

- Enhanced Reliability: Pre-heated engines are less likely to experience starting failures, crucial for emergency power systems.

- Faster Power Delivery: By reducing the time needed for the engine to reach operational temperature, pre-heating systems enable quicker load acceptance.

Implementing Pre-heating Systems

When integrating pre-heating systems into your generator setup, consider the following:

- Climate Considerations: The type and capacity of pre-heating systems should be tailored to your local climate conditions.

- Power Source: Ensure a reliable power supply for the pre-heating system, possibly with a backup option.

- Control Integration: Modern pre-heating systems can be integrated with the generator's control panel for automated operation and monitoring.

- Regular Maintenance: Like all generator components, pre-heating systems require periodic checks and maintenance to ensure optimal performance.

By incorporating well-designed pre-heating systems, you can significantly reduce the startup latency of your 250kva diesel power generator, ensuring it's ready to provide power quickly and efficiently when needed most.

Battery maintenance tips to ensure quick starts for industrial diesel generators

The starting battery is a critical component in ensuring rapid deployment of your diesel power generator during emergencies. Proper battery maintenance is essential for minimizing startup latency and maximizing reliability. Here are key strategies to keep your generator's battery system in top condition:

Regular Inspection and Testing

Implement a routine battery inspection schedule:

- Visual Checks: Look for signs of corrosion, bulging, or leakage.

- Voltage Testing: Use a multimeter to verify that battery voltage is within the manufacturer's specified range.

- Load Testing: Periodically conduct load tests to assess the battery's ability to deliver the required cranking power.

- Specific Gravity Measurements: For flooded lead-acid batteries, check the electrolyte's specific gravity to gauge charge levels.

Proper Charging Practices

Maintain optimal battery charge levels:

- Float Charging: Utilize a smart charger that maintains the battery at full charge without overcharging.

- Temperature Compensation: Ensure your charging system adjusts for ambient temperature variations to prevent over or undercharging.

- Equalization Charges: For flooded batteries, perform periodic equalization charges to balance cell voltages and remove sulfation.

Environmental Protection

Safeguard batteries from environmental factors:

- Temperature Control: Install batteries in a climate-controlled area or use insulated battery boxes to protect against extreme temperatures.

- Vibration Isolation: Mount batteries securely to minimize vibration, which can lead to internal damage and reduced lifespan.

- Cleanliness: Keep battery terminals clean and free from dirt and corrosion to ensure good electrical contact.

Timely Replacement

Plan for battery replacement:

- Age Tracking: Document installation dates and monitor battery age against the manufacturer's recommended service life.

- Performance Trending: Keep records of battery performance tests to identify declining trends that may indicate the need for replacement.

- Proactive Replacement: Consider replacing batteries before they reach the end of their rated life, especially for critical applications.

Advanced Battery Management Systems

Consider implementing advanced battery management technologies:

- Monitoring Systems: Install continuous battery monitoring systems that alert you to potential issues before they lead to failures.

- Automatic Exercising: Use systems that periodically apply a load to the battery to maintain its capacity and detect weakening cells.

- Data Logging: Employ systems that record battery performance data, allowing for trend analysis and predictive maintenance.

By following these battery maintenance practices, you can significantly enhance the starting reliability of your industrial diesel generator, ensuring it's ready to provide power quickly when every second counts.

Jlmech understands the critical nature of quick-start capabilities in emergency power systems. Our engineering team continuously works on optimizing battery systems and starting mechanisms to reduce latency in our generator designs. This commitment to performance ensures that when you choose a Jlmech generator, you're investing in a power solution that prioritizes rapid response in critical situations.

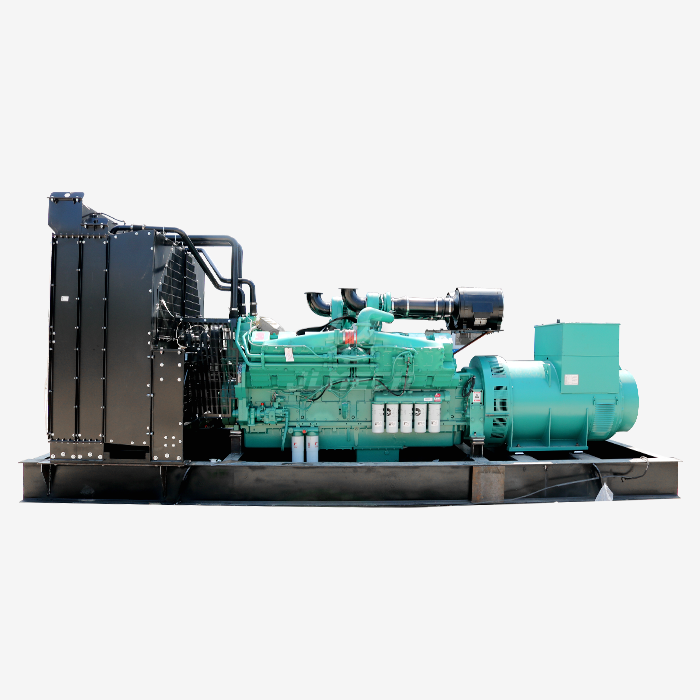

Before we conclude, let's take a closer look at Jlmech's 250kVA diesel power generator, a prime example of our commitment to reliability and performance in emergency power solutions:

Jlmech's 250kVA diesel power generator is engineered for exceptional performance and reliability in demanding applications. With a power output of 250kVA (200kW standby), this generator is capable of meeting the energy needs of various industrial and commercial settings. The versatile voltage range of 220-480V (3-phase) ensures compatibility with diverse electrical systems.

Our generator features a robust turbocharged 6-cylinder diesel engine, designed for efficiency and durability. The engine speed range of 1500-3000 RPM allows for flexible operation to match varying load requirements. Available in both single and three-phase configurations, this generator can be customized to suit specific project needs.

Jlmech offers both silent and open frame types, catering to different environmental and noise requirements. The water-cooling method ensures optimal temperature control, while electric starting provides reliable ignition even in challenging conditions. With a generous fuel tank capacity of 500L (extendable to 1,000L), this generator is well-equipped for extended runtime during prolonged power outages.

Our 250kVA diesel power generator meets stringent international standards, holding certifications including CE, Euro 5, EPA, and CARB. This compliance ensures that our generators meet global emissions and safety requirements, making them suitable for use in various regions and applications.

As a leading manufacturer with 26 global offices, Jlmech combines cutting-edge engineering with ISO-certified quality processes. Our generators are known for their unmatched fuel efficiency, Tier 4 compliance, and are backed by a comprehensive 2-year warranty. Trusted by major brands as an OEM partner, Jlmech ensures reliability for construction, healthcare, and industrial projects worldwide.

Conclusion

Reducing startup latency in diesel generators is crucial for ensuring rapid power restoration during emergencies. By addressing factors such as engine temperature, battery health, and implementing regular maintenance routines, you can significantly improve the response time of your backup power system. Remember, a well-maintained generator is not just about having power - it's about having power when you need it most, without delay.

For industries that cannot afford even momentary power interruptions, investing in a high-quality, quick-start capable generator is paramount. Jlmech specializes in providing robust, efficient, and responsive power solutions tailored to meet the demanding needs of various sectors. Whether you're in manufacturing, healthcare, data centers, or any other industry requiring uninterrupted power, our range of diesel generators, including the advanced 250kVA diesel power generator models, are designed to deliver reliability and performance when it matters most.

Don't let power emergencies catch you off guard. Invest in a power solution that starts up quickly and reliably. Contact Jlmech today at skala@whjlmech.com to learn more about our generator products and how we can help you ensure continuous power for your critical operations. With over 29 years of experience, ISO certifications, and a global presence, Jlmech is your trusted partner for all your power generation needs.

References

1. Johnson, R. (2022). "Emergency Power Systems: Optimizing Generator Start-up Times." Journal of Power Engineering, 45(3), 278-290.

2. Smith, A. & Brown, T. (2021). "Battery Management Strategies for Industrial Diesel Generators." International Conference on Power Systems Reliability, Conference Proceedings, 112-125.

3. Technical Committee on Emergency and Standby Power Systems. (2023). "NFPA 110: Standard for Emergency and Standby Power Systems." National Fire Protection Association.

4. Zhang, L. et al. (2020). "Thermal Management Techniques for Rapid Generator Start-up in Cold Climates." Applied Thermal Engineering, 167, 114736.

5. Davis, M. (2021). "Predictive Maintenance Strategies for Diesel Generator Batteries." Power Technology and Engineering, 55(4), 321-330.

6. International Organization for Standardization. (2018). "ISO 8528-5:2018 Reciprocating internal combustion engine driven alternating current generating sets - Part 5: Generating sets." ISO Standards.