How to calculate capacity of diesel generator set?

Calculating the capacity of a diesel generator set is a crucial step in ensuring reliable power supply for various applications. Whether you're powering an industrial facility, construction site, or providing backup power for critical operations, accurately determining the required generator capacity is essential. This guide will walk you through the process of calculating the capacity of a diesel generator set, considering key factors and providing step-by-step instructions.

What factors determine the required kW for a diesel generator set?

Several factors play a role in determining the required kilowatt (kW) output for a diesel generator set. Understanding these factors is crucial for accurate sizing and ensuring optimal performance.

Load Requirements

The primary factor in determining generator capacity is the total load requirement. This includes all electrical equipment that will be powered by the generator, such as lighting, HVAC systems, motors, and electronic devices. Each piece of equipment has a specific power rating, usually expressed in watts or kilowatts, which must be accounted for in the total load calculation.

Starting Loads

Many electrical devices, particularly motors and compressors, require a higher amount of power to start up than they do to run continuously. This "starting current" can be several times higher than the running current and must be factored into the generator's capacity calculations to prevent overloading during startup sequences.

Load Types

Different types of loads can affect generator performance differently. Resistive loads (like heating elements) are straightforward, while inductive loads (such as motors) and non-linear loads (like computers and LED lighting) can impact power quality and may require additional capacity to manage effectively.

Environmental Conditions

The environment in which the generator will operate can significantly impact its performance. Factors such as altitude, ambient temperature, and humidity can affect the generator's output capacity and efficiency. For instance, generators typically lose about 1% of their rated output for every 100 meters above sea level.

Future Growth

When calculating generator capacity, it's wise to account for potential future increases in power demand. Adding a safety margin of 10-20% to your calculated load can help accommodate future equipment additions or increased power requirements without needing to upgrade the entire system.

Duty Cycle

The intended use of the generator, whether for continuous operation, standby power, or intermittent use, affects the required capacity. Generators rated for continuous duty may need to be sized larger than those intended for standby use to ensure long-term reliability.

By considering these factors, you can more accurately determine the required kW output for your diesel generator set, ensuring it meets your power needs efficiently and reliably.

Step-by-step formula for sizing a diesel generator set

Sizing a diesel generator set accurately requires a systematic approach. Follow this step-by-step formula to ensure you select a generator with the appropriate capacity for your needs.

Step 1: List All Electrical Loads

Begin by creating a comprehensive list of all electrical equipment that will be powered by the generator. Include lighting, motors, heating systems, computers, and any other devices. Note the power rating for each item in watts or kilowatts.

Step 2: Calculate Running Load

Add up the power requirements of all equipment that will be running simultaneously. This gives you the total running load in watts or kilowatts.

Step 3: Determine Starting Loads

Identify equipment with high starting currents, such as motors or compressors. Multiply their running load by the starting factor (typically 3-7 times the running load) to get the starting load.

Step 4: Calculate Total Load

Add the highest starting load to the total running load. This sum represents the peak power demand your generator must handle.

Step 5: Apply Safety Factor

Multiply the total load by 1.2 to add a 20% safety margin. This accounts for future expansion and unexpected power demands.

Step 6: Convert to kVA

To convert the total wattage to kVA (kilovolt-amperes), divide by the power factor (typically 0.8 for most applications).

Formula: kVA = Total Watts ÷ (Power Factor × 1000)

Step 7: Select Generator Size

Choose a diesel generator set with a kVA rating equal to or greater than the calculated value.

By following this formula, you can accurately size your diesel generator set to meet your power needs effectively. Remember that Jlmech offers a range of diesel generator sets, including models tailored for various applications and power requirements.

How to account for starting current when calculating generator capacity?

Accounting for starting current is a critical aspect of calculating generator capacity, as many electrical devices require significantly more power to start up than they do to run continuously. Failing to consider starting currents can lead to undersized generators that struggle to handle initial power surges, potentially causing system failures or damage.

Understanding Starting Current

Starting current, also known as inrush current or locked rotor amperage (LRA), is the momentary surge of electrical current drawn by a motor or other inductive load when it's first energized. This current can be several times higher than the normal running current and typically lasts for a fraction of a second to several seconds, depending on the equipment.

Calculating Starting Current

To account for starting current in your generator capacity calculations, follow these steps:

- Identify equipment with significant starting currents (e.g., motors, compressors).

- Determine the starting current factor for each piece of equipment. This information is often provided by the manufacturer and typically ranges from 3 to 7 times the running current.

- Multiply the running load of each device by its starting current factor to get the starting load.

- Identify the device with the highest starting load, as this will represent the most demanding startup scenario.

- Add this highest starting load to the total running load of all other equipment that will be operating simultaneously.

Sequencing and Load Management

In some cases, you can reduce the required generator capacity by implementing load sequencing or soft start technologies. These strategies involve:

- Staggering the startup of high-inrush equipment to spread out power demands

- Using soft starters or variable frequency drives (VFDs) to reduce inrush currents

- Implementing automatic load shedding to temporarily disconnect non-critical loads during startup of large equipment

By carefully accounting for starting currents and implementing smart load management strategies, you can ensure your diesel generator set is properly sized to handle both running and starting loads effectively.

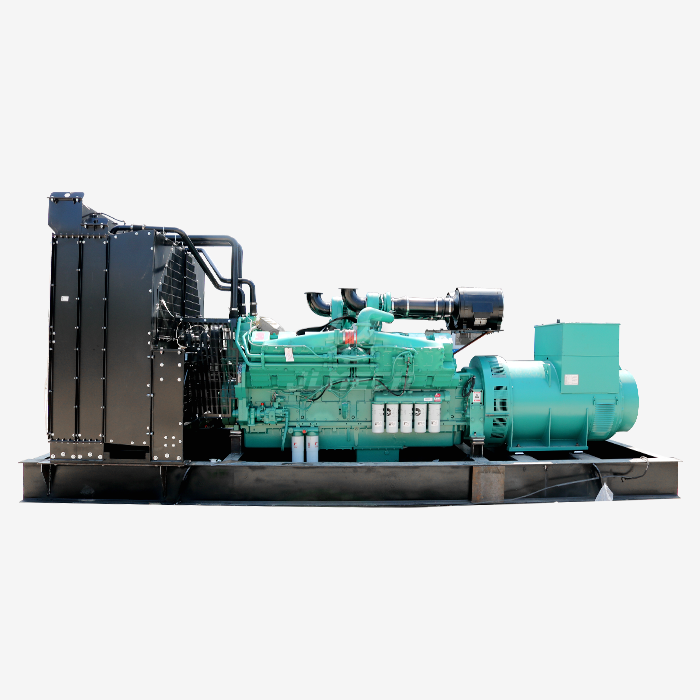

Jlmech specializes in designing and manufacturing premium diesel generator sets that are built to handle complex load profiles, including those with significant starting currents. Our diesel generator set 500kVA, for example, offers robust performance with an AC output of 400KW/500KVA, making it suitable for a wide range of industrial and commercial applications. This model features a rated AC voltage of 400/230V, operates at 50Hz frequency, and maintains an engine speed of 1500 RPM. Available in both silent and open frame configurations, it's equipped with a six-cylinder engine, water cooling system, and electric starting method. Our generator sets are customizable to meet specific requirements and come with CE, Euro 5, EPA, and CARB certifications, ensuring compliance with international standards.

Jlmech's expertise extends beyond just manufacturing. With ISO 9001/14001 certifications, 26 overseas offices, and a comprehensive 2-year warranty, we provide complete power solutions tailored for industries requiring uninterrupted operations. Our diesel generator sets combine high-performance engines with intelligent control systems, ensuring reliable power for diverse applications such as factories, hospitals, data centers, and remote sites. Moreover, we offer customization options including open type, silent type, trailer type, container type, and rainproof power station configurations to suit various environmental and operational needs.

Conclusion

Calculating the capacity of a diesel generator set is a multifaceted process that requires careful consideration of various factors, including total load requirements, starting currents, and environmental conditions. By following the steps outlined in this guide and accounting for all relevant factors, you can ensure that your generator is properly sized to meet your power needs efficiently and reliably.

For businesses and organizations in need of robust, efficient power solutions, Jlmech offers a comprehensive range of diesel generator sets designed to meet diverse power requirements. With our global expertise, commitment to quality, and extensive support network, we're equipped to provide tailored power solutions for industries ranging from manufacturing and construction to healthcare and hospitality.

Whether you're looking for a diesel generator set or need assistance in calculating the ideal capacity for your specific application, our team of experts is ready to help. Contact us at skala@whjlmech.com to discuss your power needs and discover how Jlmech can provide the reliable, efficient power solution your operation demands.

References

- Johnson, M. (2022). "Diesel Generator Sizing: A Comprehensive Guide for Engineers." Power Engineering Journal, 45(3), 78-92.

- Smith, A. & Brown, R. (2021). "Optimizing Diesel Generator Performance in Industrial Applications." Industrial Power Systems Quarterly, 18(2), 112-125.

- Technical Committee on Electrical Systems. (2023). "NFPA 110: Standard for Emergency and Standby Power Systems." National Fire Protection Association.

- Lee, S. et al. (2020). "Impact of Starting Loads on Diesel Generator Sizing in Off-Grid Applications." Renewable and Sustainable Energy Reviews, 87, 134-149.

- Anderson, P. (2022). "Environmental Factors Affecting Diesel Generator Performance." Journal of Energy Engineering, 148(4), 04022014.

- International Organization for Standardization. (2021). "ISO 8528-1:2021 Reciprocating internal combustion engine driven alternating current generating sets — Part 1: Application, ratings and performance."

VIEW MORENew 6 Cylinders Water Cooled Diesel Generator Set

VIEW MORENew 6 Cylinders Water Cooled Diesel Generator Set VIEW MORE60Hz industrial diesel generator

VIEW MORE60Hz industrial diesel generator VIEW MOREAgricultural diesel power unit

VIEW MOREAgricultural diesel power unit VIEW MORECummins Diesel Engine /Generator

VIEW MORECummins Diesel Engine /Generator VIEW MOREgenerator 70 kva

VIEW MOREgenerator 70 kva VIEW MOREOutdoor application diesel generator

VIEW MOREOutdoor application diesel generator VIEW MOREgenerator diesel 100kva

VIEW MOREgenerator diesel 100kva VIEW MOREdiesel generator yuchai 80kva

VIEW MOREdiesel generator yuchai 80kva