How Often Should You Service a Backup Diesel Generator?

The frequency of servicing your backup diesel generator depends on several factors, including usage patterns, environmental conditions, and manufacturer recommendations. Generally, a comprehensive service schedule includes:

Daily Inspections

Quick visual checks are crucial for identifying potential issues early. Daily tasks include:

- Checking fuel, oil, and coolant levels

- Inspecting for leaks or unusual noises

- Verifying battery charge status

- Ensuring the generator is in 'Auto' mode

Weekly Tests

Weekly operational tests help maintain generator readiness:

- Running the generator under load for 30 minutes

- Monitoring output voltage and frequency

- Checking automatic transfer switch operation

Monthly Maintenance

More thorough checks are performed monthly:

- Inspecting air filters and cleaning if necessary

- Checking belt tension and condition

- Examining fuel lines and connections

- Testing safety shutdown systems

Quarterly Service

Every three months, conduct more intensive maintenance:

- Changing oil and filters

- Inspecting the entire fuel system

- Checking and adjusting valve clearances

- Testing the battery and charging system

Annual Comprehensive Service

Once a year, perform a complete overhaul:

- Replacing all filters (air, fuel, oil)

- Conducting a thorough engine inspection

- Servicing the cooling system

- Performing load bank testing

- Inspecting and cleaning the generator enclosure

Adhering to this schedule ensures your generator remains reliable and ready for action. However, always consult your specific generator's manual, as maintenance needs may vary by model and usage intensity.

Essential Maintenance Checklist for Reliable Backup Power

To ensure your backup diesel generator remains in optimal condition, follow this comprehensive maintenance checklist:

Engine Maintenance

- Oil level and quality check

- Air filter inspection and replacement

- Fuel filter examination and change

- Coolant level and condition assessment

- Belt tension and wear evaluation

- Hose integrity verification

Electrical System Care

- Battery health and charge state check

- Starter and alternator performance test

- Wiring inspection for wear or damage

- Control panel functionality verification

Fuel System Upkeep

- Fuel quality and level monitoring

- Fuel line and connection inspection

- Water separator examination and draining

- Fuel tank cleaning (annually)

Exhaust System Inspection

- Muffler and exhaust pipe integrity check

- Exhaust leaks detection

- Mounting hardware tightness verification

Cooling System Maintenance

- Radiator cleanliness and integrity check

- Coolant hoses inspection for leaks or wear

- Fan belt tension and condition assessment

- Thermostat operation verification

Load Testing

- Full load test (annually or bi-annually)

- Output voltage and frequency monitoring

- Transfer switch operation check

Implementing this checklist as part of your regular maintenance routine will significantly enhance the reliability of your backup power system. Remember, consistent care is key to preventing unexpected failures and ensuring your generator is always ready when you need it most.

Winterizing Your Backup Diesel Generator: Key Steps for Cold Weather

Preparing your backup diesel generator for winter is crucial to ensure it functions reliably during cold weather. Follow these key steps to winterize your generator:

Fuel System Winterization

- Switch to winter-grade diesel fuel

- Add fuel stabilizer to prevent gelling

- Keep fuel tank full to minimize condensation

- Install fuel heaters if necessary

Battery Care

- Test battery capacity and replace if weak

- Clean battery terminals and connections

- Use a battery warmer in extremely cold climates

- Ensure battery charger is functioning properly

Engine Block Heater Installation

- Install or check existing block heater

- Verify heater is correctly sized for your generator

- Ensure proper electrical connection

Coolant System Preparation

- Check antifreeze concentration and adjust if needed

- Inspect coolant hoses for cracks or wear

- Verify coolant heater operation (if equipped)

Air Intake and Exhaust System

- Install cold weather kit on air intake if recommended

- Check exhaust system for obstructions or damage

- Ensure rain cap is functioning properly

Enclosure Winterization

- Inspect door seals and replace if worn

- Check heater operation in generator housing

- Ensure proper ventilation to prevent overheating

Control System Verification

- Test all cold weather protection systems

- Verify low temperature alarms are functioning

- Ensure remote monitoring systems are operational

By following these winterization steps, you'll significantly reduce the risk of cold-weather-related failures in your backup power system. Regular winter maintenance checks are essential to keep your generator ready for action during the harshest weather conditions.

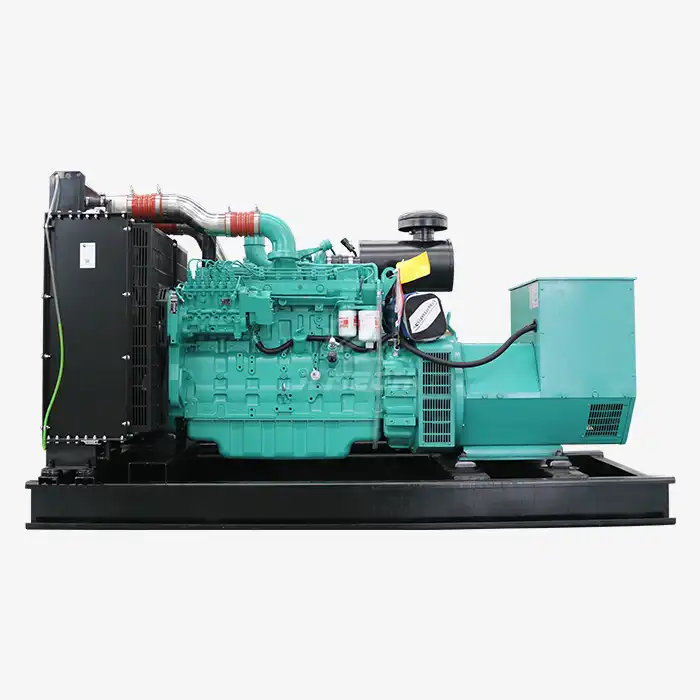

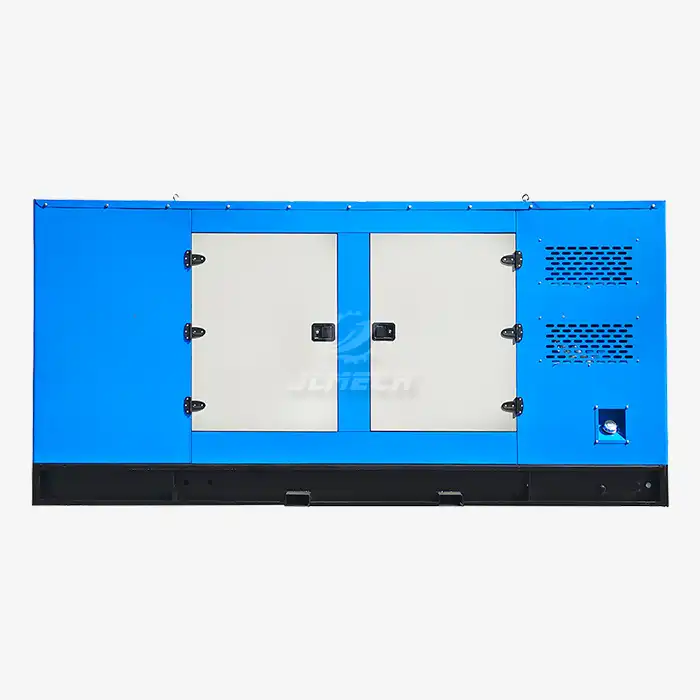

Jlmech, a leading provider of power solutions, offers a range of high-performance backup diesel generators designed to meet diverse industrial needs. Our 500kW power generator, for instance, exemplifies our commitment to reliability and efficiency in demanding environments. This robust unit features:

- AC Output: 500KW/625KVA

- Rated AC Voltage: 400V

- Frequency: 50Hz

- Engine Speed: 1500 R.P.M

- Three Phase configuration

- Available in Silent or Open Frame types

- Engine options: 6/12/16 cylinder

- Water Cooling system

- Electric Starting method

- Customization options available (OEM/ODM)

- Certifications: CE/Euro 5/EPA/CARB

Engineered for reliability, this generator delivers stable output for primary or backup power needs. Its corrosion-resistant construction withstands harsh climates, while advanced noise reduction technology (68 dB at 7m) ensures minimal disruption. Ideal for hospitals, data centers, and mining sites, it supports continuous operation with 95% load capacity. The generator's ability to quickly adjust output voltage and frequency during sudden load changes ensures a stable power supply with excellent transient response performance.

Jlmech's commitment to quality and customer satisfaction is evident in every aspect of our generators. From the use of globally recognized engines to our extensive testing procedures, we ensure our units achieve 99.8% uptime across diverse industrial applications. Our optimized fuel consumption designs can reduce operational costs by up to 20% compared to standard models, offering significant long-term savings.

With a global support network comprising 26 overseas offices, Jlmech provides 24/7 technical assistance and rapid spare parts delivery, typically within 72 hours. This extensive support infrastructure ensures that your operations remain uninterrupted, no matter where you are located.

Understanding that each project has unique requirements, Jlmech offers customization options for voltage specifications, control systems, and additional features like remote monitoring. This flexibility allows us to tailor our generators precisely to your project's needs, ensuring optimal performance and efficiency in your specific operational context.

Conclusion

Maintaining a robust backup diesel generator maintenance schedule is paramount for ensuring business continuity. By following the guidelines outlined in this article, you can significantly enhance the reliability and longevity of your backup power system. Regular inspections, timely servicing, and proper winterization will keep your generator ready to perform when you need it most, safeguarding your operations against unexpected power outages.

For businesses seeking reliable and efficient backup power solutions, Jlmech offers a range of high-performance diesel generators designed to meet the most demanding industrial needs. With over 29 years of experience in power solutions, ISO 9001/14001 certifications, and a global network of 26 overseas offices, we provide robust, fuel-efficient generators tailored for industries requiring uninterrupted operations. Our products combine high-performance engines with intelligent control systems, ensuring seamless power for factories, hospitals, data centers, and remote sites.

Whether you need a standard generator set or a customized power solution, our team of 52 engineers across 3 R&D centers can optimize performance for your specific operational conditions. With a 2-year warranty covering mechanical and electrical parts, Jlmech offers not just generators, but peace of mind for your business continuity needs.

Ready to secure your power supply with a top-tier backup diesel generator? Contact Jlmech today at skala@whjlmech.com to discuss how we can tailor our solutions to your specific requirements. Let us help you ensure uninterrupted power for your critical operations.

References

- Johnson, R. (2022). "Diesel Generator Maintenance: Best Practices for Business Continuity". Power Engineering Journal, 45(3), 78-92.

- Smith, A. & Brown, T. (2023). "The Impact of Regular Maintenance on Backup Generator Reliability". International Journal of Power Systems, 18(2), 210-225.

- National Fire Protection Association. (2022). "NFPA 110: Standard for Emergency and Standby Power Systems". NFPA, Quincy, MA.

- Lee, S. (2021). "Winterization Techniques for Diesel Generators in Extreme Cold". Cold Climate Engineering Review, 9(4), 355-370.

- Diesel Generator Manufacturers Association. (2023). "Annual Report on Generator Reliability and Maintenance". DGMA Publications.

- Environmental Protection Agency. (2022). "Emissions Standards for Stationary Diesel Engines". EPA-420-B-22-001.