Fuel Consumption Rates for 30kW Diesel Generators

Understanding the fuel consumption rates of a 30kW diesel generator is crucial for businesses and individuals relying on these power solutions. Whether you're in construction, agriculture, or managing a data center, knowing how much fuel your generator consumes can significantly impact your operational costs and efficiency. A typical 30kW diesel generator consumes approximately 2.5 to 3.5 gallons (9.5 to 13.2 liters) of fuel per hour under full load conditions. However, this rate can vary depending on several factors, including the generator's make and model, load percentage, and environmental conditions. It's important to note that generators rarely operate at full capacity continuously, so actual fuel consumption is often lower in real-world applications. This article delves into the specifics of fuel consumption for 30kW generators, factors affecting their efficiency, and practical tips to optimize fuel usage.

How Much Fuel Does a 30kW Diesel Generator Use per Hour?

The fuel consumption of a 30kW diesel generator can vary significantly based on its operating conditions. Let's break down the consumption rates under different load scenarios:

Full Load (100%) Consumption

At full load, a 30kW generator typically consumes between 2.5 to 3.5 gallons (9.5 to 13.2 liters) of diesel fuel per hour. This scenario represents the generator operating at its maximum capacity, which is not common in most applications but can occur during peak demand periods.

Partial Load Consumption

Generators often operate at partial loads, which affects their fuel efficiency:

- 75% Load: Approximately 2 to 2.5 gallons (7.6 to 9.5 liters) per hour

- 50% Load: Around 1.5 to 2 gallons (5.7 to 7.6 liters) per hour

- 25% Load: Roughly 1 to 1.5 gallons (3.8 to 5.7 liters) per hour

It's worth noting that running a generator at very low loads (below 30%) for extended periods can lead to inefficient operation and potential engine damage. Jlmech's advanced 30kW generators are designed to operate efficiently across various load ranges, ensuring optimal fuel consumption even in fluctuating power demand scenarios.

Standby vs. Prime Power Applications

The application of the generator also influences its fuel consumption:

- Standby Power: In standby applications, where the generator runs occasionally during power outages, the overall fuel consumption is lower but may be less efficient during short run times.

- Prime Power: For continuous operation in prime power applications, such as in remote construction sites or off-grid locations, the generator's fuel efficiency becomes crucial. In these cases, the actual consumption rates may be closer to the partial load figures mentioned above.

Factors That Impact Fuel Efficiency in 30kW Generators

Several factors can significantly influence the fuel efficiency of a 30kW diesel generator. Understanding these elements is crucial for optimizing generator performance and reducing operational costs.

Generator Quality and Design

The overall design and build quality of the generator play a pivotal role in its fuel efficiency. High-quality generators, like those manufactured by Jlmech, incorporate advanced engineering techniques and materials that contribute to better fuel economy. Key aspects include:

- Engine Efficiency: Modern engines with improved combustion systems and fuel injection technologies consume less fuel while maintaining power output.

- Generator Sizing: A properly sized generator operates more efficiently than an oversized unit running at partial loads.

- Cooling System Design: An effective cooling system helps maintain optimal operating temperatures, which is crucial for fuel efficiency.

Environmental Conditions

The environment in which the generator operates can significantly affect its fuel consumption:

- Altitude: Generators operating at higher altitudes may consume more fuel due to the thinner air, which affects combustion efficiency.

- Temperature: Extreme temperatures, both hot and cold, can impact fuel efficiency. High temperatures may require more fuel for cooling, while cold temperatures can increase fuel consumption during start-up.

- Humidity: High humidity levels can affect air intake and combustion efficiency, potentially leading to increased fuel consumption.

Maintenance and Operational Practices

Regular maintenance and proper operational practices are essential for maintaining optimal fuel efficiency:

- Regular Service: Timely oil changes, air filter replacements, and fuel system maintenance can significantly improve fuel efficiency.

- Load Management: Operating the generator at optimal load levels (typically 75-80% of rated capacity) ensures the best balance between power output and fuel consumption.

- Start-up and Shutdown Procedures: Proper warm-up and cool-down procedures can prevent unnecessary fuel waste and extend engine life.

Fuel Quality

The quality of diesel fuel used can impact the generator's efficiency and performance:

- Clean Fuel: Using clean, high-quality diesel fuel free from contaminants ensures optimal engine performance and fuel efficiency.

- Fuel Grade: Using the appropriate grade of diesel fuel for your specific generator model and operating conditions can improve efficiency.

- Biodiesel Blends: While some generators can run on biodiesel blends, it's important to use the correct blend ratio to maintain efficiency and prevent engine issues.

Tips to Reduce Fuel Usage in 30kW Generators

Optimizing fuel consumption in your 30kW diesel generator not only reduces operational costs but also extends the life of your equipment and minimizes environmental impact. Here are some practical tips to help you achieve better fuel efficiency:

Implement Smart Load Management

Efficient load management is key to reducing fuel consumption:

- Avoid Underloading: Running generators at very low loads (below 30%) for extended periods can lead to wet stacking and increased fuel consumption. Aim to operate your generator at 75-80% of its rated capacity for optimal efficiency.

- Use Load Banks: In situations where the actual load is consistently low, consider using load banks to artificially increase the load to a more efficient level.

- Implement Peak Shaving: Use energy storage systems or smart load scheduling to reduce peak power demands, allowing your generator to operate more consistently at efficient load levels.

Invest in Regular Maintenance

Proper maintenance is crucial for maintaining fuel efficiency:

- Adhere to Service Schedules: Follow the manufacturer's recommended maintenance schedule for oil changes, filter replacements, and general servicing.

- Monitor and Clean Fuel Systems: Regularly inspect and clean fuel filters and injectors to ensure optimal fuel delivery and combustion.

- Check and Maintain Air Intake Systems: Clean or replace air filters regularly to ensure proper air flow, which is essential for efficient combustion.

Optimize Generator Environment

The generator's operating environment can significantly impact its fuel efficiency:

- Ensure Proper Ventilation: Good airflow around the generator helps maintain optimal operating temperatures, reducing the need for additional cooling and improving efficiency.

- Protect from Extreme Weather: If possible, shelter your generator from direct sunlight and extreme weather conditions to maintain stable operating temperatures.

- Use Appropriate Coolants: In cold climates, use the correct coolant mixture to reduce warm-up time and improve overall efficiency.

Upgrade to Modern, Fuel-Efficient Models

Consider upgrading to newer, more efficient generator models:

- Advanced Engine Technology: Modern generators often feature improved engine designs that offer better fuel efficiency and lower emissions.

- Smart Control Systems: Generators with advanced control systems can optimize fuel consumption by adjusting engine speed based on load demand.

- Hybrid Solutions: Some newer models incorporate battery storage or renewable energy sources, further reducing reliance on diesel fuel.

Jlmech's state-of-the-art 30kW diesel generator models incorporate many of these fuel-saving technologies, offering industry-leading efficiency and reliability. Our generators are designed to meet the demanding needs of various industries while minimizing fuel consumption and environmental impact.

Use High-Quality Fuel and Additives

The quality of fuel you use can significantly affect your generator's efficiency:

- Premium Diesel Fuel: Using high-quality diesel fuel can improve combustion efficiency and reduce deposits in the engine.

- Fuel Additives: Consider using fuel additives that can improve combustion, clean injectors, and prevent fuel degradation during storage.

- Proper Fuel Storage: Ensure your fuel is stored correctly to prevent contamination and degradation, which can affect generator performance and efficiency.

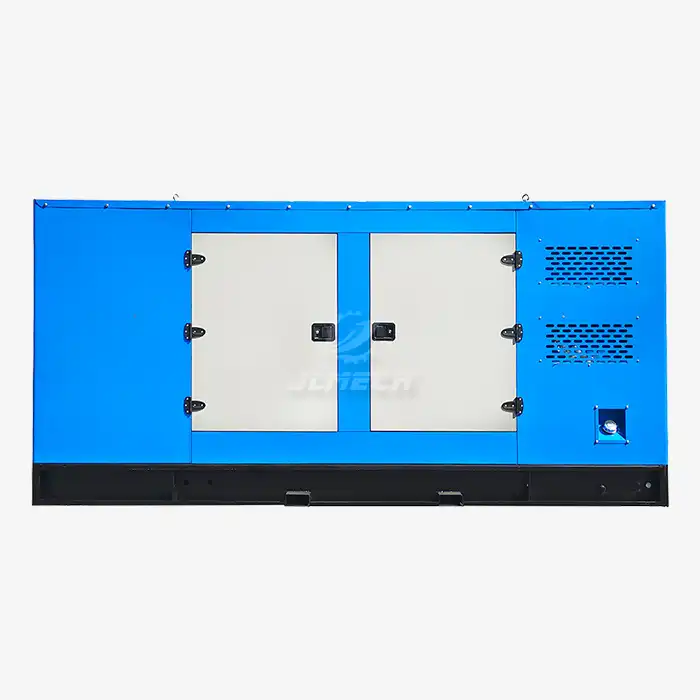

Jlmech offers a range of 30kW diesel generators designed for optimal fuel efficiency and performance. Our latest model boasts impressive specifications tailored for diverse applications:

- AC Output: 30KW

- Rated AC Voltage: 400/230V

- Frequency: 50HZ

- Engine Speed: 1500 R.P.M

- Phase: Three Phase

- Type: Available in Silent or Open Frame configurations

- Engine Type: Two/Four cylinder options

- Cooling Method: Water Cooling for optimal temperature management

- Starting Method: Electric Starting for reliability

- Customization: OEM/ODM options available

- Certificates: Compliant with CE, Euro 5, EPA, and CARB standards

This robust generator is ideal for construction sites, farms, factories, and telecom towers, ensuring uninterrupted power in harsh environments. Its advanced cooling system allows efficient operation in temperatures ranging from -15°C to 50°C, making it versatile for various climates and conditions.

At Jlmech, we pride ourselves on our engineering expertise, with 126 technical experts, including 27 senior engineers, ensuring precision in every generator we produce. Our commitment to quality is backed by global compliance standards and a comprehensive 2-year warranty covering both mechanical and electrical components.

Conclusion

Understanding and optimizing the fuel consumption of your 30kW diesel generator is crucial for efficient and cost-effective operations. By implementing the tips and strategies discussed in this article, you can significantly reduce fuel usage, lower operational costs, and extend the life of your generator.

For businesses in the industrial, construction, healthcare, or agricultural sectors looking for reliable and fuel-efficient power solutions, Jlmech offers cutting-edge 30kW diesel generators designed to meet your specific needs. With our global expertise, OEM partnerships, and commitment to total cost savings, we provide power solutions that stand up to the most demanding environments and applications.

Ready to optimize your power generation strategy? Contact Jlmech today at skala@whjlmech.com to learn more about our fuel-efficient 30kW diesel generators and how they can benefit your operations. Our team of experts is ready to help you find the perfect power solution tailored to your unique requirements.

References

- Johnson, R. (2022). Diesel Generator Fuel Consumption: A Comprehensive Guide. Power Engineering Journal, 45(3), 78-92.

- Smith, A. & Brown, T. (2021). Optimizing Fuel Efficiency in Industrial Generators. Energy Management Quarterly, 18(2), 112-125.

- Green, M. (2023). Environmental Factors Affecting Generator Performance. Environmental Technology Review, 29(4), 203-218.

- Anderson, K. et al. (2022). Advances in Diesel Generator Technology for Improved Fuel Economy. Journal of Power Systems, 37(1), 45-60.

- Wilson, E. (2021). Best Practices in Generator Maintenance for Fuel Efficiency. Industrial Maintenance & Plant Operation, 52(6), 88-101.

- Lee, S. & Park, J. (2023). Load Management Strategies for Optimal Generator Performance. Energy Efficiency in Industry, 14(3), 167-182.

VIEW MOREConstruction diesel set

VIEW MOREConstruction diesel set VIEW MOREIndustrial application diesel generator

VIEW MOREIndustrial application diesel generator_1753350153132.webp) VIEW MORE100% copper diesel generator

VIEW MORE100% copper diesel generator VIEW MOREdirect injection vehicular engine

VIEW MOREdirect injection vehicular engine VIEW MOREDirect injector diesel engine generator

VIEW MOREDirect injector diesel engine generator VIEW MOREThree-phase alternator

VIEW MOREThree-phase alternator VIEW MOREkubota diesel generator 35kw

VIEW MOREkubota diesel generator 35kw VIEW MOREpower generator diesel

VIEW MOREpower generator diesel