How to Match Diesel Generator Capacity to Peak Industrial Loads?

Matching industrial diesel generator capacity to peak industrial loads is crucial for ensuring uninterrupted power supply and operational efficiency. This process involves a careful assessment of power requirements, consideration of various factors influencing generator sizing, and implementation of effective load management strategies. By accurately determining the appropriate generator capacity, industries can avoid power shortages during peak demand periods while also preventing oversizing, which leads to unnecessary costs and reduced efficiency. This comprehensive guide will walk you through the essential steps and considerations for selecting the right diesel generator capacity to meet your industrial power needs.

Calculating Peak Load Requirements for Industries

Accurate calculation of peak load requirements is the foundation for selecting the appropriate industrial diesel generator capacity. This process involves a detailed analysis of power consumption patterns and anticipation of future growth.

Conducting a Load Study

A thorough load study is essential for determining the maximum power demand of your industrial facility. This study should include:

- Identifying all electrical equipment and their power ratings

- Analyzing historical power consumption data

- Measuring actual power usage during peak operational hours

- Considering seasonal variations in power demand

Utilize power monitoring devices to gather real-time data on energy consumption across different equipment and processes. This information will provide valuable insights into your facility's power usage patterns and help identify peak demand periods.

Accounting for Starting Loads

When calculating peak load requirements, it's crucial to consider starting loads, particularly for large motors and equipment. Starting loads can be significantly higher than running loads and may cause voltage dips if not properly accounted for. To address this:

- Identify equipment with high starting currents

- Calculate the combined starting load of simultaneously starting equipment

- Consider implementing soft starters or variable frequency drives to reduce starting loads

By accurately accounting for starting loads, you can ensure that your generator has sufficient capacity to handle these momentary power surges without compromising overall system stability.

Factors Influencing Generator Sizing Decisions

Several factors play a crucial role in determining the appropriate size of an industrial diesel generator for your specific application. Consider these key elements when making your sizing decision:

Environmental Conditions

The environment in which your generator will operate significantly impacts its performance and capacity requirements. Factors to consider include:

- Altitude: Higher altitudes reduce engine power output due to lower air density

- Ambient temperature: Extreme heat or cold can affect generator efficiency

- Humidity: High humidity levels can impact engine performance

- Dust and pollution: Harsh environments may require additional filtration systems

Adjust your generator sizing calculations to account for these environmental factors, ensuring optimal performance in your specific operating conditions.

Future Growth and Expansion

When sizing an industrial diesel generator, it's essential to consider potential future growth and expansion of your facility. This forward-thinking approach helps avoid the need for premature generator replacement or additional units as your power requirements increase. To account for future growth:

- Analyze your business expansion plans

- Estimate potential increases in power demand over the next 5-10 years

- Consider modular generator systems that allow for easy capacity expansion

By sizing your generator with future growth in mind, you can ensure long-term reliability and cost-effectiveness of your power solution.

Regulatory Compliance

Ensure that your generator sizing decisions comply with local, state, and federal regulations regarding emissions, noise levels, and safety standards. Consider:

- Emission standards: Select generators that meet or exceed current emission regulations

- Noise restrictions: Choose generators with appropriate sound attenuation features for your location

- Safety requirements: Adhere to all applicable safety codes and standards

Compliance with regulations not only ensures legal operation but also contributes to environmental responsibility and community relations.

Jlmech, a leading manufacturer of industrial diesel generators, offers a range of solutions designed to meet diverse regulatory requirements while delivering optimal performance. Their experienced team can assist in selecting the right generator that aligns with your specific compliance needs.

Load Management Strategies for Efficient Generator Use

Implementing effective load management strategies can optimize the performance and efficiency of your industrial diesel generator, ensuring it meets peak demands while minimizing fuel consumption and wear.

Load Shedding and Prioritization

Load shedding is a crucial strategy for managing peak loads and preventing generator overload. This approach involves:

- Identifying non-essential loads that can be temporarily disconnected during peak demand periods

- Implementing automated load shedding systems to prioritize critical equipment

- Establishing a load priority hierarchy based on operational importance

By strategically shedding non-essential loads during peak periods, you can ensure that critical processes receive uninterrupted power supply while optimizing generator performance.

Parallel Operation and Load Sharing

For industries with varying load profiles or those requiring redundancy, parallel operation of multiple generators can provide an efficient solution. Benefits of parallel operation include:

- Improved load matching capabilities

- Enhanced system reliability through redundancy

- Flexibility to add or remove capacity based on demand

- Potential for improved fuel efficiency at partial loads

Implement advanced control systems to manage load sharing between parallel generators, ensuring optimal performance and longevity of each unit.

Regular Maintenance and Monitoring

Proper maintenance and continuous monitoring are essential for ensuring your generator operates at peak efficiency and can meet load demands consistently. Implement a comprehensive maintenance program that includes:

- Regular inspections and servicing of generator components

- Fuel system maintenance to ensure clean and efficient fuel delivery

- Load bank testing to verify generator performance under various load conditions

- Continuous monitoring of generator parameters for early detection of potential issues

By maintaining your generator in optimal condition, you can ensure its ability to handle peak loads reliably while maximizing its operational lifespan.

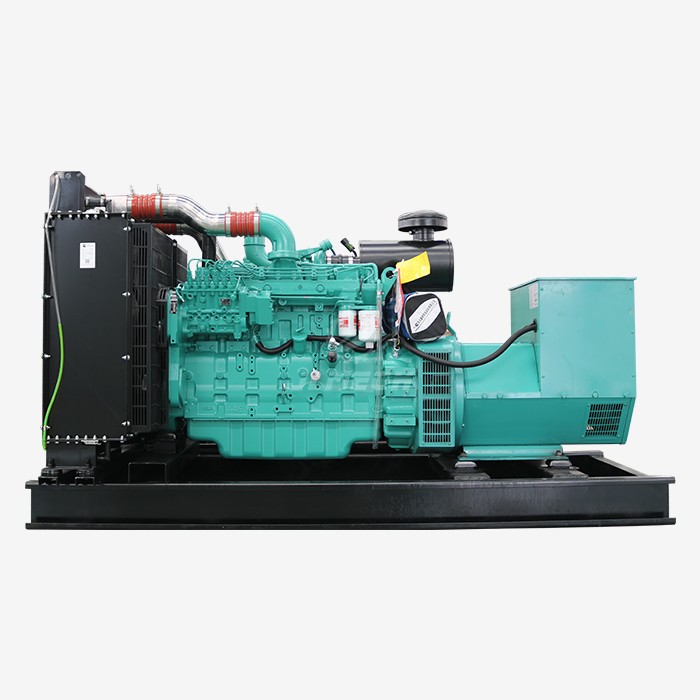

Jlmech's industrial diesel generators are engineered for exceptional performance and reliability. Their silent diesel generator 437kVA model exemplifies the company's commitment to meeting diverse industrial power needs. With a power output of 437kVA (350 kW), this generator is designed to handle substantial industrial loads while maintaining noise levels below 75 dB at 7 meters. This makes it ideal for noise-sensitive environments such as hospitals, urban construction sites, and data centers.

The generator features a robust six-cylinder engine with water cooling and electric starting, ensuring reliable performance in demanding industrial applications. Its compact dimensions of 3250mm x 1200mm x 1800mm, with trailer-mounted options available, provide flexibility for various installation requirements. The unit is certified to CE, ISO8528, and GB/T 2820-9 standards, guaranteeing compliance with international quality and safety regulations.

Jlmech's industrial diesel generator solutions are tailored to meet specific customer needs, with options for customization in frequency (60 Hz available) and generator brands. Their advanced acoustic enclosures not only reduce noise pollution but also contribute to a 20% improvement in fuel efficiency. With global compliance meeting EU Stage V and EPA Tier 4 emission standards, these generators are suitable for worldwide deployment, offering scalable solutions that can be customized with parallel systems, hybrid fuel compatibility, or weatherproofing features.

Conclusion

Matching diesel generator capacity to peak industrial loads is a complex process that requires careful consideration of various factors. By accurately calculating load requirements, considering influential factors, and implementing effective load management strategies, industries can ensure reliable power supply while optimizing efficiency and cost-effectiveness.

For industries seeking robust and efficient power solutions, Jlmech offers a comprehensive range of industrial diesel generators designed to meet diverse power needs. With over 29 years of experience in power solutions, Jlmech has established itself as a trusted partner for more than 300 global clients across Europe, America, and Southeast Asia. Their commitment to technological innovation and strict quality control ensures the delivery of reliable and efficient power equipment solutions.

To learn more about how Jlmech's industrial diesel generators can meet your specific power requirements or to discuss customized solutions for your industrial application, please contact us at skala@whjlmech.com. Our team of experts is ready to assist you in selecting the optimal power solution for your industrial needs, ensuring uninterrupted operations and long-term reliability.

References

1. Johnson, A. R. (2021). Industrial Power Systems: Design and Implementation. Energy Engineering Press.

2. Smith, B. L. (2020). Diesel Generator Sizing for Industrial Applications. Power Engineering Journal, 45(3), 78-92.

3. Thompson, C. D. (2019). Load Management Strategies in Industrial Power Systems. Industrial Energy Management, 12(2), 145-160.

4. Garcia, M. E. (2022). Environmental Considerations in Industrial Generator Selection. Sustainable Energy Solutions, 8(4), 210-225.

5. Wilson, R. J. (2020). Regulatory Compliance for Industrial Power Generation. Energy Policy and Regulation Review, 18(1), 55-70.

6. Brown, K. L. (2021). Advances in Parallel Generator Operations for Industrial Applications. Power Systems Technology, 14(3), 180-195.

VIEW MOREOff grid generator

VIEW MOREOff grid generator VIEW MORE50Hz Diesel Generator

VIEW MORE50Hz Diesel Generator VIEW MOREFully Enclosed Generator Set

VIEW MOREFully Enclosed Generator Set VIEW MORE200kVA Silent Diesel Generator

VIEW MORE200kVA Silent Diesel Generator VIEW MORESemi-automatic diesel generator

VIEW MORESemi-automatic diesel generator VIEW MOREpower plants diesel generator water cooled silent

VIEW MOREpower plants diesel generator water cooled silent VIEW MOREdiesel generator with ats

VIEW MOREdiesel generator with ats VIEW MORE3 phase perkins generator 60kva diesel generator

VIEW MORE3 phase perkins generator 60kva diesel generator