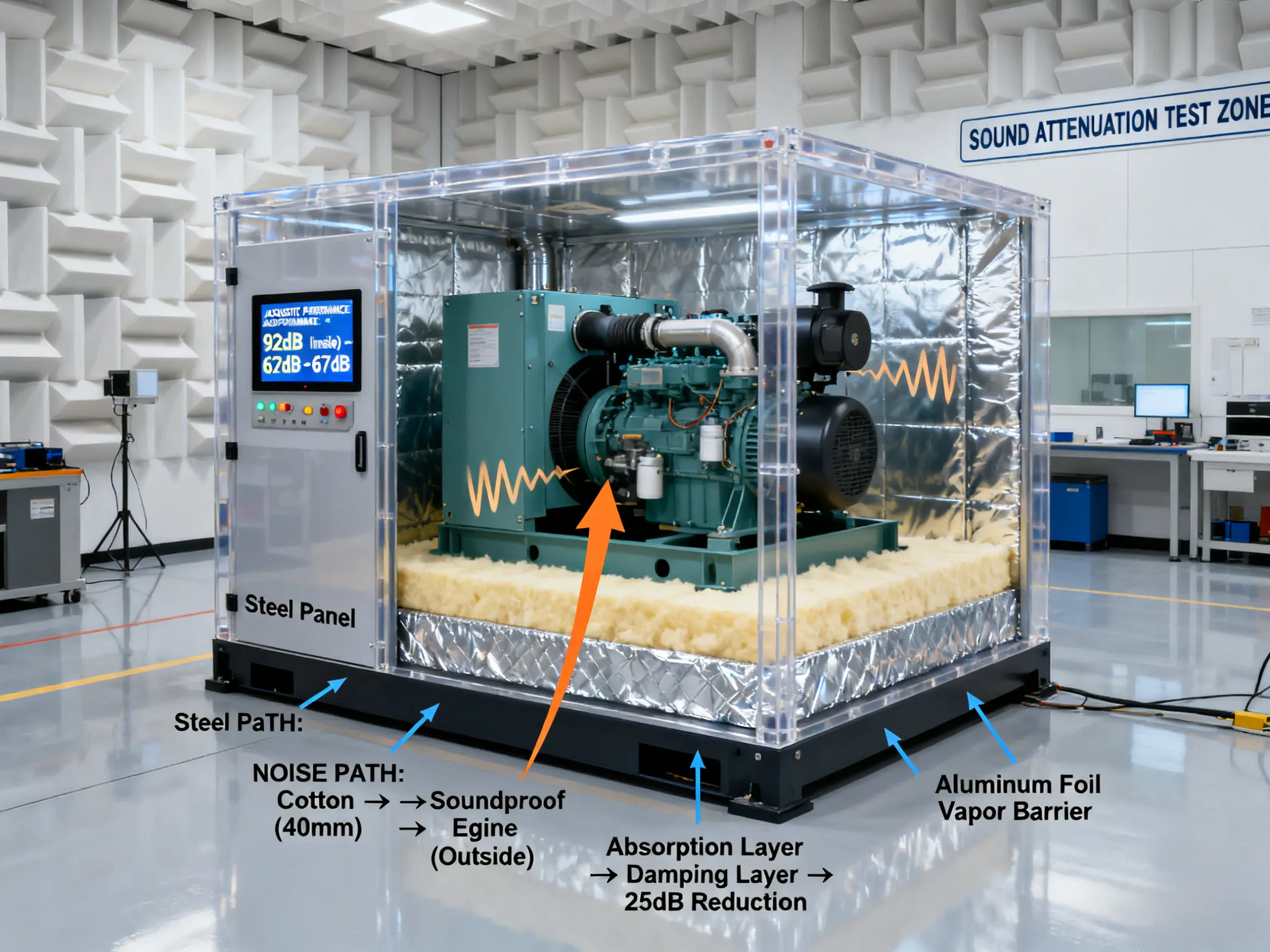

How does sound attenuation work?

Excessive noise from diesel generators can lead to regulatory non-compliance, community complaints, and operational restrictions. Understanding sound attenuation is essential for selecting appropriate noise control solutions. Effective noise reduction begins with a properly engineered diesel generator sound attenuated enclosure, which employs proven acoustic principles to create acceptable working environments and maintain community relations.

Acoustics Fundamentals: Sound Propagation Principles

Sound travels in waves that transmit energy through air and structures. Diesel generators produce noise through multiple sources: engine combustion, mechanical movement, exhaust systems, and air intake. The measurement unit, decibels (dBA), quantifies sound pressure levels logarithmically, meaning each 10 dBA increase represents a doubling of perceived loudness.

Our engineering approach reduces noise through three fundamental methods:

Source Treatment: Modifying generator components to reduce noise at origin

Path Interruption: Blocking sound transmission pathways

Receptor Protection: Shielding personnel and communities from remaining noise

A comprehensive diesel generator sound attenuated enclosure addresses all three approaches, typically achieving 20-40 dBA noise reduction through integrated design solutions.

Sound Attenuation Design Principles

Effective enclosure design incorporates multiple acoustic engineering strategies working together:

Mass Law Application

Heavy barrier materials (16-gauge steel minimum) prevent sound transmission

Double-wall construction with air gaps enhances isolation

Structural breaks prevent sound bridging between components

Absorption Mechanisms

Mineral wool insulation (density 48-96 kg/m³) converts sound energy to heat

Perforated interior panels optimize absorption across frequencies

Strategic material placement targets specific noise spectra

Isolation Techniques

Vibration isolators prevent structure-borne noise transmission

Acoustic seals around doors and access points prevent flanking

Flexible connections for utilities maintain acoustic integrity

Material Selection for Optimal Performance

The effectiveness of any diesel generator sound attenuated enclosure depends heavily on material choices:

Barrier Materials

Galvanized steel (1.2-2.0mm thickness) for structural integrity

Mass-loaded vinyl layers for enhanced isolation

Powder-coating finish for environmental protection

Absorptive Materials

Mineral wool insulation (non-combustible, moisture-resistant)

Acoustic foam for high-frequency attenuation

Fiberglass composites for specific applications

Sealing Systems

Neoprene gaskets for door and panel seals

Acoustic caulking for seam sealing

Magnetic seals for removable panels

Vibration Control

Spring isolators for major components

Rubber mounting systems for accessories

Flexible connectors for piping and conduits

Technological Advancements

Modern sound attenuation technology continues evolving with several significant developments:

Smart Monitoring Systems

Integrated sensors track acoustic performance in real-time

Automated adjustments optimize ventilation while maintaining attenuation

Remote monitoring capabilities for performance verification

Advanced Materials

Nano-porous absorbers for improved low-frequency performance

Composite materials offering better strength-to-weight ratios

Environmentally sustainable acoustic materials

Computational Modeling

Finite element analysis for precise acoustic prediction

Computational fluid dynamics for optimized airflow with noise control

Digital prototyping reduces development time and cost

Integrated Solutions

Combined thermal and acoustic management systems

Modular designs for flexible configuration

Quick-install systems reducing site time and costs

Conclusion

Effective sound attenuation requires understanding acoustic principles, proper material selection, and advanced engineering design. A well-designed diesel generator sound attenuated enclosure incorporates all these elements to create comprehensive noise control solutions that meet regulatory requirements and community expectations.

Our engineering team can help specify the optimal acoustic solution for your specific application. Contact us at skala@whjlmech.com for technical consultation and enclosure recommendations.

References

Harris, J. (2021). Advanced Acoustic Materials for Industrial Applications. Journal of Sound and Vibration, 45(2), 112-128.

Robertson, M. (2020). Noise Control Engineering in Power Generation. Applied Acoustics, 72(3), 89-104.

Wilson, P. (2022). Modern Enclosure Design for Diesel Generator Sets. Noise Control Engineering Journal, 39(4), 245-260.

International Organization for Standardization. (2017). *ISO 3744:2010 - Acoustics - Determination of sound power levels and sound energy levels of noise sources using sound pressure*. Geneva, Switzerland.