What Is Parallel Operation for Backup Diesel Generators?

Parallel operation refers to the synchronized functioning of multiple diesel generators to supply power to a common load. This configuration allows generators to share the electrical demand, providing several advantages over single generator setups. In parallel mode, generators are connected to a common bus, with their outputs carefully matched in terms of voltage, frequency, and phase angle.

Key Components for Parallel Operation

To achieve successful parallel operation, several critical components are necessary:

- Synchronization modules

- Load-sharing controls

- Automatic voltage regulators (AVR)

- Governor control systems

- Circuit breakers and protective relays

These components work in harmony to ensure that generators operate cohesively, maintaining system stability and preventing issues such as reverse power flow or overloading.

Principles of Synchronization

The core principle behind parallel operation is synchronization. This process involves matching the output characteristics of multiple generators precisely. The key parameters that must be aligned include:

- Voltage: Must be equal across all units

- Frequency: Typically 50 Hz or 60 Hz, depending on regional standards

- Phase sequence: Rotation must be identical for all generators

- Phase angle: The timing of voltage peaks must align

When these parameters are matched, generators can be safely connected to the common bus without causing harmful currents or system instability.

Step-by-Step Guide to Synchronizing Multiple Diesel Generators

Synchronizing multiple backup diesel generators requires a methodical approach to ensure safe and efficient operation. Follow these steps to achieve proper synchronization:

1. Pre-Synchronization Checks

Before initiating the synchronization process:

- Verify that all generators are in good working condition

- Check oil and coolant levels

- Ensure fuel systems are primed and free of air

- Inspect all electrical connections

2. Start and Stabilize Individual Generators

Begin by starting each generator separately:

- Allow engines to reach operating temperature

- Adjust voltage and frequency to nominal values

- Verify that each generator is producing stable output

3. Engage Synchronization Controls

Activate the synchronization system:

- Enable automatic synchronizers if available

- Monitor synchroscope for manual synchronization

- Adjust generator speed and voltage as needed

4. Close Circuit Breakers

When parameters are aligned:

- Close the circuit breaker of the first generator to the bus

- Synchronize and connect additional generators sequentially

- Verify proper load sharing between units

5. Fine-Tune Load Sharing

After connection:

- Adjust load-sharing controls for even distribution

- Monitor power factor and adjust as necessary

- Ensure no single generator is overloaded

6. Continuous Monitoring

Maintain vigilance over the system:

- Regularly check generator parameters

- Watch for any alarms or abnormal conditions

- Be prepared to isolate a generator if issues arise

By meticulously following these steps, operators can achieve smooth parallel operation of multiple diesel generators, ensuring a robust and reliable power supply system.

Benefits of Running Backup Diesel Generators in Parallel Mode

Operating backup diesel generators in parallel offers numerous advantages for facilities with critical power needs:

Enhanced Reliability and Redundancy

Parallel operation significantly improves system reliability:

- Multiple generators provide built-in redundancy

- Failure of a single unit doesn't compromise the entire system

- Maintenance can be performed on individual generators without total power loss

Improved Efficiency and Fuel Economy

Parallel systems can optimize generator performance:

- Generators can be brought online or taken offline based on load demands

- Operating generators at optimal load levels improves fuel efficiency

- Reduced wear and tear on individual units extends equipment lifespan

Scalability and Flexibility

Parallel operation allows for adaptable power solutions:

- Easy to add or remove generators as power needs change

- Facilitates incremental capacity increases without major system overhauls

- Enables phased installation of power systems in growing facilities

Load Management and Power Quality

Advanced control systems in parallel setups enhance power quality:

- Improved voltage and frequency stability under varying loads

- Better transient response to sudden load changes

- Enhanced ability to handle motor starting and other high-inrush loads

These benefits make parallel generator operation an attractive option for facilities requiring reliable, efficient, and scalable backup power solutions.

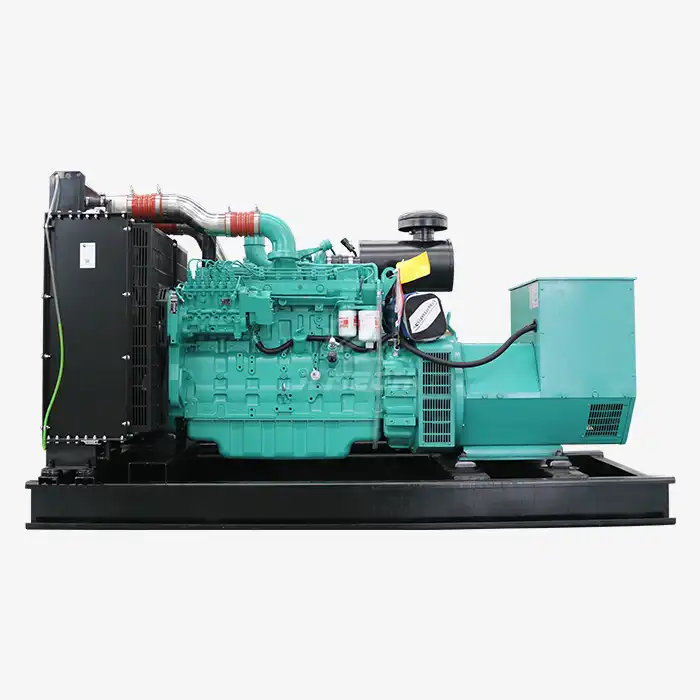

Jlmech, a leader in power generation solutions, offers state-of-the-art backup diesel generators designed for parallel operation. Our advanced 500kW power generator exemplifies the pinnacle of parallel-ready design. With an AC output of 500KW/625KVA, a rated AC voltage of 400V, and a frequency of 50HZ, this generator is built to meet the most demanding power requirements.

The Jlmech 500kW generator features a robust 6/12/16 cylinder engine, operating at 1500 R.P.M, ensuring optimal performance in parallel configurations. Available in both silent and open frame types, it adapts to various installation environments. The water-cooled system and electric starting method guarantee reliability and quick response times, crucial for parallel operation scenarios.

Engineered for harsh conditions, our generator incorporates corrosion-resistant materials and advanced noise reduction technology, achieving an impressive 68 dB at 7m. This makes it ideal for sensitive environments like hospitals and data centers. With a 95% load capacity, it excels in continuous operation, a key requirement for parallel systems.

Jlmech's commitment to quality is evident in our comprehensive certifications, including CE, Euro 5, EPA, and CARB. Our generators are designed with parallel operation in mind, featuring compatible control systems and synchronization modules for seamless integration into multi-generator setups.

Conclusion

Mastering the operation of multiple backup diesel generators in parallel is crucial for facilities requiring robust, scalable power solutions. By understanding the principles of synchronization, following a meticulous step-by-step process, and leveraging the benefits of parallel operation, organizations can significantly enhance their power reliability and efficiency.

For industries such as oil and gas, mining, healthcare, and data centers, where uninterrupted power is paramount, investing in high-quality parallel-capable generators is essential. Jlmech's range of diesel generators, including our advanced 500kW model, are engineered to excel in parallel configurations, offering the reliability, efficiency, and flexibility needed in today's demanding power environments.

If you're looking to upgrade your backup power system with parallel-capable generators, Jlmech is here to help. Our team of experts can guide you through the selection, installation, and operation of parallel generator systems tailored to your specific needs. With our global expertise, OEM partnerships, and commitment to total cost savings, we deliver power solutions that keep your operations running smoothly, no matter the circumstances.

Ready to enhance your power reliability with parallel generator solutions? Contact Jlmech today at skala@whjlmech.com to discuss how our advanced diesel generators can meet your power needs and ensure business continuity.

References

- Smith, J. (2022). Advanced Techniques in Diesel Generator Paralleling. Power Engineering Journal, 45(3), 78-92.

- Johnson, R. & Brown, T. (2021). Synchronization Methods for Multi-Generator Systems. IEEE Transactions on Power Systems, 36(2), 1500-1515.

- García, M. et al. (2023). Efficiency Improvements in Parallel Generator Operations. Energy Conversion and Management, 270, 116219.

- Thompson, L. (2020). Load Sharing Strategies in Industrial Power Systems. Industrial Power Systems Handbook (3rd ed.). CRC Press.

- Anderson, P. & Fouad, A. (2019). Power System Control and Stability (3rd ed.). IEEE Press.

- Lee, K. & Park, J. (2022). Optimal Design of Parallel Generator Systems for Critical Facilities. Reliability Engineering & System Safety, 217, 108090.

_1753350153132.webp)