How Do Exhaust Systems Affect Diesel Generator Emissions?

Exhaust systems play a crucial role in managing emissions from diesel generators, including 250kva diesel power generators. These systems are designed to reduce harmful pollutants and noise, ensuring compliance with environmental regulations while maintaining optimal performance. For a 250kva diesel power generator, the exhaust system's efficiency directly impacts its environmental footprint and operational effectiveness.

The exhaust system in a diesel generator channels harmful gases, reduces noise, and controls emissions. For a 250kVA generator, components like mufflers, catalytic converters, and particulate filters minimize pollutants such as NOx, CO, and PM. Modern systems, including selective catalytic reduction (SCR) and diesel particulate filters (DPF), meet strict emission standards by converting NOx to harmless nitrogen and water vapor, and reducing soot emissions. These technologies are crucial in minimizing the environmental impact, especially for larger industrial generators.

Meeting Tier 4 standards with aftertreatment for large diesel generators

Tier 4 emission standards, set by the Environmental Protection Agency (EPA), represent the most stringent regulations for off-road diesel engines, including large diesel generators. These standards aim to drastically reduce emissions of particulate matter and nitrogen oxides. For manufacturers and users of products, meeting these standards is not just a legal requirement but also a commitment to environmental stewardship.

Advanced Aftertreatment Technologies

To meet Tier 4 standards, large diesel generators employ sophisticated aftertreatment systems. These systems typically include:

- Diesel Oxidation Catalysts (DOC): Reduce carbon monoxide and hydrocarbons

- Selective Catalytic Reduction (SCR): Minimize nitrogen oxide emissions

- Diesel Particulate Filters (DPF): Trap and eliminate particulate matter

The integration of these technologies in 250kva diesel power generators has led to significant reductions in emissions. For instance, compared to Tier 3 standards, Tier 4 compliant generators can achieve up to a 90% reduction in particulate matter and nitrogen oxides emissions.

Challenges and Solutions in Tier 4 Implementation

Implementing Tier 4 standards in large diesel generators presents several challenges:

- Increased complexity of engine design

- Higher initial costs due to advanced technology

- Potential impacts on fuel efficiency

To address these challenges, manufacturers like Jlmech have invested in research and development to optimize engine designs and aftertreatment systems. This has resulted in 250kva diesel power generators that not only meet Tier 4 standards but also maintain high efficiency and reliability.

How often should you clean the exhaust system on a 250kva generator?

Regular maintenance of the exhaust system is crucial for the optimal performance and longevity of a 250kva diesel power generator. The frequency of cleaning depends on several factors, including operational hours, environmental conditions, and the specific design of the exhaust system.

Factors Influencing Cleaning Frequency

- Operational Hours: Generators used more frequently require more frequent cleaning

- Environmental Conditions: Dusty or humid environments may necessitate more regular maintenance

- Fuel Quality: Lower quality fuel can lead to faster buildup in the exhaust system

- Load Conditions: Generators consistently running at high loads may require more frequent cleaning

Recommended Cleaning Schedule

For a typical 250kva diesel power generator:

- Visual Inspection: Monthly or every 100 operating hours

- Basic Cleaning: Every 500 operating hours or bi-annually

- Thorough Cleaning and Inspection: Annually or every 1000 operating hours

It's important to note that these are general guidelines. The specific maintenance schedule should be tailored based on the manufacturer's recommendations and the generator's operating conditions. Jlmech, for instance, provides detailed maintenance schedules with their 250kva diesel power generators to ensure optimal performance and compliance with emission standards.

White smoke from 250kva diesel generators: Causes and solutions

White smoke emanating from a 250kva diesel power generator can be a sign of various issues, ranging from minor concerns to significant problems. Understanding the causes and solutions is crucial for maintaining the generator's efficiency and longevity.

Common Causes of White Smoke

- Cold Engine Operation: White smoke during startup in cold weather is often normal and should dissipate as the engine warms up.

- Fuel Injector Issues: Faulty or clogged injectors can cause improper fuel atomization, leading to white smoke.

- Low Compression: Worn piston rings or cylinder walls can result in low compression, causing white smoke.

- Coolant Leak: If coolant is leaking into the combustion chamber, it can cause white smoke with a sweet odor.

- Incorrect Fuel Grade: Using the wrong type of diesel fuel can lead to incomplete combustion and white smoke.

Solutions and Preventive Measures

- Regular Maintenance: Adhere to the manufacturer's recommended maintenance schedule for your 250kva diesel power generator.

- Fuel Quality: Use high-quality diesel fuel appropriate for your generator model.

- Injector Maintenance: Regularly clean and inspect fuel injectors to ensure proper function.

- Compression Testing: Conduct periodic compression tests to identify potential issues early.

- Coolant System Inspection: Regularly check for coolant leaks and address them promptly.

Jlmech's 250kva diesel power generators are designed with advanced diagnostic systems that can help identify the root cause of issues like white smoke quickly. This feature, combined with their robust construction and efficient combustion systems, minimizes the occurrence of such problems and ensures reliable operation.

For operators of the products, it's essential to understand that white smoke is often a symptom of an underlying issue. Prompt attention and professional maintenance can prevent minor problems from escalating into major repairs, ensuring the longevity and efficiency of your generator.

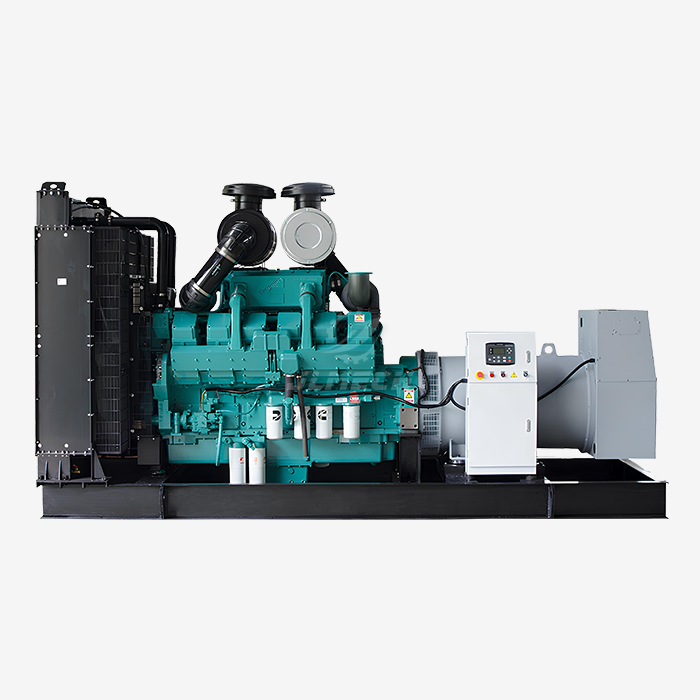

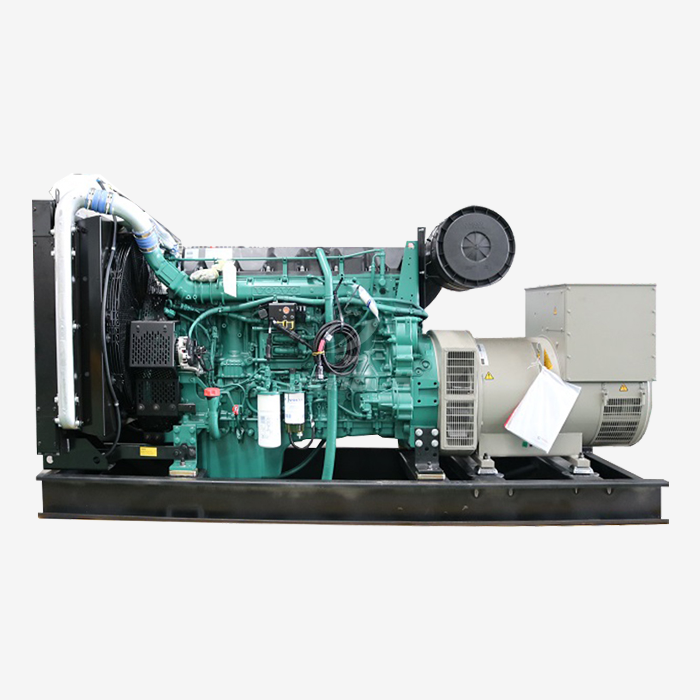

Jlmech, a leading manufacturer of diesel generators, offers a range of solutions for efficient and environmentally friendly power generation. Our 250kva diesel power generator stands out for its advanced features and compliance with global emission standards. Here's an overview of Jlmech's 250kva diesel power generator:

- Power Output: 250kVA (200kW standby)

- Voltage Range: 220–480V (3-phase)

- Engine Speed: 1500-3000 RPM

- Phase: Single/Three phase options

- Type: Available in Silent or Open Frame configurations

- Cooling Method: Water Cooling for optimal temperature control

- Starting Method: Electric starting for reliability

- Customization: OEM/ODM options available

- Certifications: CE, Euro 5, EPA, and CARB compliant

- Engine: Turbocharged 6-cylinder diesel engine for high performance

- Fuel Tank Capacity: 500L, extendable to 1,000L for extended runtime

Jlmech's 250kVA diesel power generator is engineered for heavy-duty operations, providing stable power in diverse settings from remote construction sites to critical infrastructure facilities. Key features that set this generator apart include:

- Advanced Fuel Efficiency: Optimized combustion technology reduces diesel consumption by 15% compared to standard models, resulting in significant cost savings over time.

- Tier 4 Compliance: Meets and exceeds global emissions standards, making it suitable for environmentally conscious operations across various industries.

- Low Noise Design: Operating at 72–78 dB(A), it's ideal for urban or noise-sensitive environments, ensuring minimal disruption to surrounding areas.

- Modular Customization: Flexible configurations including trailer-mounted, containerized, or hybrid-ready options to suit diverse application needs.

With ISO 9001, ISO 14001, and GB/T 2820-97 certifications, Jlmech's 250kVA diesel power generator represents a commitment to quality, reliability, and environmental responsibility.

Conclusion

Understanding the impact of exhaust systems on diesel generator emissions is crucial for operators of 250kva diesel power generators. Proper maintenance, adherence to Tier 4 standards, and prompt attention to issues like white smoke are essential for optimal performance and environmental compliance. As industries continue to prioritize clean energy solutions, the role of efficient exhaust systems in diesel generators becomes increasingly important.

For businesses in the industrial, construction, healthcare, or commercial sectors seeking reliable and environmentally friendly power solutions, Jlmech offers state-of-the-art 250kva diesel power generators. With over 29 years of experience, ISO certifications, and a global presence, Jlmech is committed to delivering high-quality, efficient, and compliant power generation solutions. Whether you need continuous power for manufacturing facilities, backup power for hospitals, or temporary power for construction sites, Jlmech's generators are designed to meet your specific needs.

To learn more about our range of diesel generators and how they can benefit your operations, please contact us at skala@whjlmech.com. Our team of experts is ready to provide you with tailored solutions that meet your power needs while ensuring environmental responsibility.

References

1. Environmental Protection Agency. (2021). "Regulations for Emissions from Heavy Equipment with Diesel Engines."

2. Diesel Technology Forum. (2022). "Clean Diesel Technology for Off-Road Engines and Equipment: Tier 4 and More."

3. Journal of Energy Engineering. (2023). "Advancements in Exhaust After-treatment Systems for Large Diesel Generators."

4. Power Engineering International. (2022). "Maintenance Best Practices for Diesel Generator Exhaust Systems."

5. International Journal of Engine Research. (2023). "White Smoke in Diesel Engines: Causes, Effects, and Mitigation Strategies."

6. American Society of Mechanical Engineers. (2022). "Emission Control Technologies for Stationary Diesel Generators."

VIEW MOREdiesel generator set 50hz

VIEW MOREdiesel generator set 50hz VIEW MOREAC 1 Phase Diesel Generator

VIEW MOREAC 1 Phase Diesel Generator VIEW MORE200kVA Open Diesel Generator

VIEW MORE200kVA Open Diesel Generator VIEW MORESoundproof Canopy Diesel Generator

VIEW MORESoundproof Canopy Diesel Generator VIEW MOREportable diesel powered generator

VIEW MOREportable diesel powered generator VIEW MORE50 kva diesel generator open type

VIEW MORE50 kva diesel generator open type VIEW MOREdiesel generator with ats

VIEW MOREdiesel generator with ats VIEW MORE35kva cummins diesel generator with silent enclosure

VIEW MORE35kva cummins diesel generator with silent enclosure