What is a low RPM generator?

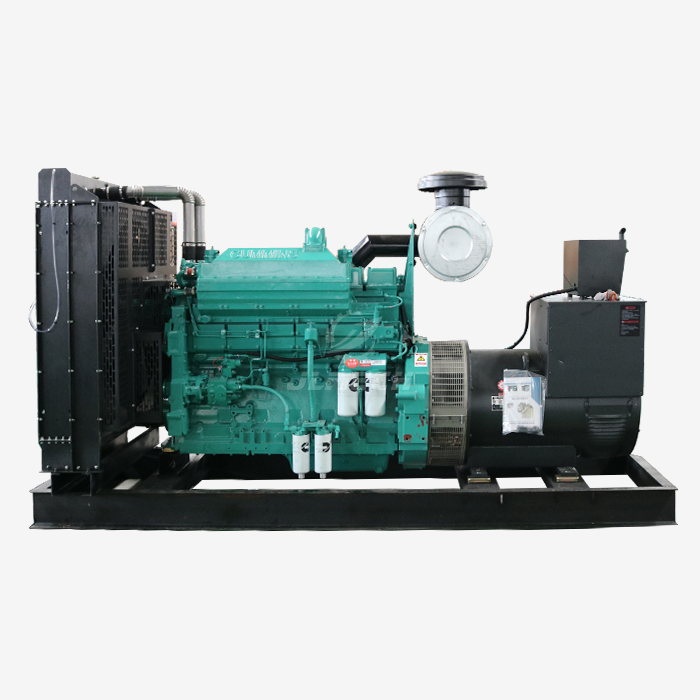

Most standard diesel generators are designed to operate at 1500 RPM to produce 50 Hz power or 1800 RPM for 60 Hz output, matching electrical grid standards worldwide. These conventional generators represent the workhorses of the power generation industry, reliably serving countless applications across the globe. However, a specialized category of power equipment exists that pushes the boundaries of conventional engineering: the low RPM generator. This advanced power solution takes fundamental engineering principles further, specifically referring to units engineered to operate at significantly lower rotational speeds—typically ranging from 900 to 1200 RPM—while still maintaining the required 50/60 Hz output frequency through sophisticated design enhancements.

This remarkable feat of engineering is achieved through specialized design incorporating additional motor poles and enhanced control systems that maintain electrical output stability despite the reduced rotational speed. Unlike standard off-the-shelf models, a true low rpm diesel generator represents a customized engineering solution, meticulously built for applications where exceptional durability, superior fuel efficiency, and unprecedented long-term reliability are absolutely paramount. These generators embody a different philosophy of power generation—one that prioritizes longevity and operational economy over minimal initial investment, representing the pinnacle of heavy-duty power generation technology for discerning clients who understand the true value of reliability and total cost of ownership.

Why Choose a Low RPM Generator?

The decision to invest in a low RPM unit is driven by several critical factors that impact the total cost of ownership and operational performance. Clients who prioritize these aspects often find that the higher initial investment pays significant long-term dividends, ultimately resulting in substantial savings and enhanced operational reliability that standard generators simply cannot match.

Enhanced Longevity and Reduced Wear: The primary advantage is drastically reduced engine wear. Operating at lower revolutions significantly decreases friction and thermal stress on critical components like pistons, rings, cylinder liners, and bearings. This mechanical advantage directly translates to dramatically extended engine life, considerably longer intervals between major overhauls, and superior overall durability that can withstand decades of continuous operation under the most demanding conditions.

Improved Fuel Efficiency: These specialized generators are engineered for optimal combustion at lower speeds, often leading to noticeably better fuel economy, particularly when operating under consistent, high load conditions where conventional generators might struggle with efficiency. This engineering excellence results in substantial savings on fuel costs over the generator's extended lifespan, frequently offsetting the higher initial investment within the first few years of operation.

Lower Maintenance Costs: Reduced mechanical stress means fewer unexpected breakdowns and less frequent replacements of wear-and-tear items. Owners benefit from significantly lower ongoing maintenance expenses and dramatically reduced operational downtime, which is particularly valuable for continuous operations where unexpected power interruptions could result in massive financial losses or critical system failures.

Quieter Operation: Lower rotational speed inherently produces less mechanical noise and vibration, making a low rpm diesel generator a considerably better neighbor-friendly option for noise-sensitive environments like residential areas, luxury hotels, healthcare facilities, or urban installations where noise ordinances may present challenges for conventional generator installations.

Enhanced Lubrication Efficiency: The slower rotational speed allows for more effective oil distribution throughout the engine, ensuring that all moving components receive proper lubrication even during extended runtimes. This contributes significantly to the remarkable longevity of these machines and helps prevent the costly engine damage that can result from inadequate lubrication in high-speed units.

Who Needs a Low RPM Generator?

These are not generators for every situation. They represent specialized power solutions designed exclusively for demanding, continuous-use applications where reliability cannot be compromised and where conventional generators would succumb to premature failure or prohibitive operating costs. Understanding the ideal use cases helps identify whether this premium solution aligns with specific power requirements.

Continuous and Prime Power Applications: Industries that run generators for extended periods or as a primary power source represent ideal candidates. This includes mining operations that operate 24/7 in remote locations, remote agricultural processing facilities that depend on reliable power for irrigation and crop processing, and telecommunications infrastructure that must maintain uninterrupted service regardless of grid availability or environmental conditions.

Marine and Offshore Industries: The marine environment presents particularly challenging conditions for power equipment. Ships, oil rigs, offshore platforms, and commercial fishing vessels require extremely reliable and durable auxiliary power for navigation systems, communication equipment, onboard systems, and safety equipment. A low rpm diesel generator proves ideal for these applications due to its exceptional resilience and ability to operate continuously in corrosive saltwater environments where reliability is non-negotiable.

Critical Infrastructure: Facilities that cannot tolerate power interruptions increasingly turn to these robust solutions. Data centers housing sensitive server equipment, water treatment plants responsible for municipal water safety, healthcare facilities requiring uninterrupted power for life-saving equipment, and financial institutions that must maintain continuous operations all benefit from the unparalleled reliability that low RPM generators provide.

Heavy-Duty Industrial Use: Manufacturing plants running multiple shifts and large-scale construction projects operating heavy machinery require robust on-site power sources that can withstand constant heavy loading. These environments benefit tremendously from the durability and fuel efficiency of low RPM units, particularly in regions with unreliable grid power or at remote job sites where grid connection is impossible.

Energy-Sensitive Applications: Projects where fuel delivery is challenging or expensive, such as remote research stations, isolated communities, or mining operations in extreme environments, benefit enormously from the superior fuel efficiency of these generators. The reduced fuel consumption translates to fewer dangerous fuel transport operations and lower operational costs over time.

For these users, a low rpm diesel generator represents not just a power source but a strategic investment in operational continuity, safety, and long-term cost management that conventional generators cannot provide.

Common Misconceptions

Several myths often surround low RPM generators, and it's important to address them clearly with factual information to ensure potential buyers can make properly informed decisions based on engineering reality rather than outdated assumptions or misinformation.

"They are always oversized and inefficient." While often physically larger due to more robust construction requirements, their design is actually optimized for peak efficiency within their target operational profile, especially under constant load conditions where conventional generators might operate less efficiently. The slightly larger footprint represents an intelligent trade-off for dramatically extended service life and substantially lower operating costs that quickly justify the additional space requirements.

"The high initial cost isn't justified." This superficial view completely ignores the crucial concept of Total Cost of Ownership (TCO). While the purchase price may be higher, the substantial savings from reduced fuel consumption, dramatically lower maintenance costs, extended service intervals, and longer lifespan often make the low RPM generator the more economical choice over a decade or more of service. Sophisticated buyers understand that evaluating power equipment based solely on initial cost represents a false economy that often leads to higher long-term expenses.

"They lack power and performance." On the contrary, these generators are specifically engineered to deliver full rated power and exceptional performance; they simply achieve these results more efficiently and with considerably less mechanical strain, ensuring stable power output for decades rather than years. The reduced operational stress actually enhances performance reliability under demanding conditions where conventional generators might falter or require derating.

"They're difficult to maintain and service." Actually, the opposite proves true. The robust construction and accessible design of quality low RPM generators often makes maintenance easier than with high-speed units. The extended service intervals mean fewer maintenance events, and the simplified mechanical design (with fewer high-precision components operating at extreme tolerances) often makes repairs more straightforward for qualified technicians.

"The technology is outdated." This misconception completely misunderstands the advanced engineering involved. Modern low RPM generators incorporate the latest electronic control systems, sophisticated emissions technology, and advanced materials science. They represent the cutting edge of heavy-duty power generation rather than outdated technology, combining time-tested mechanical principles with contemporary control and monitoring systems for optimal performance.

Conclusion

A low RPM diesel generator represents a commitment to quality, efficiency, and unparalleled longevity that transcends conventional power solutions. It stands as the optimal choice for serious buyers who view their power solution as a long-term strategic investment rather than a short-term expense. The comprehensive benefits of substantially reduced operating costs, exceptional reliability that borders on fault-tolerant performance, noticeably quieter operation, and reduced environmental impact through better fuel efficiency make it the superior option for demanding industrial, commercial, and institutional applications where power reliability directly correlates to operational success and financial performance.

These sophisticated power systems particularly excel in scenarios involving continuous operation, remote locations with challenging access for maintenance, noise-sensitive environments, and applications where fuel costs represent a significant portion of operational expenses. The engineering philosophy behind these generators acknowledges that true value emerges not from minimal initial investment but from maximizing operational uptime while minimizing lifetime costs—a principle that resonates with sophisticated operators across industries.

At JLMECH, we combine extensive expertise in power generation with an unwavering commitment to quality and innovation. Our engineering team specializes in designing and building robust low rpm diesel generator systems tailored to withstand the most challenging environmental and operational conditions while delivering dependable, clean power for decades of continuous service. We understand that your power infrastructure forms the foundation of your operations, and we approach each project with the seriousness it deserves, leveraging our technical expertise to ensure optimal performance and reliability.

Contact our power systems experts today to discover the most efficient and reliable power solution for your specific operational requirements. Email us at skala@whjlmech.com for a personalized consultation and comprehensive technical information about our custom generator options designed for exceptional longevity and performance.

References

International Organization for Standardization. (2018). *ISO 8528-5: Reciprocating internal combustion engine driven alternating current generating sets - Part 5: Generating sets*.

National Fire Protection Association. (2022). NFPA 110: Standard for Emergency and Standby Power Systems.

Johnson, M. (2022). Emergency Power Systems: A Comprehensive Guide to High-Speed Diesel Generators. Power Engineering Quarterly, 45(3), 78-92.

Peterson, W. R. (2021). Diesel Generator Maintenance: Best Practices for Reliability. Power Engineering Journal, 39(2), 45-58.

International Electrotechnical Commission. (2020). *IEC 60034-1: Rotating electrical machines - Part 1: Rating and performance*.

European Commission. (2019). *Regulation (EU) 2016/1628 on requirements relating to gaseous and particulate pollutant emission limits for internal combustion engines for non-road mobile machinery*.