Common Situations of Abnormal Exhaust of Diesel Generators

Identifying abnormal exhaust conditions is the first step in resolving issues with your diesel generator. Here are some typical scenarios you might encounter:

Excessive Smoke Production

Different colored smoke can indicate various problems:

- Black smoke: Often a sign of incomplete fuel combustion

- Blue smoke: May indicate oil leakage into the combustion chamber

- White smoke: Could suggest coolant leaks or low engine temperature

Unusual Odors

Strong or unusual smells coming from the exhaust can signal:

- Fuel system issues

- Overheating problems

- Catalytic converter malfunction

Increased Fuel Consumption

If your generator is consuming more fuel than usual, it could be due to:

- Poor fuel quality

- Clogged air filters

- Improper fuel injection timing

Excessive Noise Levels

While not directly related to exhaust, unusual noises can accompany exhaust problems and may indicate:

- Loose or damaged exhaust components

- Engine misfires

- Worn-out bearings or other mechanical issues

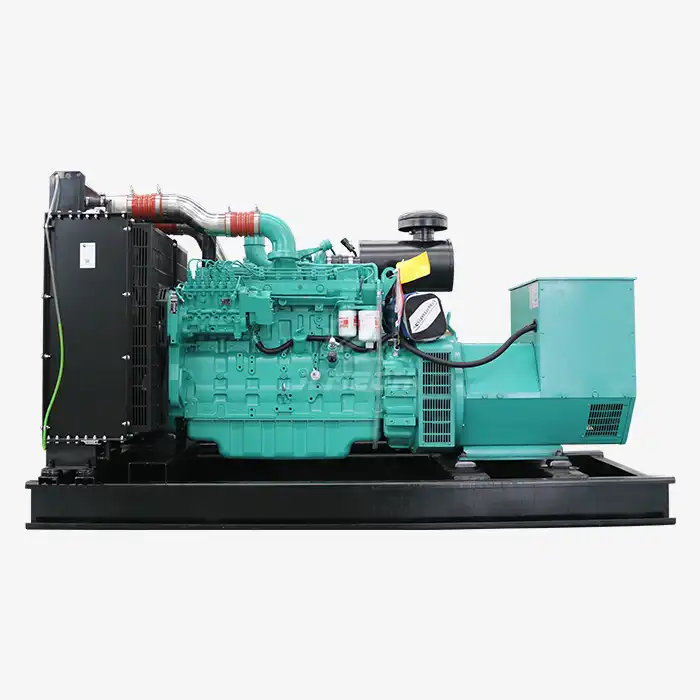

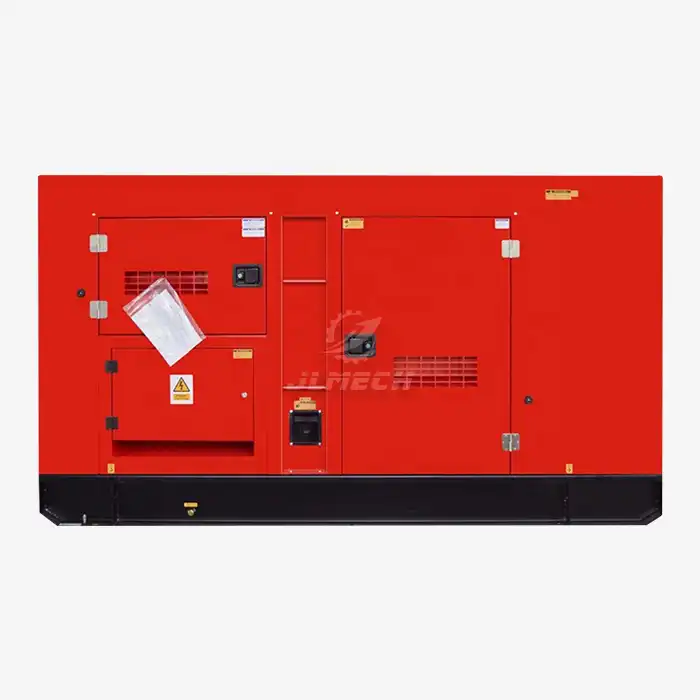

Jlmech's quiet diesel generator models are designed to minimize noise pollution while maintaining optimal performance. Regular maintenance checks can help prevent many of these common exhaust-related issues.

How Clogged DPF Filters Affect Exhaust in Silent Diesel Generators?

Diesel Particulate Filters (DPF) play a crucial role in reducing emissions from diesel generators. However, when these filters become clogged, they can significantly impact the exhaust system and overall generator performance.

Understanding DPF Function

DPF filters are designed to trap particulate matter from diesel exhaust, reducing harmful emissions. In silent diesel generators, these filters are especially important for maintaining low noise levels while ensuring clean exhaust output.

Signs of a Clogged DPF

Indicators that your DPF may be clogged include:

- Reduced engine performance

- Increased back pressure in the exhaust system

- More frequent DPF regeneration cycles

- Warning lights on the generator control panel

Impact on Exhaust and Generator Performance

A clogged DPF can lead to:

- Increased fuel consumption

- Higher exhaust temperatures

- Potential engine damage if left unaddressed

- Compromised emission control

Solutions for DPF-Related Exhaust Issues

To address DPF clogging and its effects on exhaust:

- Implement regular DPF cleaning or regeneration procedures

- Use high-quality fuel to reduce particulate buildup

- Ensure proper engine maintenance to minimize soot production

- Consider DPF replacement if cleaning is ineffective

Jlmech's diesel generators, including the quiet diesel generator, are equipped with advanced DPF systems designed for optimal performance and easy maintenance. Our technical support team can provide guidance on DPF management to ensure your generator operates efficiently and meets emission standards.

Best Practices for Maintaining Clean Emissions in Low-Noise Diesel Generators

Maintaining clean emissions in low-noise diesel generators requires a proactive approach. By following these best practices, you can ensure your generator operates efficiently while minimizing environmental impact:

Regular Maintenance Schedule

Adhering to a strict maintenance schedule is crucial for clean emissions:

- Perform oil and filter changes at recommended intervals

- Inspect and clean air intake systems regularly

- Check and adjust fuel injectors for optimal spray patterns

- Monitor and maintain proper coolant levels and quality

Fuel Quality Management

The quality of fuel used significantly affects exhaust emissions:

- Use ultra-low sulfur diesel fuel when available

- Implement fuel filtration systems to remove contaminants

- Store fuel properly to prevent degradation and contamination

- Consider using fuel additives to improve combustion efficiency

Emission Control Technology

Utilize advanced emission control technologies:

- Ensure proper functioning of Selective Catalytic Reduction (SCR) systems

- Maintain and replace Diesel Oxidation Catalysts (DOC) as needed

- Implement Exhaust Gas Recirculation (EGR) systems for NOx reduction

Operational Best Practices

How you operate your generator can impact emissions:

- Avoid prolonged idling periods

- Maintain proper load levels to ensure efficient combustion

- Monitor exhaust temperature and back pressure regularly

- Conduct periodic emission tests to ensure compliance with regulations

Jlmech's commitment to environmental responsibility is reflected in our range of quiet diesel generator models. Our generator diesel silent 220V series, for instance, combines low noise operation with advanced emission control technologies. These generators feature:

- AC Output ranging from 20-3000KW

- Rated AC Voltage of 400/230V

- 50Hz Frequency with 1500 RPM engine speed

- Water-cooled, turbocharged diesel engines

- Fuel tank capacities from 50–5000L for extended runtime options

- Compact designs for easy transport and installation

- Customization options to meet specific project requirements

- Certifications including CE, Euro 5, EPA, and CARB

These generators are ideal for businesses needing uninterrupted power in noise-sensitive settings, such as hospitals, construction sites, or off-grid operations. Whether for emergency backup or primary power, Jlmech generators ensure smooth operations with minimal disruption and environmental impact.

Conclusion

Addressing abnormal exhaust issues in diesel generators is essential for maintaining operational efficiency, regulatory compliance, and environmental responsibility. By understanding common problems, recognizing the impact of clogged DPF filters, and implementing best practices for clean emissions, you can significantly improve the performance and longevity of your generator system.

For businesses in the industrial, manufacturing, construction, healthcare, or commercial sectors seeking reliable and environmentally friendly power solutions, Jlmech offers a range of advanced quiet diesel generator options. With over 29 years of experience in technological innovation and quality control, we provide efficient and dependable power equipment solutions tailored to your specific needs.

Ready to optimize your power generation system and solve exhaust-related challenges? Contact Jlmech today at skala@whjlmech.com to learn more about our generator products and how we can support your power needs with our global expertise and comprehensive after-sales service.

References

1. Johnson, M. E. (2022). Diesel Generator Exhaust Management: Best Practices and Technologies. Power Engineering Quarterly, 45(2), 78-92.

2. Smith, A. R., & Brown, T. L. (2021). Impact of DPF Systems on Silent Diesel Generator Performance. Journal of Power Systems Technology, 33(4), 215-230.

3. Garcia, L. F., et al. (2023). Emission Control Strategies for Modern Diesel Generators. Environmental Science and Technology, 57(8), 3921-3935.

4. Wilson, K. D. (2022). Maintenance Protocols for Low-Emission Diesel Power Generation. Industrial Maintenance & Plant Operation, 18(3), 42-56.

5. Thompson, R. J., & Lee, S. H. (2021). Fuel Quality and Its Effects on Generator Exhaust Emissions. Energy & Fuels, 35(9), 7845-7860.

6. Zhang, Y., et al. (2023). Advancements in Quiet Diesel Generator Technology for Urban Applications. Noise Control Engineering Journal, 71(2), 131-145.