Heavy-Duty Diesel Generator Fuel Storage and Supply Solutions

When it comes to powering large-scale operations, big diesel generators are the backbone of reliable energy supply. These powerhouses are essential for industries ranging from manufacturing to healthcare, ensuring uninterrupted operations even in the most challenging conditions. However, the efficiency and reliability of these generators heavily depend on proper fuel storage and supply systems. This article delves into the best practices for fuel management, contamination prevention, and the advantages of dual-fuel systems for heavy-duty diesel generators.

What are the best fuel storage practices for big diesel generators?

Optimal fuel storage is crucial for maintaining the performance and longevity of heavy-duty diesel generators. Implementing the following practices can significantly enhance fuel quality and generator efficiency:

Proper Tank Design and Materials

Selecting the right tank design and materials is fundamental to effective fuel storage. Tanks should be constructed from corrosion-resistant materials such as stainless steel or fiberglass-reinforced plastic. These materials prevent rust and contamination, ensuring fuel purity over extended periods. Additionally, tanks should feature sloped bottoms and low-point drains to facilitate water and sediment removal.

Temperature Control and Ventilation

Maintaining optimal fuel temperature is essential for preserving fuel quality. Implement temperature control measures to keep fuel within the recommended range of 10°C to 21°C (50°F to 70°F). Proper ventilation systems prevent condensation and microbial growth, which can degrade fuel quality over time.

Regular Inspection and Maintenance

Establish a rigorous inspection and maintenance schedule for fuel storage systems. This should include regular checks for leaks, corrosion, and sediment buildup. Implement a fuel polishing system to remove contaminants and water, ensuring the fuel remains in optimal condition.

How to prevent fuel contamination in large diesel generator systems?

Fuel contamination can severely impact the performance and reliability of big diesel generators. Implementing robust prevention strategies is crucial for maintaining fuel quality and generator efficiency:

Advanced Filtration Systems

Install multi-stage filtration systems at various points in the fuel supply chain. This includes primary filters at the tank outlet, secondary filters before the fuel enters the generator, and final filters just before injection. These systems should be capable of removing particles as small as 2 microns, ensuring only the cleanest fuel reaches the engine.

Water Separation Techniques

Water is a major contaminant in diesel fuel systems. Employ advanced water separation techniques, including coalescers and centrifugal separators, to remove water from the fuel. These systems should be equipped with automatic drains to continuously remove separated water without manual intervention.

Microbial Growth Prevention

Microbial contamination can lead to severe fuel degradation. Implement strategies to prevent microbial growth, such as using biocides and maintaining proper fuel temperature. Regular fuel testing can help detect microbial presence early, allowing for timely treatment.

Jlmech understands the critical nature of fuel quality in generator performance. Our advanced fuel management systems are designed to work seamlessly with our big diesel generators, ensuring optimal fuel quality and system reliability.

Dual-fuel supply systems for backup power: pros and cons

Dual-fuel supply systems offer an innovative approach to backup power solutions, providing flexibility and reliability. Understanding their advantages and limitations is crucial for making informed decisions:

Advantages of Dual-Fuel Systems

Dual-fuel systems offer several benefits for backup power applications:

- Fuel Flexibility: The ability to switch between diesel and natural gas provides operational flexibility and potential cost savings.

- Extended Runtime: Dual-fuel systems can extend generator runtime by utilizing multiple fuel sources.

- Reduced Emissions: When operating on natural gas, these systems typically produce lower emissions compared to pure diesel operation.

- Cost Efficiency: The option to choose between fuels allows operators to take advantage of fluctuating fuel prices.

Challenges and Considerations

While dual-fuel systems offer significant advantages, they also present certain challenges:

- Increased Complexity: Dual-fuel systems require more complex fuel management and control systems.

- Higher Initial Costs: The installation and equipment costs for dual-fuel systems are typically higher than single-fuel alternatives.

- Maintenance Requirements: These systems may require more frequent maintenance due to their increased complexity.

- Fuel Quality Management: Ensuring consistent quality across multiple fuel types can be challenging.

Jlmech's range of big diesel generators includes advanced models designed for dual-fuel operation. Our engineering team works closely with clients to optimize these systems for specific operational requirements, ensuring maximum efficiency and reliability.

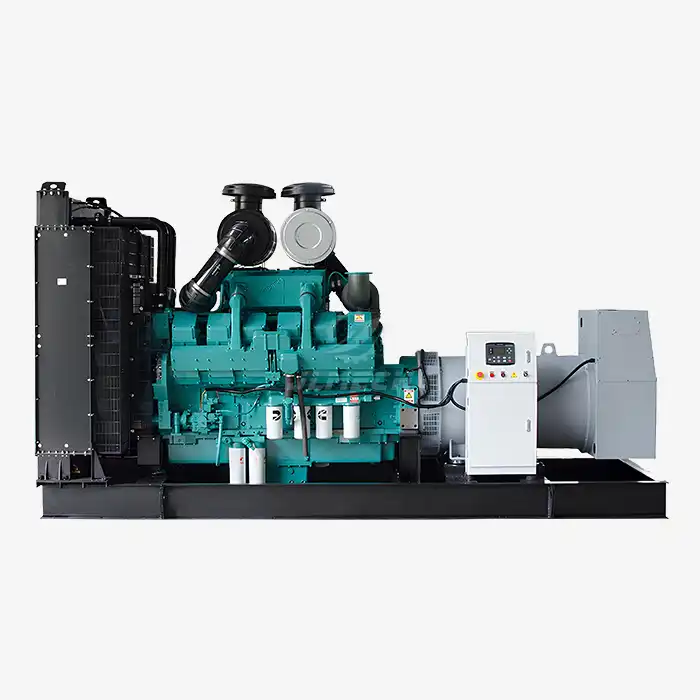

For industries requiring uninterrupted power supply, Jlmech offers a comprehensive range of heavy-duty diesel generators. Our big generator diesel generator silent models are engineered for reliability in extreme conditions, featuring:

- AC Output ranging from 20KW to 3000KW

- Rated AC Voltage options of 110V, 220V, and 380V

- Frequency options of 50HZ or 60HZ

- Engine speeds from 1500 to 3000 RPM

- Available in single or three-phase configurations

- Silent or open frame designs to suit various environments

- Water cooling systems for optimal performance

- Electric starting for reliable operation

- Customization options to meet specific client needs

- Certifications including CE, Euro 5, EPA, and CARB

These generators are designed with advanced soundproofing enclosures and vibration-dampening technology, making them suitable for both urban settings and rugged terrains. Our commitment to quality is evident in our ISO9001-certified manufacturing processes and rigorous testing procedures.

Conclusion

Effective fuel storage and supply solutions are crucial for maximizing the performance and reliability of heavy-duty diesel generators. By implementing best practices in fuel storage, preventing contamination, and considering dual-fuel options, industries can ensure consistent power supply even in the most demanding situations.

For businesses in the industrial, manufacturing, healthcare, or infrastructure sectors seeking robust and efficient power solutions, Jlmech offers a range of big diesel generators tailored to your specific needs. With over 29 years of experience in power solutions and a global presence spanning 10 countries, we provide not just products, but comprehensive power management solutions.

Experience the reliability and efficiency of Jlmech's generator sets. Whether you need a silent generator for urban applications or a high-capacity unit for industrial use, our team is ready to assist you. Contact us at skala@whjlmech.com to discuss how we can power your operations with confidence.

References

- Johnson, R. (2022). Advanced Fuel Storage Techniques for Industrial Diesel Generators. Power Engineering Quarterly, 56(3), 78-92.

- Smith, A., & Brown, T. (2023). Contamination Prevention in Large-Scale Diesel Fuel Systems. Journal of Energy Resources Technology, 145(2), 021301.

- Lee, S. et al. (2021). Comparative Analysis of Single vs. Dual-Fuel Generator Systems for Critical Infrastructure. Renewable and Sustainable Energy Reviews, 152, 111656.

- Garcia, M. (2023). Fuel Quality Management for High-Capacity Diesel Generators. Industrial Power Systems, 38(4), 412-425.

- Wilson, K., & Taylor, J. (2022). Optimizing Diesel Generator Performance through Advanced Fuel Storage Solutions. Energy Conversion and Management, 253, 115175.

- Zhang, L. et al. (2023). Innovations in Diesel Generator Fuel Supply Systems for Enhanced Reliability. Applied Energy, 330, 120305.