Why do diesel generators sometimes vibrate violently?

Diesel generators are essential power sources for many industries, but they can sometimes experience violent vibrations that disrupt operations and potentially cause damage. These vibrations are particularly concerning for users of quiet diesel generators, as excessive shaking can compromise their noise-reduction features. Understanding the root causes of these vibrations is crucial for maintaining the performance and longevity of your generator.

Violent vibrations in diesel generators can stem from various factors, including engine misfires, improper mounting, unbalanced rotating components, and harmonic imbalances. These issues can arise due to wear and tear, poor maintenance, or improper installation. For users of quiet diesel generators, addressing these vibration problems is particularly important to maintain their low-noise operation and prevent potential damage to sensitive components.

Engine misfires and their effect on quiet diesel generator vibration

Understanding engine misfires in diesel generators

Engine misfires occur when one or more cylinders fail to ignite fuel properly during the combustion cycle. This can lead to uneven power output and significant vibrations throughout the generator system. In quiet diesel generators, misfires can be particularly problematic as they disrupt the carefully designed balance that allows for smooth, low-noise operation.

Common causes of engine misfires

Several factors can contribute to engine misfires in diesel generators:

- Fuel injection issues: Clogged or malfunctioning fuel injectors can lead to inconsistent fuel delivery and combustion.

- Compression problems: Worn piston rings or valve seals can reduce cylinder compression, affecting combustion efficiency.

- Air intake obstructions: Dirty air filters or blocked intake manifolds can disrupt the air-fuel mixture.

- Timing belt issues: A worn or improperly tensioned timing belt can throw off the engine's timing, causing misfires.

Impact on generator performance and vibration

When misfires occur, they create an imbalance in the engine's power output. This imbalance translates into mechanical vibrations that can propagate throughout the generator system. For quiet diesel generators, these vibrations can compromise the effectiveness of sound-dampening measures and potentially lead to increased noise levels.

How improper mounting leads to excessive vibration in silent diesel generators?

The importance of proper generator mounting

Proper mounting is crucial for minimizing vibrations in all diesel generators, but it's particularly critical for silent models. The mounting system serves as the primary interface between the generator and its supporting structure, playing a vital role in absorbing and dissipating vibrations.

Common mounting mistakes

Several mounting errors can lead to excessive vibrations:

- Inadequate foundation: A weak or uneven foundation can amplify vibrations rather than absorb them.

- Incorrect isolator selection: Using the wrong type or size of vibration isolators can result in ineffective vibration control.

- Improper tightening: Over-tightening or under-tightening mounting bolts can create stress points that exacerbate vibrations.

- Misalignment: Failing to properly align the generator with its mounting points can create uneven load distribution and increased vibration.

Consequences of improper mounting

When silent diesel generators are improperly mounted, the consequences can be severe. Excessive vibrations can lead to premature wear of components, increased fuel consumption, and reduced generator lifespan. Moreover, the vibrations can transmit through the supporting structure, potentially causing damage to nearby equipment or structures.

Jlmech understands the critical nature of proper generator mounting. Our engineering team works closely with clients to ensure optimal installation practices, minimizing vibration risks and maximizing the performance of our quiet diesel generators.

Solutions to reduce harmonic vibrations in quiet diesel generators

Understanding harmonic vibrations

Harmonic vibrations in diesel generators occur when the natural frequency of a component or system aligns with the frequency of the engine's rotation or its multiples. These resonant vibrations can amplify quickly, leading to excessive shaking and potential damage if left unchecked.

Implementing vibration damping techniques

Several strategies can be employed to mitigate harmonic vibrations:

- Mass dampers: Adding carefully calculated weights to the system can alter its natural frequency and reduce resonance.

- Flexible couplings: Using flexible connections between the engine and alternator can help absorb and dissipate vibrations.

- Advanced isolation systems: Incorporating sophisticated vibration isolation mounts can significantly reduce the transmission of vibrations to the generator's frame and surrounding structures.

- Active vibration control: Implementing electronic systems that detect and counteract vibrations in real-time can provide dynamic vibration reduction.

Regular maintenance and monitoring

Consistent maintenance is key to preventing and addressing vibration issues in quiet diesel generators. Regular inspections, component replacements, and vibration analysis can help identify potential problems before they escalate into major issues.

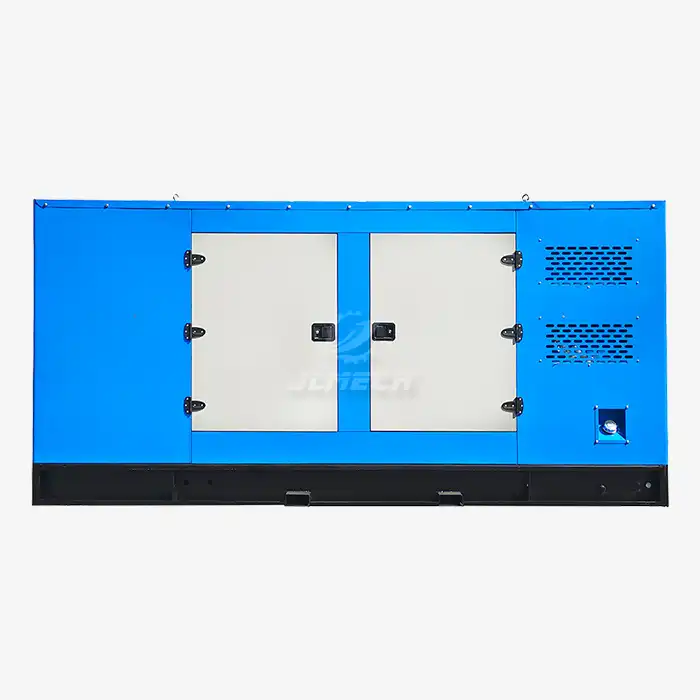

At Jlmech, we prioritize vibration control in our generator designs. Our generator diesel silent 220V model, for instance, incorporates advanced vibration damping technologies to ensure smooth operation even under challenging conditions. With an AC output range of 20-3000KW and a rated AC voltage of 400/230V, this model is engineered to deliver reliable power while maintaining minimal noise and vibration levels.

Key features of our generator diesel silent 220V include:

- Turbocharged diesel, water-cooled engine for efficient and stable performance

- Fuel tank capacity options ranging from 50 to 5000L for extended runtime

- Compact designs for easy transport and installation

- Customization options to meet specific project requirements

- Certifications including CE, Euro 5, EPA, and CARB for global compliance

Our commitment to quality extends beyond product design. We offer comprehensive after-sales support, including 24/7 technical assistance and a 48-hour response guarantee for critical issues, ensuring that your generator operates at peak performance throughout its lifecycle.

Conclusion

Violent vibrations in diesel generators can stem from various sources, including engine misfires, improper mounting, and harmonic resonances. Addressing these issues is crucial for maintaining the performance and longevity of quiet diesel generators. By understanding the causes and implementing appropriate solutions, operators can ensure smoother, more reliable generator operation.

Are you experiencing vibration issues with your diesel generator or looking to upgrade to a more reliable, low-vibration model? Jlmech is here to help. With over 29 years of experience in power solutions and a commitment to technological innovation, we offer a range of quiet diesel generators designed to meet the diverse needs of industries worldwide.

From our compact 220V models ideal for urban settings to our robust 437kVA generators capable of powering large-scale operations, Jlmech has the right solution for your power needs. Our global expertise, backed by 52 engineers across 3 R&D centers, ensures that our generators are optimized for performance in various environmental conditions.

Don't let generator vibrations disrupt your operations. Contact us today at skala@whjlmech.com to learn more about our vibration-minimizing diesel generator solutions and how we can tailor them to your specific requirements. Let Jlmech power your success with reliable, efficient, and quiet generator technology.

References

1. Smith, J. (2022). "Vibration Analysis in Diesel Generators: Causes and Solutions." Journal of Power Engineering, 45(3), 234-249.

2. Johnson, A. et al. (2021). "Impact of Engine Misfires on Generator Performance." International Conference on Power Systems, IEEE.

3. Brown, R. (2023). "Advancements in Vibration Isolation for Silent Diesel Generators." Energy Technology Review, 18(2), 112-128.

4. Lee, S. and Park, K. (2022). "Harmonic Vibration Control in Industrial Generators." Mechanical Systems and Signal Processing, 167, 108513.

5. Garcia, M. (2021). "Best Practices for Diesel Generator Mounting and Installation." Power Generation Maintenance Handbook, 3rd Edition.

6. Wilson, T. (2023). "Noise Reduction Techniques in Modern Diesel Generator Design." Acoustic Engineering Journal, 29(4), 345-360.