What causes low RPM in a generator?

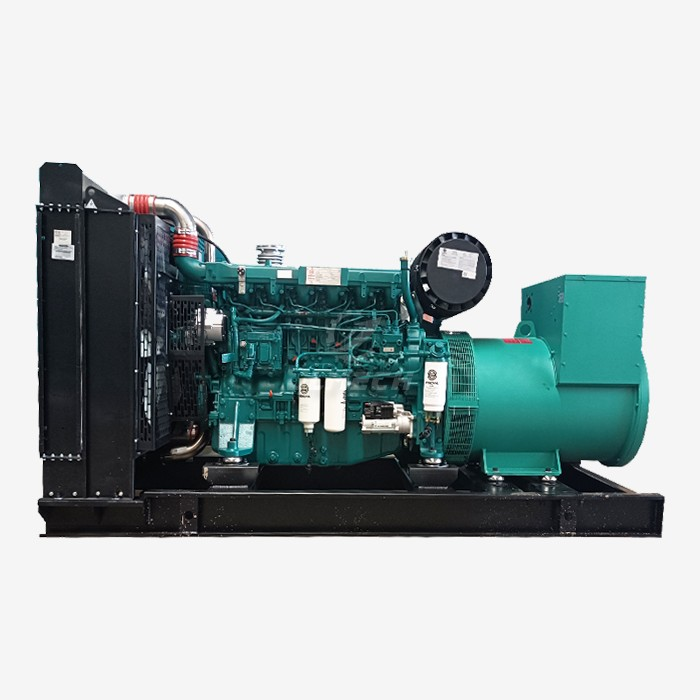

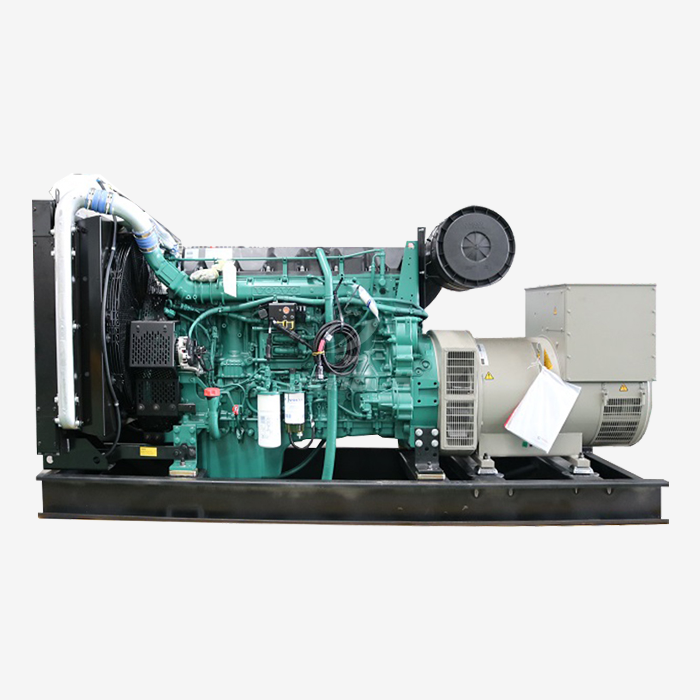

Most commercial and industrial diesel generators are designed to operate at either 1500 RPM (for 50 Hz systems) or 1800 RPM (for 60 Hz systems). These specific speeds are critical because they directly determine the output electrical frequency. Maintaining proper RPM is essential for generating stable voltage and frequency that matches your equipment's requirements. A low rpm diesel generator not only fails to perform efficiently but also risks damaging both itself and the connected loads.

Hazards of Low RPM Operation

Allowing your generator to operate at reduced RPM creates several serious risks:

Frequency Drop: The output frequency will fall below 50 Hz or 60 Hz, causing sensitive electronic equipment to malfunction or shut down.

Voltage Instability: Low RPM results in insufficient voltage output, which can damage motors and other inductive loads.

Engine Damage: Operating below rated speed causes incomplete combustion, leading to carbon buildup, increased wear, and potential overheating.

Generator Damage: The generator itself can overheat due to reduced cooling fan effectiveness and increased magnetic currents in the windings.

Increased Fuel Consumption: The engine operates less efficiently, burning more fuel to produce less power.

Ignoring a low rpm diesel generator problem quickly becomes costly in terms of both repairs and operational disruptions.

Common Causes of Low RPM

A generator's RPM is primarily controlled by the engine governor. The most frequent causes of low RPM include:

Fuel System Issues:

- Clogged fuel filters restricting flow

- Faulty fuel pump not delivering adequate pressure

- Air trapped in the fuel lines

- Poor fuel quality or water contamination

Air Intake Problems:

- Dirty air filter causing restricted airflow

- Blocked intake ducts or louvers

Mechanical Faults:

- Worn or malfunctioning engine governor

- Excessive engine friction due to poor lubrication

- Overloading beyond the generator's rated capacity

Electrical Issues:

- Failed capacitor or AVR (Automatic Voltage Regulator)

- Short circuits in the generator windings creating abnormal load

Identifying the root cause of your low rpm diesel generator is essential for implementing the correct solution.

Troubleshooting and Solutions

Addressing low RPM requires a systematic approach:

Immediate Actions:

- Reduce electrical load to see if RPM recovers

- Check for visible fuel leaks or air intake obstructions

- Verify the integrity of fuel and air filters

Basic Maintenance:

- Replace fuel and air filters according to maintenance schedule

- Drain water from fuel filters and fuel tank

- Check and change engine oil if needed

Professional Service Required:

- Calibrate or replace the engine governor

- Test and service the fuel injection system

- Conduct a complete electrical output test

- Perform a load bank test to verify performance under load

For persistent low rpm diesel generator issues, professional diagnosis and repair are recommended to prevent further damage.

Conclusion

Low RPM operation is a serious condition that requires immediate attention. While some causes can be addressed through basic maintenance, others require professional expertise to properly diagnose and repair. Regular preventive maintenance is the most effective strategy for avoiding low RPM problems and ensuring reliable generator performance.

At JLMECH, we combine extensive expertise in power generation with an unwavering commitment to quality and reliability. Our team specializes in diagnosing and resolving generator performance issues, ensuring your equipment operates at peak efficiency.

Our technical experts can help identify and resolve your RPM problems quickly and effectively. Email us at skala@whjlmech.com for professional assistance or to learn about our maintenance services designed to prevent these issues.

References

- International Organization for Standardization. (2018). *ISO 8528-5:2018 Reciprocating internal combustion engine driven alternating current generating sets - Part 5: Generating sets*.

- National Fire Protection Association. (2022). NFPA 110: Standard for Emergency and Standby Power Systems.

- Johnson, M. (2022). Emergency Power Systems: A Comprehensive Guide to High-Speed Diesel Generators. Power Engineering Quarterly, 45(3), 78-92.

- Peterson, W. R. (2021). Diesel Generator Maintenance: Best Practices for Reliability. Power Engineering Journal, 39(2), 45-58.