What are the effects of an excessively high or low oil level in a diesel generator?

The engine oil in your diesel generator serves as its lifeblood, performing critical functions beyond simple lubrication. It cools internal components, cleans contaminants, and seals combustion chambers. Both insufficient and excessive lubrication can lead to severe operational issues. Maintaining the correct Diesel Generator Oil Level is not merely a recommendation—it is a fundamental requirement for ensuring operational reliability, maximizing engine lifespan, and preventing costly mechanical damage.

The Critical Role of Engine Oil

Engine oil is a multi-component fluid essential for generator health. Its primary functions include:

Lubrication: Forming a protective film between moving metal parts to minimize friction and wear.

Cooling: Absorbing and carrying away heat from critical components like pistons and bearings.

Cleaning: Suspending soot, sludge, and other combustion by-products until they are filtered out.

Sealing: Helping to create a seal between piston rings and cylinder liners.

Any deviation from the optimal oil level compromises these vital functions, putting your entire power asset at risk.

Consequences of Low Oil Level

Operating your generator with an insufficient oil volume is a recipe for catastrophic failure. The immediate and long-term effects are severe:

Inadequate Lubrication & Accelerated Wear:

Metal-to-metal contact occurs between critical components like crankshaft journals, bearings, and piston rings.

This leads to rapid, often irreversible wear, scoring of cylinder walls, and potential engine seizure.

Overheating:

With less oil to absorb and transfer heat, engine temperatures soar.

This can result in overheating, thermal stress on components, and in extreme cases, piston melting or warping of cylinder heads.

Loss of Cleaning Action:

Reduced oil volume becomes saturated with contaminants more quickly, leading to sludge formation.

This sludge can clog oil passages and the oil filter, further starving the engine of lubrication.

Consequences of High Oil Level

Contrary to the "more is better" assumption, an overfilled crankcase creates a different set of dangerous problems:

Oil Aeration (Foaming):

The rotating crankshaft can whip excess oil, mixing air into it and creating foam.

Foamy oil is compressible, leading to a drop in oil pressure. This results in the same outcome as low oil—inadequate lubrication and potential bearing failure.

Increased Crankcase Pressure:

The crankshaft displaces air in an overfilled sump, causing a significant pressure buildup.

This forces oil past seals and gaskets, leading to leaks at the front and rear main seals, valve covers, and the crankcase breather.

Power Loss and Emissions:

The crankshaft rotating through a high oil level creates drag, causing a minor loss of engine power and efficiency.

Oil may be forced into the combustion chamber past piston rings, leading to blue exhaust smoke, increased emissions, and fouled spark plugs (in gas engines) or damaged injectors.

Maintaining the correct Diesel Generator Oil Level is therefore a precise balancing act, critical for avoiding both lubrication starvation and the damaging effects of overfilling.

Correct Oil Level Inspection Procedure

A proper check is the cornerstone of preventive maintenance. Follow these steps for an accurate reading:

Ensure a Level Surface: Park the generator on a flat, even plane. An inclined surface will give a false reading.

Shut Down and Cool: Always check the oil when the engine is shut down. For the most accurate reading, wait 5-10 minutes after shutdown to allow oil to drain back into the sump.

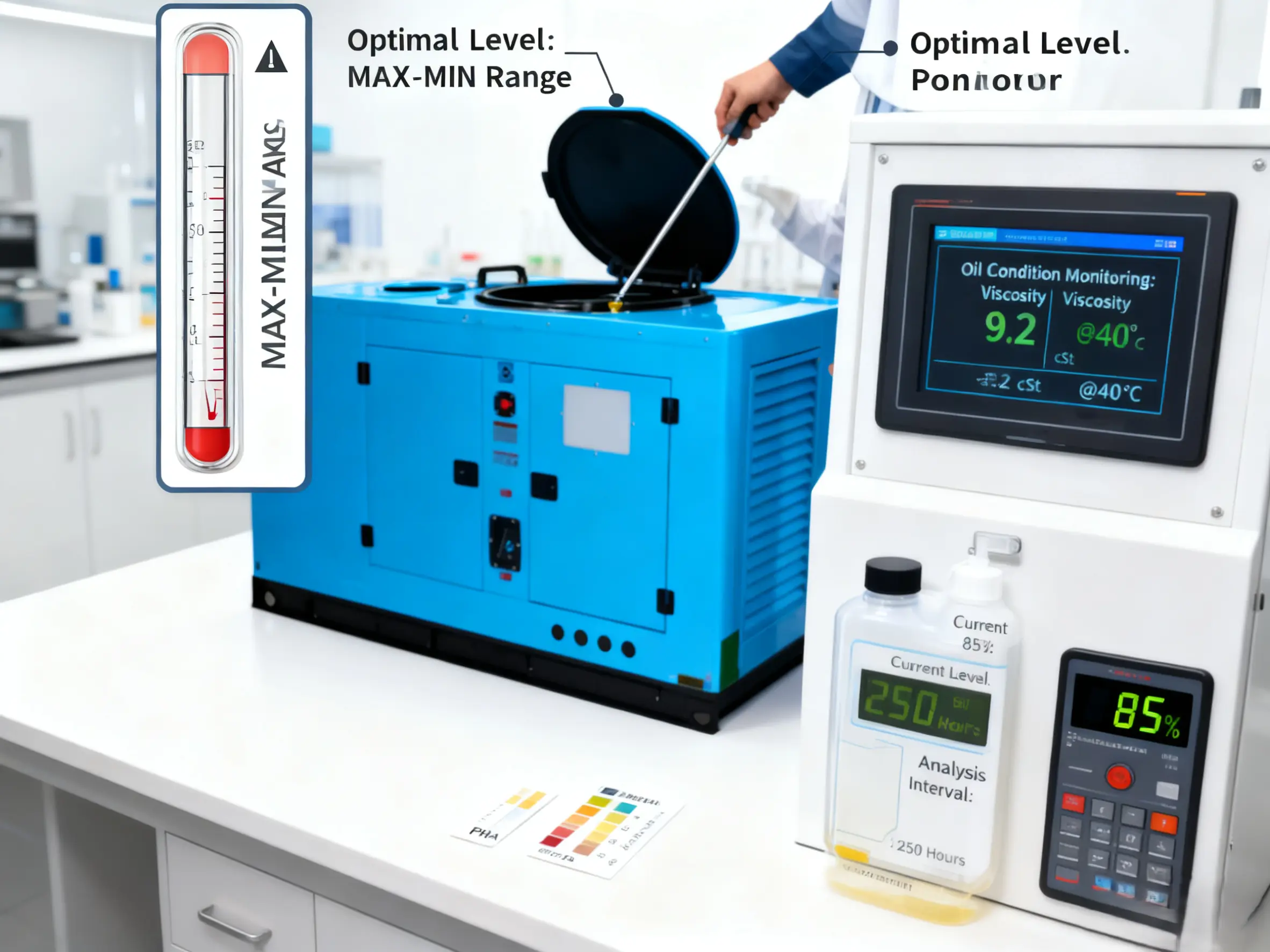

Use the Dipstick Correctly: Wipe the dipstick clean, reinsert it fully, then remove it to check the level. The oil mark should be between the "Low" (or "Min") and "High" (or "Max") indicators. The ideal level is near, but not exceeding, the "High" mark.

Action Steps for Incorrect Oil Levels

If you discover an abnormal oil level, take immediate and appropriate action:

For Low Oil Level:

Top up the oil immediately with the manufacturer-recommended grade and type.

Investigate the cause. Look for visible leaks or consider if the engine is consuming oil due to worn components.

For High Oil Level:

Do not start the engine. Running the generator with overfilled oil can cause immediate damage.

Use a fluid extraction pump to carefully remove the excess oil until the level is correct. If the engine was previously run with high oil, inspect for signs of leakage and check the crankcase breather for blockages.

Adhering to the specified Diesel Generator Oil Level range is a simple yet vital practice that safeguards your equipment's performance and longevity.

Conclusion

The implications of an incorrect oil level—whether too high or too low—are too significant to ignore. Consistent monitoring and maintenance are the most effective strategies for preventing unnecessary wear, avoiding unexpected breakdowns, and ensuring your diesel generator delivers reliable power for years to come.

Our technical support team is available to assist with all your generator maintenance and operational queries. For professional guidance, please contact us at skala@whjlmech.com.

References

Society of Automotive Engineers (SAE). (2020). Maintenance and Lubrication Standards for Stationary Diesel Engines (Standard No. SAE J1836_202010).

International Organization for Standardization. (2018). *Reciprocating internal combustion engines — Performance — Part 1: Declarations of power, fuel and lubricating oil consumptions (ISO 3046-1:2018)*.

Roberts, M. (2021). Proactive Maintenance Strategies for Industrial Generator Sets. Power Systems Engineering, 49(2), 34-48.