Can you megger a generator?

Yes, you absolutely can - and should - megger a generator! Insulation resistance testing (commonly known as "Megger testing") is not just possible but essential for maintaining optimal generator insulation integrity. This non-destructive diagnostic procedure helps identify moisture ingress, contamination, or aging in winding insulation, preventing catastrophic failures and unexpected downtime. For diesel generators operating in demanding environments, regular Megger testing represents a cornerstone of professional maintenance practice.

How to Perform a Megger Test

Safety First! Always de-energize the generator, isolate it from all power sources, and follow proper lockout/tagout procedures. Ensure complete discharge of windings to ground before and after testing.

Test Equipment:

Insulation resistance tester (Megger) with appropriate voltage rating

Personal protective equipment (insulated gloves, safety glasses)

Temperature and humidity measurement device

Step-by-Step Procedure:

Disconnect all external connections including cables, surge protectors and neutral grounds

Connect Megger's positive lead to generator stator windings

Connect negative lead to the grounded frame

Apply test voltage for standardized duration (typically 1 minute)

Record resistance values for each phase (phase-to-phase and phase-to-ground)

Note ambient temperature and humidity for reading correction

Critical consideration must be given to environmental conditions as temperature and humidity significantly impact generator insulation readings. Always correct measurements to standard baseline temperature using IEEE conversion formulas.

Interpreting Megger Readings

Understanding insulation resistance values is crucial for accurate assessment of generator insulation condition:

Acceptance Criteria:

Minimum acceptable values per IEEE standard: (Rated Voltage + 1000) / 1000 MΩ

Values below 0.1 MΩ indicate serious deterioration requiring immediate attention

Comparative analysis against previous readings and manufacturer specifications

Advanced Diagnostic Metrics:

Polarization Index (10-minute reading/1-minute reading)

Dielectric Absorption Ratio (30-second reading/60-second reading)

Temperature-corrected trend analysis over time

Typical insulation problems detectable through proper interpretation include moisture absorption, carbon dust contamination, oil infiltration, and insulation aging. A consistent downward trend in readings, even when values remain above minimum thresholds, often indicates progressing generator insulation degradation requiring proactive intervention.

Recommended Testing Frequency

Proactive testing prevents unexpected failures and extends generator life:

Routine Maintenance Testing:

Annual testing for standard operating conditions

Quarterly testing for harsh environments (high humidity, dust, contaminants)

Pre-commissioning tests for new installations

Condition-Based Testing:

After extended shutdown periods (>3 months)

Following repair or rewinding work

Post-exposure to adverse conditions (flooding, overheating)

When operational issues suggest insulation problems

Establishing comprehensive historical records of generator insulation test results enables predictive maintenance planning and helps identify deteriorating trends before failures occur. Documentation should include corrected values, environmental conditions, and operational context for each test.

Conclusion

Regular Megger testing provides invaluable insights into generator insulation condition, enabling predictive maintenance that prevents costly unplanned outages. When properly executed and interpreted, insulation resistance testing serves as your first line of defense against generator failure.

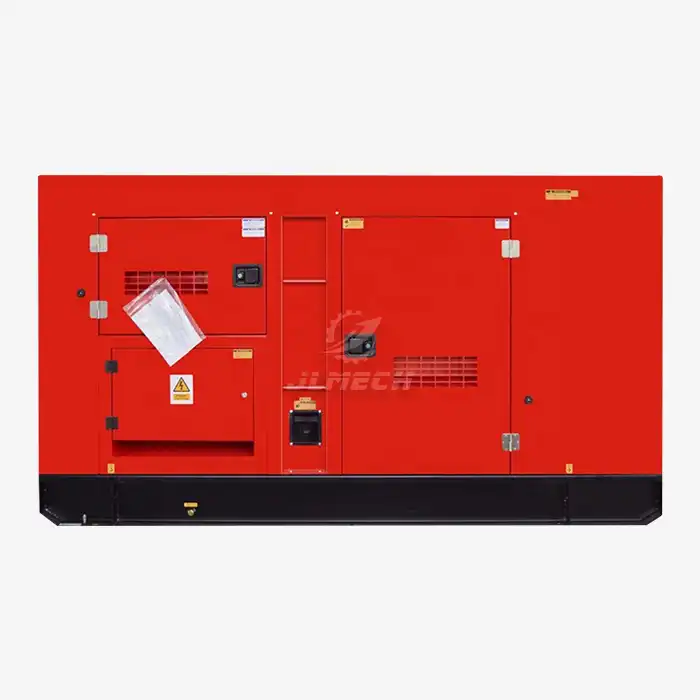

At JLMECH, we combine decades of generator manufacturing expertise with comprehensive field service capabilities. Our engineering team understands the critical importance of maintaining optimal generator insulation integrity and offers:

Professional insulation testing services following international standards

Detailed diagnostic reporting with actionable recommendations

Customized maintenance programs based on your specific operating conditions

Genuine replacement components and expert repair services

Contact our power solutions specialists today at skala@whjlmech.com to discuss your generator maintenance requirements. Let us help you develop a comprehensive testing and maintenance strategy that ensures reliability and extends equipment lifespan.

References

1. Institute of Electrical and Electronics Engineers. (2013). IEEE Std 43-2013: Recommended Practice for Testing Insulation Resistance of Electric Machinery.

2. International Electrotechnical Commission. (2018). IEC 60034-27-1: Rotating electrical machines - Insulation resistance test.

3. National Fire Protection Association. (2020). NFPA 70B: Recommended Practice for Electrical Equipment Maintenance.

4. Electrical Power Research Institute. (2021). Generator Maintenance Guide: Volume 3 - Diagnostic Testing.

5. American National Standards Institute. (2019). ANSI/NETA MTS-2019: Standard for Maintenance Testing Specifications.